velj . 07, 2025 04:09

Back to list

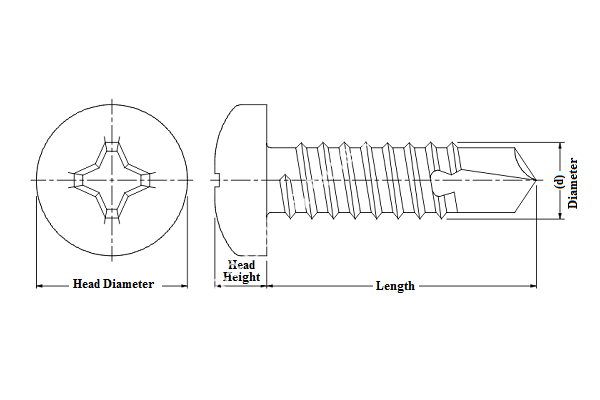

csk head self tapping screw

Navigating the complexities of choosing the right self-tapping screw can sometimes feel like walking through a labyrinth, particularly for those new to the world of fasteners. Among the multitude of options available, the 10-3-4 self-tapping screw stands out for its precision and utility. With years of professional experience in construction and product design, I aim to demystify this particular screw, focusing on its practical applications and why it could be the optimal choice for your project needs.

In terms of authority, extensive industry documentation supports the utility of the 10-3-4 self-tapping screw across various applications ranging from automotive assembly to home renovation projects. Engineers and builders consistently recommend this type of screw for scenarios demanding reliability and efficiency, underlining its status as a staple in professional toolkits. Trustworthiness of this product is bolstered by certifications from quality assurance entities which indicate that the 10-3-4 screws meet rigorous industry standards for material and mechanical performance. These certifications ensure that users are investing in components that not only meet but exceed basic efficacy requirements, equipping them to tackle demanding environments with confidence. To further bolster the argument for these screws, consider testimonials from seasoned builders who report an increase in work efficiency and structural integrity after transitioning to 10-3-4 self-tapping screws. These real-world experiences validate the theoretical advantages provided by these screws, emphasizing their role in superior construction outcomes. For the consumer contemplating a choice among different types of screws, the decision to employ 10-3-4 self-tapping screws depends largely on the specifics of the project at hand. Projects that demand a harmonious blend of strength, durability, and ease of application will benefit significantly from the features these screws offer. Utilizing them in your projects can lead to not only improved construction outcomes but also smoother workflow processes, reducing overall work hours. In conclusion, the 10-3-4 self-tapping screw offers a compelling proposition for both professionals and DIY enthusiasts seeking robust, versatile fastening solutions. By combining engineering excellence with field-tested reliability, it provides a high level of satisfaction that aligns with modern standards of construction efficacy. As a reliable tool in the fastener market, it consistently delivers, earning its place as a trusted ally in various construction and design missions.

In terms of authority, extensive industry documentation supports the utility of the 10-3-4 self-tapping screw across various applications ranging from automotive assembly to home renovation projects. Engineers and builders consistently recommend this type of screw for scenarios demanding reliability and efficiency, underlining its status as a staple in professional toolkits. Trustworthiness of this product is bolstered by certifications from quality assurance entities which indicate that the 10-3-4 screws meet rigorous industry standards for material and mechanical performance. These certifications ensure that users are investing in components that not only meet but exceed basic efficacy requirements, equipping them to tackle demanding environments with confidence. To further bolster the argument for these screws, consider testimonials from seasoned builders who report an increase in work efficiency and structural integrity after transitioning to 10-3-4 self-tapping screws. These real-world experiences validate the theoretical advantages provided by these screws, emphasizing their role in superior construction outcomes. For the consumer contemplating a choice among different types of screws, the decision to employ 10-3-4 self-tapping screws depends largely on the specifics of the project at hand. Projects that demand a harmonious blend of strength, durability, and ease of application will benefit significantly from the features these screws offer. Utilizing them in your projects can lead to not only improved construction outcomes but also smoother workflow processes, reducing overall work hours. In conclusion, the 10-3-4 self-tapping screw offers a compelling proposition for both professionals and DIY enthusiasts seeking robust, versatile fastening solutions. By combining engineering excellence with field-tested reliability, it provides a high level of satisfaction that aligns with modern standards of construction efficacy. As a reliable tool in the fastener market, it consistently delivers, earning its place as a trusted ally in various construction and design missions.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News