जनवरी . 14, 2025 12:26

Back to list

zinc plated chipboard screw

Zinc plated chipboard screws are a staple in the construction and DIY industries, offering unparalleled reliability and versatility. As an expert in fastener technology with years of hands-on experience, my goal is to illuminate the attributes that differentiate zinc plated chipboard screws and underscore their undeniable value in a plethora of applications.

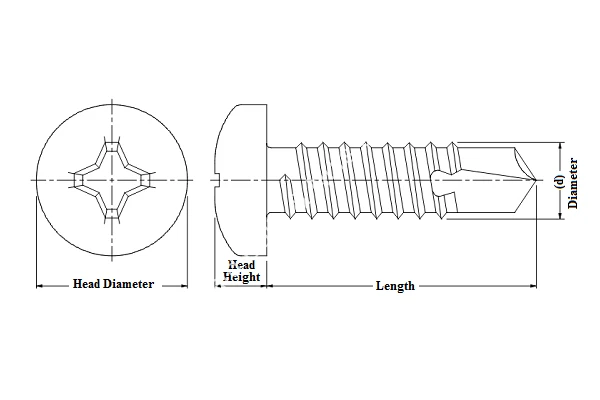

In addition to their physical characteristics, the standardization of zinc plated chipboard screws is another aspect worth noting. Available in a vast range of sizes and head types, these screws cater to any specific needs of a project. Flat head screws allow the screw to sit flush with or below the surface of the wood, while countersunk options are perfect when a completely smooth finish is required. They also come in various lengths and diameters, ensuring the perfect fit for every application, thereby enhancing their utility and efficiency. The process behind zinc plating itself is a testament to expertise in metallurgical engineering. By electroplating a thin layer of zinc onto a steel screw, manufacturers achieve a delicate balance between strength and resistance to environmental factors. This process not only improves the screw's functionality but also demonstrates a commitment to producing high-quality, reliable products. Choosing zinc plated chipboard screws also speaks to a sense of trustworthiness between supplier and customer. Leading manufacturers and suppliers practice stringent quality control measures, ensuring that each screw meets the highest standards before reaching the end user. This accountability is critical, especially in construction where the safety and longevity of a project can hinge on something as fundamental as a screw. In sum, zinc plated chipboard screws offer an exceptional blend of strength, durability, and corrosion resistance, making them indispensable in both professional and personal projects. Their proven track record in structural integrity, combined with the advanced engineering process of zinc plating, elevates them to an authoritative position within the fastener market. Whether for building, repairing, or crafting, these screws promise excellence and dependability with every application.

In addition to their physical characteristics, the standardization of zinc plated chipboard screws is another aspect worth noting. Available in a vast range of sizes and head types, these screws cater to any specific needs of a project. Flat head screws allow the screw to sit flush with or below the surface of the wood, while countersunk options are perfect when a completely smooth finish is required. They also come in various lengths and diameters, ensuring the perfect fit for every application, thereby enhancing their utility and efficiency. The process behind zinc plating itself is a testament to expertise in metallurgical engineering. By electroplating a thin layer of zinc onto a steel screw, manufacturers achieve a delicate balance between strength and resistance to environmental factors. This process not only improves the screw's functionality but also demonstrates a commitment to producing high-quality, reliable products. Choosing zinc plated chipboard screws also speaks to a sense of trustworthiness between supplier and customer. Leading manufacturers and suppliers practice stringent quality control measures, ensuring that each screw meets the highest standards before reaching the end user. This accountability is critical, especially in construction where the safety and longevity of a project can hinge on something as fundamental as a screw. In sum, zinc plated chipboard screws offer an exceptional blend of strength, durability, and corrosion resistance, making them indispensable in both professional and personal projects. Their proven track record in structural integrity, combined with the advanced engineering process of zinc plating, elevates them to an authoritative position within the fastener market. Whether for building, repairing, or crafting, these screws promise excellence and dependability with every application.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News