Self Drilling Screw Size Specifications for Manufacturers and Industry Standards

Understanding Self-Drilling Screw Dimensions A Guide for Manufacturers and Users

Self-drilling screws have become increasingly popular across various industries due to their unique design and functionality. Unlike standard screws that require a pre-drilled hole, self-drilling screws come equipped with a drill point that allows them to create their own hole as they are driven into the material. This feature not only saves time during installation but also enhances the overall efficiency of the assembly process. For manufacturers and users alike, understanding the dimensions of self-drilling screws is crucial for ensuring the right fit and function for specific applications.

The Importance of Dimensions

The dimensions of self-drilling screws play a vital role in determining their suitability for particular applications. These dimensions typically include the diameter, length, thread pitch, and head style, among others. Selecting the right dimensions is essential for achieving optimal performance and avoiding issues such as material damage, insufficient fastening, or potential failure of the assembly.

1. Diameter The diameter of a self-drilling screw is perhaps one of the most critical dimensions. Common diameters range from 6 to 14 for most applications, but screws can be found in larger sizes for heavy-duty tasks. A larger diameter provides greater grip, which is particularly important for materials with lower density, such as wood or softer metals.

2. Length The length of the screw must be appropriate for the thickness of the material being fastened. Using a screw that is too long can lead to material breakage, while a screw that is too short may not provide adequate holding strength. Generally, when choosing the length, it’s essential to consider the total thickness of the materials being joined, as well as any potential countersinking that may be required.

3. Thread Pitch The thread pitch of a screw refers to the distance between threads and can significantly impact the screw’s holding power. A finer thread pitch may provide more surface area contact, which is desirable in softer materials, whereas a coarser thread pitch can offer better anchorage in harder materials. Manufacturers typically offer self-drilling screws with varying thread pitches to meet the diverse requirements of different applications.

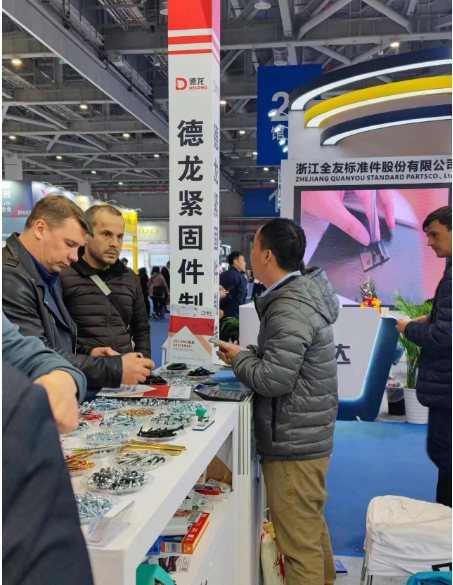

self drilling screw dimensions manufacturer

4. Head Style The head style of self-drilling screws varies based on the intended application. Common head styles include flat, pan, and hex heads. The choice of head style affects how the screw can be installed and provides influence over the aesthetic appearance of the finished product. For example, flat heads are suitable for countersinking, while pan heads are often used when a more prominent appearance is desired.

5. Material and Coating Self-drilling screws can be made from various materials, including steel, stainless steel, and even plastic, depending on the application's requirements. Additionally, coatings such as zinc plating or galvanization can enhance corrosion resistance, extending the lifespan of the screw, particularly in outdoor or marine environments.

Applications of Self-Drilling Screws

Self-drilling screws are widely used in multiple industries, including construction, manufacturing, and automotive. They are commonly employed in metal roofing installations, where the ability to drill through metal sheets without pre-drilling is particularly advantageous. Additionally, they are used in wood and composite material projects, including decking and fencing.

Conclusion

As manufacturers continue to innovate and improve self-drilling screw designs, understanding the dimensions is more critical than ever. By selecting the proper screw diameter, length, thread pitch, and head style, users can ensure a strong and reliable fastening solution for their specific needs. Whether for construction, manufacturing, or DIY projects, knowledge of self-drilling screw dimensions will ultimately contribute to more effective and efficient applications.

When sourcing self-drilling screws, it is essential to work with reputable manufacturers that provide detailed specifications and high-quality products. By prioritizing these considerations, both manufacturers and end-users can achieve optimal results in their fastening solutions, ensuring the integrity of their projects for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024