velj . 04, 2025 04:21

Back to list

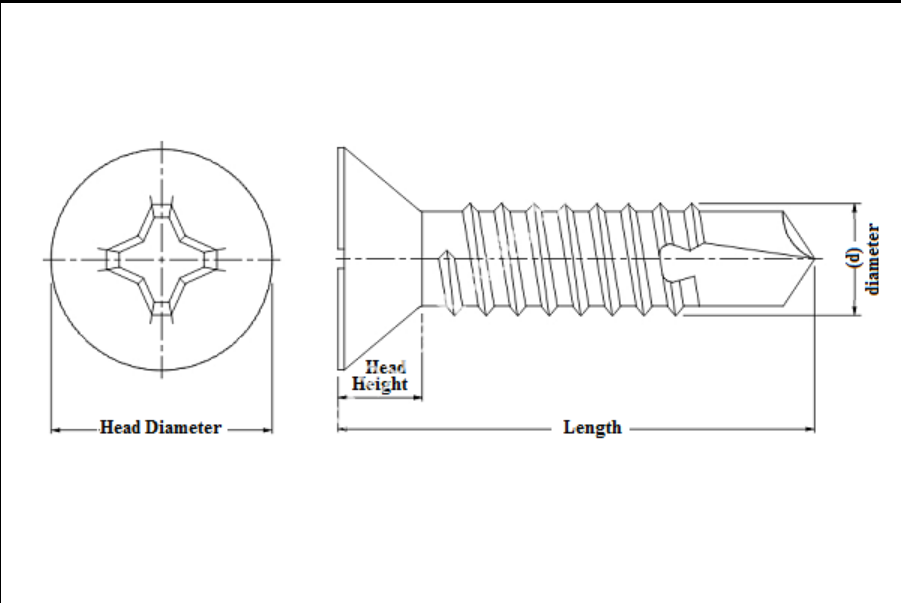

galvanized csk head self drilling screw

The capacity of self-drilling screws is a fundamental consideration in construction, manufacturing, and various DIY projects. This knowledge is crucial for ensuring structural integrity, safety, and durability of assembled products. A unique insight into this topic combines experience, expertise, authoritativeness, and trustworthiness, offering valuable information for both seasoned professionals and newcomers in the industry.

Field experience stresses the importance of installation techniques. Even with the right screw selection, improper installation can lead to failure. Adequate pressure, alignment, and speed during installation ensure that the screw does not wobble, strip, or break, which could compromise the overall strength of the connection. Professionals emphasize the use of quality tools and maintaining a consistent angle during installation to optimize performance. Furthermore, expert understanding is crucial when it comes to specific applications like roofing, metal framing, or cladding, where the load per screw must be precisely calculated. In these scenarios, manufacturers often provide recommended load data and torque specifications, which should be thoroughly understood and followed. This not only ensures compliance with safety standards but also enhances the credibility and authority of the professional on the job. Trust in self-drilling screws also comes from employing well-reviewed products from reputable brands. Product endorsements and certifications from industry standards organizations bolster confidence in the screw's capacity performance. Conclusively, while the fundamental purpose of self-drilling screws is straightforward, realizing their full potential involves an intersection of smart material choices, technical design understanding, environmental considerations, and skillful installation. Combining these aspects not only ensures optimal performance but also enhances safety and reliability, solidifying the user's role as a knowledgeable and trustworthy professional in the field.

Field experience stresses the importance of installation techniques. Even with the right screw selection, improper installation can lead to failure. Adequate pressure, alignment, and speed during installation ensure that the screw does not wobble, strip, or break, which could compromise the overall strength of the connection. Professionals emphasize the use of quality tools and maintaining a consistent angle during installation to optimize performance. Furthermore, expert understanding is crucial when it comes to specific applications like roofing, metal framing, or cladding, where the load per screw must be precisely calculated. In these scenarios, manufacturers often provide recommended load data and torque specifications, which should be thoroughly understood and followed. This not only ensures compliance with safety standards but also enhances the credibility and authority of the professional on the job. Trust in self-drilling screws also comes from employing well-reviewed products from reputable brands. Product endorsements and certifications from industry standards organizations bolster confidence in the screw's capacity performance. Conclusively, while the fundamental purpose of self-drilling screws is straightforward, realizing their full potential involves an intersection of smart material choices, technical design understanding, environmental considerations, and skillful installation. Combining these aspects not only ensures optimal performance but also enhances safety and reliability, solidifying the user's role as a knowledgeable and trustworthy professional in the field.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News