Recommended Drill Sizes for 14 Gauge Self-Tapping Screws by Manufacturer

Understanding Drill Sizes for 14 Gauge Self-Tapping Screws

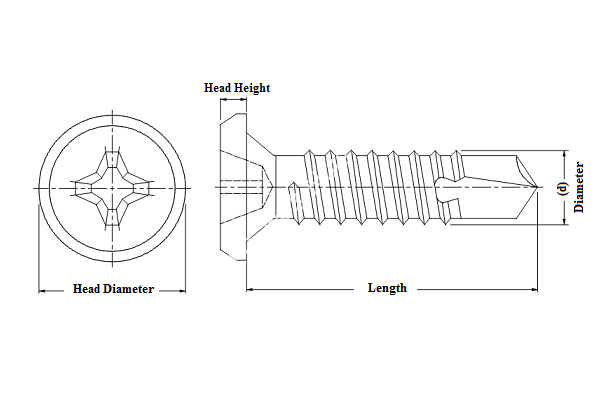

When it comes to woodworking and metal fabrication, self-tapping screws play a critical role in creating secure and permanent connections. The 14 gauge self-tapping screw is especially popular due to its strength and versatility. However, the effectiveness of these screws largely depends on the correct drill size used during installation. In this article, we will explore the importance of selecting the right drill size for 14 gauge self-tapping screws, the factors that influence this selection, and some practical tips for achieving the best results.

What are Self-Tapping Screws?

Self-tapping screws are designed to cut their own thread as they are driven into materials, making them incredibly useful for fastening without the need for pre-drilled holes in many applications. These screws come in various gauges, with 14 gauge being a common choice for tasks that require robust fastening, such as in construction and automotive applications.

Importance of Drill Size

Selecting the proper drill size for a self-tapping screw is crucial for several reasons

1. Maintains Integrity of Materials Using the correct drill size prevents undue stress on the materials being fastened. If the hole is too large, the screw will not have adequate grip, leading to a weakened joint. Conversely, if the hole is too small, it may cause the material to fracture, particularly in brittle substances.

2. Ensures Effective Thread Engagement The purpose of a self-tapping screw is to engage with the material’s threads. A correctly sized hole allows the screw to tap into it effectively, ensuring a strong hold. The threads of the screw must be able to form a secure connection with the material, which is only possible if the drill size is appropriate.

3. Prevents Material Damage An incorrect drill size can lead to splitting or cracking in wood and deformation in metal. This not only compromises the integrity of the joint but can also lead to costly repairs or replacements.

Determining the Right Drill Size

drill size for 14 self tapping screw manufacturer

When working with 14 gauge self-tapping screws, it’s important to consult the manufacturer's specifications, which often provide a recommended drill size for their specific screws. However, there are general guidelines that can be followed

1. Pilot Holes for Metal For metal applications, it is typically recommended to use a drill bit that is slightly smaller than the root diameter of the screw. This ensures that the self-tapping action is effective. For 14 gauge screws, a 7/64 or 5/32 drill bit is often suitable, but checking the manufacturer's specifications is advisable.

2. Wood Applications When driving self-tapping screws into wood, you may need to drill a pilot hole that matches the diameter of the screw’s major diameter. A drill bit size of 3/16 is often used for 14 gauge screws in wood. This allows the threads to cut into the wood fibers efficiently without causing the material to split.

3. Material Considerations The type of material being used affects the drill size as well. Softer woods may require a larger pilot hole to prevent splitting, while harder woods may allow for a smaller hole.

Practical Tips for Installation

- Testing Before final installation, it is wise to test drill on a scrap piece of the same material. This allows you to confirm the accuracy of the drill size and the effectiveness of the screw. - Use Lubrication If you are working with metal, applying a bit of lubricant to the screw can help it cut through the material more easily, ensuring a better fit and reducing wear on the screw.

- Correct Drill Speed Using the right drill speed can also influence the outcome. For metal, a slower speed is usually better, while faster speeds may be suitable for wood.

Conclusion

Selecting the right drill size for 14 gauge self-tapping screws is essential for achieving strong, reliable joints in various applications. By considering the type of material, following manufacturers’ recommendations, and utilizing practical installation tips, you can ensure a successful fastening process. This attention to detail not only enhances the performance of the screws but also extends the life of the materials being joined, making it a critical step in any project involving self-tapping screws.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024