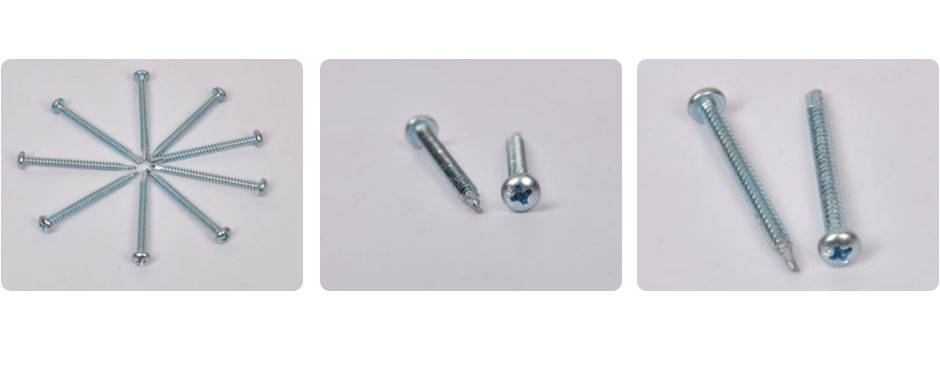

self drilling screw vs self tapping screw

Self-Drilling Screws vs. Self-Tapping Screws Understanding the Differences

When it comes to fastening materials, one of the most commonly debated topics in construction and manufacturing is the choice between self-drilling screws and self-tapping screws. While both types are essential in various applications, they serve different purposes and have distinct characteristics that can affect project outcomes.

Self-Drilling Screws

Self-drilling screws, often referred to as Tek screws, are designed with a drill bit-like point that allows them to create their own holes in the material being fastened. This feature eliminates the need for pre-drilling holes, saving time and labor in many applications. Self-drilling screws are particularly useful when working with metal, as they can easily penetrate thin sheets of steel and other materials without the risk of splitting.

The design of self-drilling screws includes a sharp, pointed tip that is effective at penetrating hard materials. Additionally, these screws are often threaded along the entire shaft, which provides superior holding power once installed. They come in various lengths, diameters, and materials, making them versatile for different environments, including outdoor and industrial use.

Self-Tapping Screws

In contrast, self-tapping screws do not have a drill point; instead, they come with a sharp tip that enables them to create their own threads in pre-drilled holes. This distinction means that while self-tapping screws can secure materials very effectively, they require an initial hole to facilitate their locking mechanism. The absence of a drill point makes self-tapping screws better suited for softer materials, such as plastic or wood.

self drilling screw vs self tapping screw

Self-tapping screws can be categorized into two main types standard and thread-forming. Standard self-tapping screws are designed for use in metals and involve cutting threads into the material, while thread-forming types create threads without cutting, making them ideal for softer substrates. The choice between these various types largely depends on the specific application and materials being used.

Key Differences

The primary difference between self-drilling and self-tapping screws lies in their application and functionality. Self-drilling screws are built for speed and efficiency, allowing users to work with less preparation time. They are especially beneficial in metal roofing, siding, and other applications where the material is too hard for traditional screws.

On the other hand, self-tapping screws require a bit more preparation, as they cannot create their own holes. They are ideal for applications where precision is key, and the user already has a drilled hole to work with. This makes them an excellent choice for assembling materials where a secure, tight fit is paramount.

Conclusion

Ultimately, the choice between self-drilling screws and self-tapping screws boils down to the specific needs of the project, the materials involved, and the level of efficiency required. Understanding the differences in their design and functionality will help users make informed decisions, ensuring optimal results in their fastening needs. Whether you're a DIY enthusiast or a professional contractor, knowing when to utilize each type of screw can lead to more successful and durable projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024