Sizes of Self-Tapping Sheet Metal Screws Made in China

Understanding China Self-Tapping Sheet Metal Screw Sizes

Self-tapping screws are essential fasteners in various applications, particularly in sheet metal construction and assembly. They are designed to create their own hole while being driven into materials, which makes them ideal for securing metal sheets in a range of industries, from automotive to construction. In this article, we’ll explore the dimensions, types, and applications of self-tapping sheet metal screws manufactured in China.

What Are Self-Tapping Screws?

Self-tapping screws are a specific category of screws that can tap their own threads into a material as they are being driven in. This ability eliminates the need for pre-drilled holes in many materials, making them a convenient option for quick assembly and efficiency. In the case of sheet metal, these screws are adept at creating secure connections that can withstand vibration and temperature fluctuations.

Common Sizes of Self-Tapping Screws

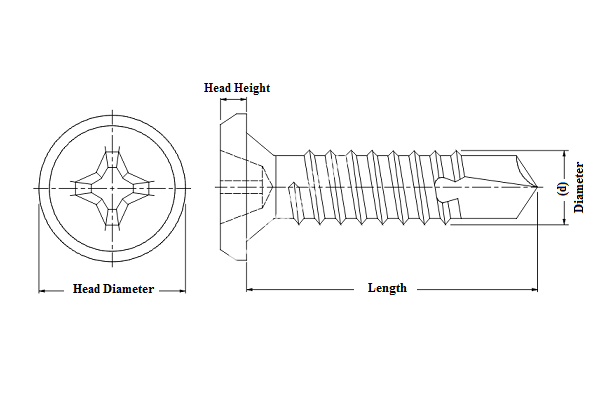

The sizes of self-tapping sheet metal screws can vary significantly based on their intended application. They are typically measured by their diameter and length, which can be listed in metric (millimeters) or imperial (inch) units. Common diameters range from 4 (2.8 mm) to 14 (6.3 mm), while lengths can vary from 1/2 inch (12.7 mm) to 2 inches (50.8 mm) or more.

1. Diameter Sizes - 4 Commonly used for small projects and light-duty applications, ideal for thin materials. - 8 A versatile screw size that can be used in various applications, providing moderate strength. - 10 Suitable for medium-duty applications; often used in automotive and appliance assembly. - 14 This larger diameter screw is designed for heavy-duty applications where additional holding power is necessary.

china self tapping sheet metal screw sizes

Types of Self-Tapping Screws

Self-tapping screws come in various designs, each suited for specific materials and functionalities

- Type A This is a general-purpose screw designed for thin metal sheets, delivering a good balance between performance and ease of use. - Type B Known for its blunt end, this screw is often used in soft materials as it does not require a pre-drilled hole. - Type C These screws are made for thicker materials and have sharper threads that help achieve greater grip. - Hex Head Screws These have a hexagonal head that allows for easy use with a wrench, providing a different method of torque application.

Application in Various Industries

Self-tapping sheet metal screws manufactured in China are used across numerous sectors. In the automotive industry, they secure body panels and components, offering reliability and strength. In construction, self-tapping screws are commonly used for attaching metal roofing, siding, and structural components due to their durability against weather elements.

Additionally, in the appliance industry, self-tapping screws are favored for their ease of assembly and disassembly, allowing manufacturers to create products that are not only sturdy but also easy to repair or recycle.

Conclusion

Chinese manufacturers produce a wide range of self-tapping sheet metal screws that cater to various needs across industries. By understanding the different sizes, types, and applications, users can make informed decisions about which fasteners to use for their specific requirements. The versatility and convenience of self-tapping screws continue to make them a staple in both commercial and residential projects, reflecting their integral role in modern engineering and construction.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024