screw pattern for drywall ceiling company

Screw Pattern for Drywall Ceiling A Guide for Contractors and DIY Enthusiasts

When it comes to finishing a drywall ceiling, understanding the right screw pattern is crucial for ensuring a secure and flawless installation. Drywall, or gypsum board, is widely used in residential and commercial construction because of its ease of installation and versatility. However, improper fastening techniques can lead to a myriad of problems, including sagging, cracking, and, ultimately, a less-than-professional finish. This article explores the recommended screw patterns for drywall ceilings, key considerations, and tips for achieving the best results.

Why is Screw Pattern Important?

The screw pattern is vital for several reasons. First and foremost, it ensures that the drywall is properly secured to the underlying framing, which could be wooden joists or metal studs. A proper fastening technique minimizes the risk of movement between the drywall and the framing, thereby preventing cracks and other damage over time. Additionally, a well-distributed screw pattern helps to create a smooth surface, making it easier to finish with joint compound and tape.

Recommended Screw Pattern

For drywall ceilings, the most commonly recommended screw pattern is to place screws every 12 to 16 inches along the edges and every 16 inches in the field (the middle section of the drywall sheets). Specifically, here's a succinct approach to the fastening pattern

1. Edges Place screws about 8 to 12 inches apart along the edges of the drywall panels. This is essential because the edges are more susceptible to movement, and securing them effectively will prevent future issues.

2. Field In the field, screws should be installed every 12 to 16 inches apart. This spacing ensures that the center portion of the board is tightly held, reducing the likelihood of sagging.

3. Overlap and Staggering When installing multiple sheets of drywall, stagger the seams. This means that when two sheets meet, the screws should not align directly across from each other. Staggering the screws will help distribute forces more evenly and elevate the structural integrity of the installation.

screw pattern for drywall ceiling company

Additional Tips for Successful Installation

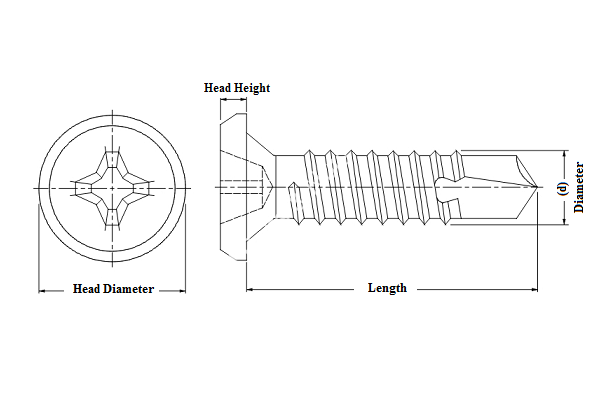

1. Type of Screws Use drywall screws specifically designed for ceiling applications. These screws typically have a bugle head and sharper points, making them easier to drive into the ceiling material. Moreover, consider using 1 1/4-inch screws for standard 1/2-inch drywall.

2. Avoid Over-Driving Over-driving screws can create dimples that will require extra sanding and finishing work. Use a screw gun with a depth-sensitive clutch to ensure that screws are driven flush with the surface without breaking the paper face of the drywall.

3. Consider Humidity In areas with high humidity, such as bathrooms or kitchens, utilize moisture-resistant drywall and appropriate screws. This will help reduce the risk of mold and deterioration.

4. Drywall Lifts For ceiling installations, a drywall lift can be extremely helpful. This tool raises the drywall to the ceiling and holds it in place while you fasten, making the entire process safer and more manageable.

5. Check for Level Before fastening, always check that your drywall sheets are level. Use a level tool and adjust as necessary to ensure a flat ceiling that won't warp after installation.

Conclusion

Installing drywall on a ceiling is a significant task, but with the right screw pattern and best practices in place, it can be accomplished successfully. By adhering to a recommended screw spacing of every 12 to 16 inches, staggering seams, and utilizing the correct materials and tools, contractors and DIY enthusiasts alike can ensure a durable and professional-looking finish. Taking the time to understand and apply proper fastening techniques will pay off in the long run with a beautiful, long-lasting ceiling.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024