Sizing Guidelines for Self-Tapping Screw Holes in China 2012 Standards

Understanding the Hole Size for Self-Tapping Screws in China A Comprehensive Overview

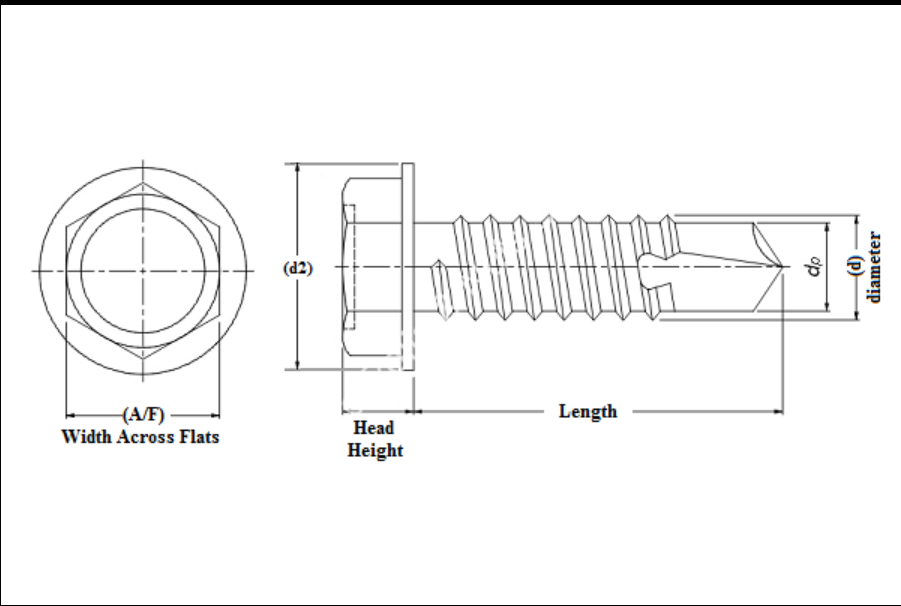

Self-tapping screws are essential fasteners in various industries, including construction, automotive, and electronics. The unique design of these screws allows them to create their own thread in materials, making them incredibly useful for applications where pre-drilled holes are impractical. However, understanding the appropriate hole size for self-tapping screws is crucial for ensuring optimal performance.

In China, the standards for self-tapping screws have evolved over the years, with a focus on quality and efficiency. The typical hole size for self-tapping screws can vary depending on several factors, including the type of material being fastened and the diameter of the screw itself. Generally, manufacturers recommend that the pilot hole for self-tapping screws should be approximately 75% to 80% of the screw diameter. This guideline helps in creating a snug fit that allows the screw to bite into the material effectively without causing excessive damage.

For instance, if a self-tapping screw has a diameter of 4 mm, the recommended pilot hole size would range from 3 mm to 3.2 mm. This ensures that the screw can easily penetrate the material while still maintaining a strong grip. In scenarios involving harder materials, a slightly larger hole might be necessary to prevent the screw from breaking during installation.

china 12 self tapping screw hole size

Additionally, the type of self-tapping screw also influences the required hole size. There are various types, including thread-cutting and thread-forming screws, each designed for specific applications. Thread-forming screws, for example, typically require a smaller pilot hole as they displace material to create threads, while thread-cutting screws can handle a slightly larger hole since they remove material as they are driven in.

Moreover, it is crucial for manufacturers and builders in China to comply with local standards and regulations when selecting hole sizes for self-tapping screws. Quality control measures should be in place to ensure the screws are made to specification, as this impacts not only the integrity of the assembly but also overall safety.

In conclusion, selecting the correct hole size for self-tapping screws is paramount for achieving strong, reliable connections in various applications. By adhering to recommended guidelines and understanding the specific requirements for different screw types and materials, users can optimize the performance and longevity of their assemblies in the ever-evolving industrial landscape of China.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024