Self-Tapping Screws for Metal Applications and Installation Techniques

The Importance of ODM Self-Tapping Screws in Metal Applications

In the fast-evolving world of engineering and manufacturing, the demand for reliable and efficient fastening solutions is paramount. Among these solutions, ODM self-tapping screws stand out as a pivotal component in metalworking and assembly processes. Designed specifically to create their own threads when driven into metals, these screws have revolutionized the way we assemble and secure materials in various applications.

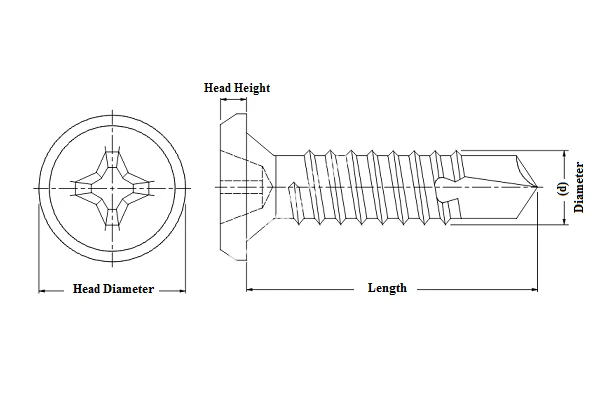

Understanding Self-Tapping Screws

Self-tapping screws are unique fasteners that are engineered to cut their own threads as they are installed into materials, eliminating the need for pre-drilled holes in many cases. This feature not only speeds up the assembly process but also enhances the structural integrity of the connection. ODM self-tapping screws are crafted with precision, ensuring they effectively penetrate and grip metal surfaces without compromising their strength or stability.

Advantages of ODM Self-Tapping Screws

1. Efficiency in Assembly One of the primary advantages of using ODM self-tapping screws in metal applications is the significant reduction in assembly time. Since these screws can create their own threads, many processes that would traditionally require additional steps, such as drilling or tapping, are streamlined. This not only saves time but also decreases labor costs.

2. Strong Mechanical Connection When inserted into metal, ODM self-tapping screws form a tight and durable connection. Their ability to engage with the material directly results in a robust fastening solution that can withstand various stresses and strains. This is particularly important in industries such as automotive, construction, and manufacturing, where strength and reliability are critical.

odm self tapping screw into metal

3. Versatility ODM self-tapping screws come in a variety of sizes, materials, and coatings to suit different metal applications. Whether dealing with thin sheets of aluminum or thicker steel panels, there is a self-tapping screw designed to meet the specific needs of the job. This versatility makes them ideal for a wide range of applications, from light fixtures to heavy machinery assemblies.

4. Cost-Effectiveness The efficiency and reliability of ODM self-tapping screws translate to cost savings in the long run. While the initial investment may vary, the reduction in labor costs and the potential for fewer failures or replacements makes these screws an economically smart choice for manufacturers and contractors.

Applications of ODM Self-Tapping Screws

The applications for ODM self-tapping screws are extensive. In the automotive industry, they are used to assemble body panels and structural components. In construction, they secure metal roofing and sidings, providing long-lasting durability against the elements. Additionally, in the manufacturing sector, these screws are frequently found in machinery and equipment assembly, ensuring that components remain securely fastened under operational conditions.

Conclusion

In conclusion, ODM self-tapping screws play an indispensable role in modern metal applications, offering efficiency, strength, and versatility. Their ability to streamline assembly processes and provide reliable connections makes them a preferred choice for various industries. As technology progresses and demands evolve, the importance of reliable fastening solutions like ODM self-tapping screws will only continue to grow, reflecting their integral role in the advancement of engineering and manufacturing practices. Whether it’s in everyday construction projects or complex machinery assembly, the impact of these screws is undeniable, symbolizing a significant leap forward in fastening technology.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024