Top Manufacturers of Flat Head Self-Drilling Screws for Various Applications

Understanding Flat Head Self-Drilling Screws A Guide for Manufacturers

In the ever-evolving world of construction and manufacturing, the need for reliable and efficient fastening solutions has led to the innovation of various kinds of screws. Among these, flat head self-drilling screws stand out due to their unique design and versatility. This article aims to offer insights into the significance of flat head self-drilling screws, their manufacturing process, and what to consider when selecting a manufacturer.

What Are Flat Head Self-Drilling Screws?

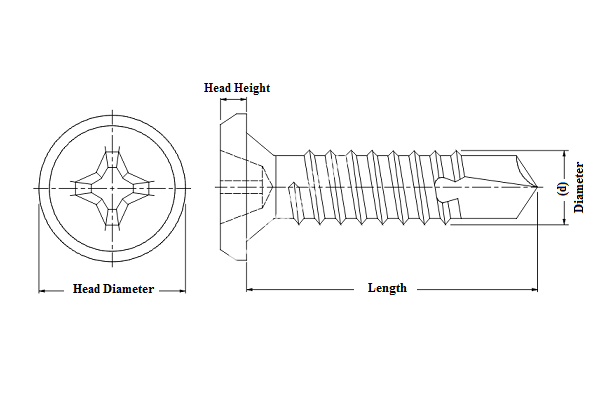

Flat head self-drilling screws are specialized fasteners that eliminate the need for pre-drilling. The flat head design allows these screws to sit flush with the surface of the material, which is vital for aesthetics and functionality in numerous applications. Self-drilling screws feature a sharp point and drill-like threads that allow them to create their own hole as they are driven into the material, making installation quicker and more efficient.

These screws are commonly used in metal-to-metal and metal-to-wood applications, making them suitable for various industries, including construction, HVAC systems, and automotive manufacturing.

Key Features and Benefits

1. Time Efficiency The self-drilling capability reduces installation time since there’s no need for a separate drilling step. This characteristic is particularly beneficial in large-scale projects where time is money.

2. Cost-Effectiveness By eliminating the need for pre-drilling tools and labor, flat head self-drilling screws can significantly reduce labor costs. Additionally, they often require fewer materials overall, contributing to cost savings.

3. Versatility These screws can be used on a variety of materials, including steel, aluminum, and wood, making them a versatile choice for different applications. Their design allows them to handle various environmental conditions and resist corrosion when coated appropriately.

4. Improved Aesthetics The flat head design allows the screw to sit flush with the surface, preventing protrusions that could pose hazards or mar the visual appeal of a finished project.

5. Enhanced Strength The threading and sharp tip improve the screw’s grip, leading to a more secure fastening than traditional screws.

Manufacturing Process

The production of flat head self-drilling screws involves several steps, including

1. Material Selection High-quality materials such as stainless steel, carbon steel, or coated metals are chosen based on the application requirements.

flat head self drilling screw manufacturers

2. Cold Heading The manufacturing process begins with cold heading, where the material is shaped into the desired screw head and body using high-pressure machinery.

3. Thread Rolling The next step involves rolling threads onto the screw body. This process enhances the strength and resilience of the screw and ensures a precise fit.

4. Drilling Process The self-drilling point is crafted, often through precision machining, ensuring that it maintains sharpness and accuracy for effective self-drilling capabilities.

5. Coating and Finishing Finally, screws may receive various coatings for enhanced corrosion resistance and aesthetic purposes. Options may include zinc plating, anodizing, or other protective finishes.

Choosing a Reliable Manufacturer

When seeking a manufacturer for flat head self-drilling screws, several factors should be considered

1. Quality Standards Ensure the manufacturer adheres to strict quality control measures and standards such as ISO certifications. This ensures high-quality production and reliability.

2. Customization Many projects require specific dimensions or coatings. A manufacturer that offers customization options can cater to unique requirements, providing tailored solutions.

3. Reputation Research the manufacturer’s reputation within the industry. Customer reviews and testimonials can provide insight into their reliability and the quality of their products.

4. Technical Support A good manufacturer should provide technical support and expertise, helping clients choose the right products for their applications.

5. Sustainability Practices In today’s market, many companies prioritize sustainability. Considering manufacturers that utilize eco-friendly practices in their production processes can be beneficial for environmentally conscious projects.

Conclusion

Flat head self-drilling screws are paramount in modern construction and manufacturing due to their efficiency, versatility, and aesthetic appeal. Understanding their features and the manufacturing process can help businesses make informed decisions when sourcing these essential fasteners. By choosing a reputable manufacturer that prioritizes quality and customer needs, companies can enhance their projects' overall effectiveness and performance.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024