High-Quality DIN125 Flat Carbon Steel Washers for Reliable Fastening Solutions

Understanding the Importance of DIN 125 Flat Carbon Steel Washers

In the world of engineering and construction, the seemingly simple components often play crucial roles in ensuring the stability and reliability of structures and machines. One such component is the DIN 125 flat washer, particularly those made from carbon steel. These washers are fundamental in providing load distribution, preventing damage to the surfaces being fastened, and aiding in the overall performance of mechanical assemblies.

What is a DIN 125 Flat Washer?

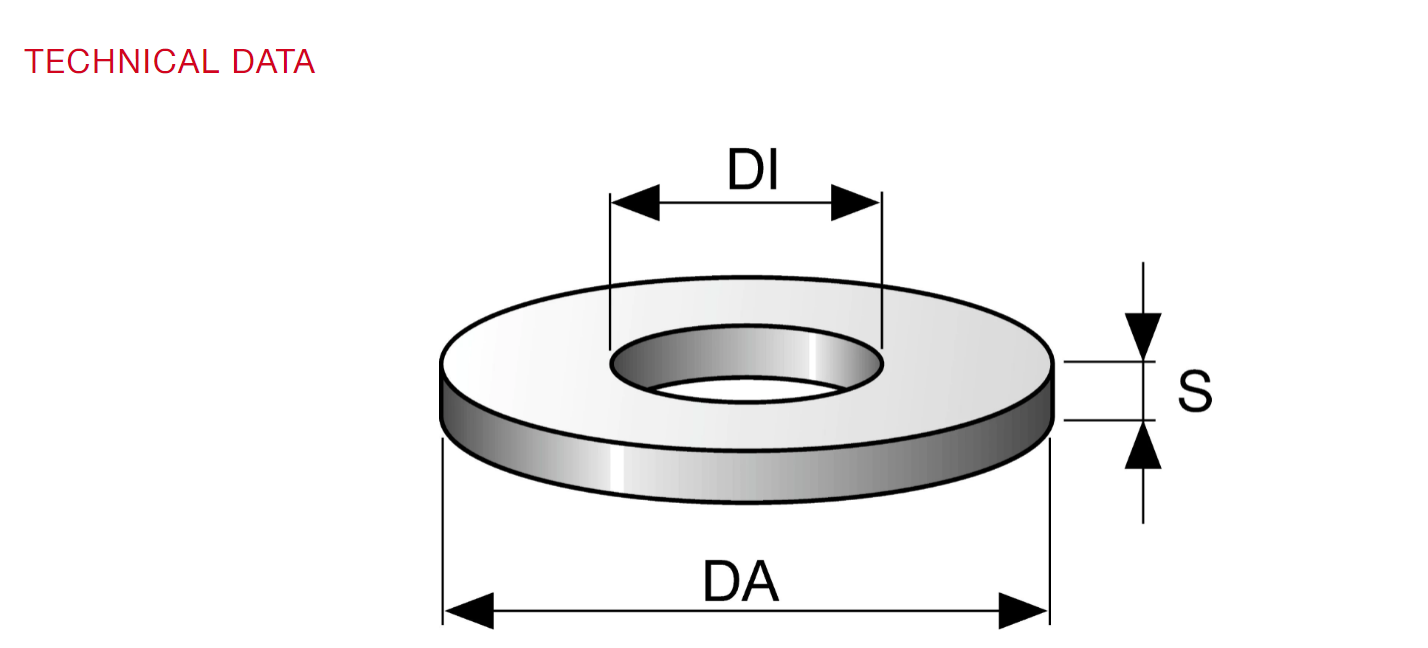

The DIN 125 designation refers to a specific standard established by the Deutsches Institut für Normung (German Institute for Standardization). DIN 125 flat washers are circular plates with a hole in the center, designed to be used with bolts, nuts, and screws. Their primary purpose is to distribute the load of the fastener over a larger area, which helps to prevent damage to the material being fastened, such as wood, metal, or plastic. By using a flat washer, the risk of deformation or pull-through failures is significantly minimized.

Why Choose Carbon Steel?

Carbon steel is a popular choice for manufacturing DIN 125 washers due to its excellent mechanical properties, affordability, and availability. Carbon steel offers a remarkable strength-to-weight ratio, making it suitable for various applications. Its tensile strength ensures that the washer can withstand significant loads without deforming or breaking.

Additionally, carbon steel can be treated with various coatings and finishes, such as zinc plating, to enhance its resistance to corrosion and environmental factors

. This makes carbon steel washers versatile, usable in both indoor and outdoor applications ranging from automotive to construction projects.best din125 flat carbon steel washer

Applications of DIN 125 Washers

DIN 125 flat washers are ubiquitous in various industries. In the automotive sector, they are commonly used to secure engine components, body panels, and suspension systems. In construction, they provide stability for beams, columns, and other structural elements, ensuring that everything stays securely fastened under load-bearing conditions.

Electrical applications also benefit from these washers, as they help secure wiring and fixtures while preventing damage to sensitive components. The versatility of DIN 125 flat washers makes them suitable for DIY projects as well, such as assembling furniture or home repairs.

Installation Considerations

When installing DIN 125 flat washers, it’s essential to choose the right size and thickness for the applications at hand. Using an appropriately sized washer ensures that it can effectively distribute the load without over-compressing or failing. Additionally, the surface material underneath the washer should be considered, as softer materials may require larger washers to prevent damage.

Conclusion

In summary, DIN 125 flat carbon steel washers play an essential role in numerous applications across various industries. Their ability to distribute loads, prevent damage, and enhance the durability of fastened joints makes them invaluable components. When selecting flat washers, it is important to consider the material, size, and application to ensure optimal performance. As engineering and construction demands continue to evolve, the reliance on dependable components like DIN 125 flat washers remains constant, ensuring safety and reliability in mechanical assemblies and structural integrity.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024