hexagon self drilling screw products

Hexagon Self-Drilling Screws A Comprehensive Overview

In the realm of construction and manufacturing, fastening solutions play a pivotal role in ensuring structural integrity and durability. Among various fastening options, hexagon self-drilling screws have emerged as a popular choice for both professional tradespeople and DIY enthusiasts. This article explores the features, advantages, and applications of hexagon self-drilling screws, providing a comprehensive understanding of their significance in modern construction practices.

What Are Hexagon Self-Drilling Screws?

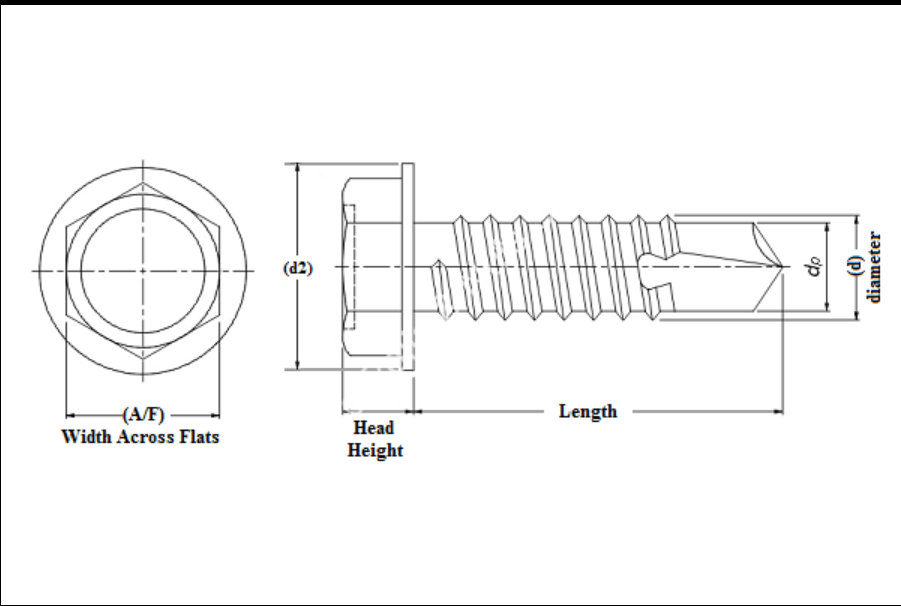

Hexagon self-drilling screws, also known as Tek screws, are specialized fasteners designed with a hexagonal head and a drill point tip. This unique design allows them to penetrate materials without the need for a pre-drilled hole. The self-drilling capability streamlines the fastening process, making it more efficient by reducing labor time and material costs.

Typically made from high-quality steel, these screws are often coated for increased corrosion resistance, making them suitable for various environments, including outdoor applications. Their robust design ensures that they can withstand significant loads, making them ideal for both light and heavy-duty applications.

Advantages of Hexagon Self-Drilling Screws

1. Ease of Installation One of the most significant advantages of hexagon self-drilling screws is their ease of installation. The integrated drill tip allows for quick penetration into various materials, including metal, wood, and plastic. This eliminates the need for pre-drilling, saving time and effort during the assembly process.

2. Increased Speed In fast-paced construction environments, speed is critical. Hexagon self-drilling screws are engineered for rapid installation, allowing workers to complete projects in a timely manner. The use of power tools further enhances this efficiency, enabling contractors to cover more ground with less manpower.

hexagon self drilling screw products

3. Versatility These screws can be used in a wide range of applications, from roofing and siding to steel framing and manufacturing. Their versatility makes them a go-to choice for many industries, including automotive, HVAC, and construction.

4. Strong Hold The hexagonal head design provides a larger surface area for applying torque, which results in a stronger grip. This feature is particularly beneficial in high-stress applications where the integrity of the joint is paramount.

5. Corrosion Resistance Many hexagon self-drilling screws come with specialized coatings that protect against rust and corrosion. This durability extends the lifespan of the fasteners and ensures ongoing performance, even in challenging environments.

Applications of Hexagon Self-Drilling Screws

Hexagon self-drilling screws find applications across various sectors. In construction, they are widely used for attaching roofing sheets, securing metal panels, and installing siding. In manufacturing, these screws can fasten components in machinery and structural frameworks. Moreover, their reliability makes them suitable for automotive and aerospace industries, where safety and strength are crucial.

Conclusion

In summary, hexagon self-drilling screws represent a vital component of modern fastening solutions. Their unique features, such as self-drilling capabilities, ease of installation, and corrosion resistance, make them an indispensable choice for a wide range of applications. As industries continue to evolve, these screws will undoubtedly remain at the forefront of fastening technology, providing efficiency and reliability in construction and manufacturing endeavors. Whether for professional use or DIY projects, hexagon self-drilling screws are a sound investment, ensuring long-lasting and robust structural integrity.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024