Feb . 17, 2025 22:10

Back to list

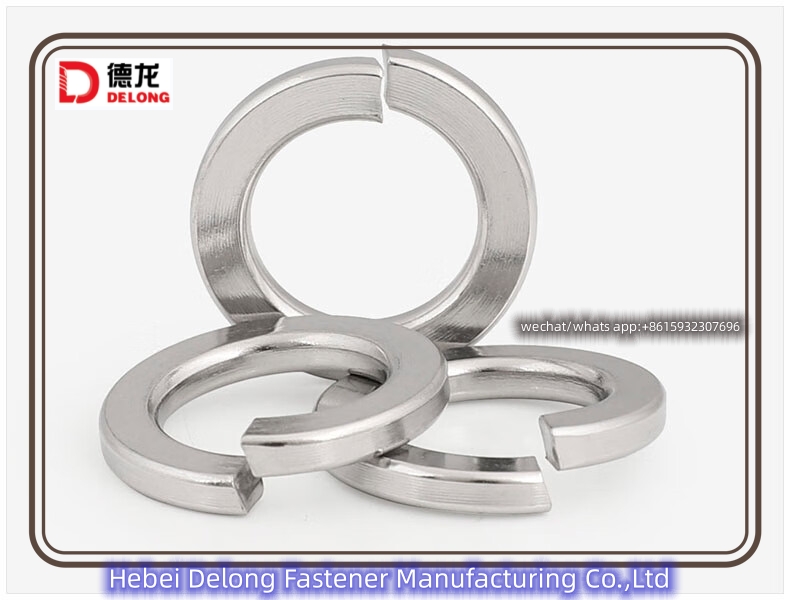

din125 plain washer flat washer

Mastering the nuances of choosing the correct M5 flat washer can significantly impact the functionality and reliability of mechanical assemblies. M5 flat washers, though often overlooked, play a crucial role in distributing the load of threaded fasteners such as bolts and screws, preventing damage under stress. Here, we delve into the specifics of M5 flat washers through expert insights, practical applications, and authoritative advice, focusing on ensuring trust and reliability in their use.

Experts in mechanical design and maintenance stress the importance of applying torque accurately when using M5 flat washers. Over-tightening can compress the washer beyond its yield point, leading to material failure, while under-tightening may cause instability in the fastening system, undermining its effectiveness. Therefore, using calibrated torque wrenches to control pressure is recommended to maintain structural integrity and performance. Additionally, washers should be examined periodically as part of a routine maintenance schedule. Even the most robust materials can succumb to strain over time, especially under fluctuating environmental conditions. Regular inspections can identify early signs of wear, corrosion, or deformation, allowing for timely replacements before they jeopardize the entire assembly. In conclusion, the M5 flat washer, though small, is indispensable in its role of securing fasteners effectively. When considering their integration into a project, attention must be paid to material selection, correct sizing, and maintenance protocols. By adhering to these expert guidelines and maintaining an awareness of their functionality and limitations, professionals and hobbyists alike can maximize the performance and longevity of their mechanical systems. Trust in the quality and specifications of M5 flat washers is enhanced through informed decision-making and regular maintenance practices, aligning with the highest standards of engineering reliability and precision.

Experts in mechanical design and maintenance stress the importance of applying torque accurately when using M5 flat washers. Over-tightening can compress the washer beyond its yield point, leading to material failure, while under-tightening may cause instability in the fastening system, undermining its effectiveness. Therefore, using calibrated torque wrenches to control pressure is recommended to maintain structural integrity and performance. Additionally, washers should be examined periodically as part of a routine maintenance schedule. Even the most robust materials can succumb to strain over time, especially under fluctuating environmental conditions. Regular inspections can identify early signs of wear, corrosion, or deformation, allowing for timely replacements before they jeopardize the entire assembly. In conclusion, the M5 flat washer, though small, is indispensable in its role of securing fasteners effectively. When considering their integration into a project, attention must be paid to material selection, correct sizing, and maintenance protocols. By adhering to these expert guidelines and maintaining an awareness of their functionality and limitations, professionals and hobbyists alike can maximize the performance and longevity of their mechanical systems. Trust in the quality and specifications of M5 flat washers is enhanced through informed decision-making and regular maintenance practices, aligning with the highest standards of engineering reliability and precision.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News