जनवरी . 09, 2025 12:23

Back to list

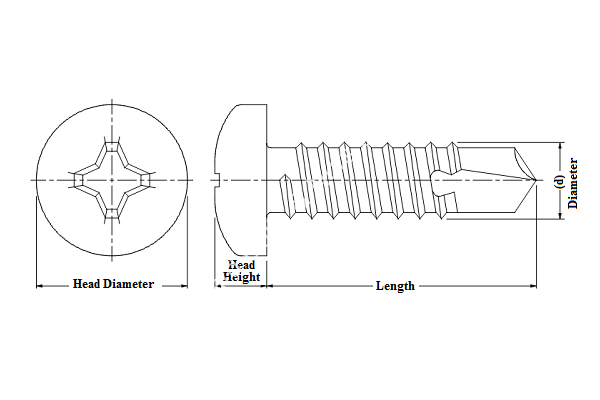

china screw

Exploring the Quality and Applications of China Screws A Personal Journey

The authoritative presence of China screws in the global market is backed by their compliance with international standards, including ISO, DIN, and JIS. Moreover, Chinese manufacturers are frequently engaged in cooperative developments with international firms, fostering innovation and setting benchmarks in the fastener industry. I remember a vivid illustration of this during a conference where a Chinese manufacturer demonstrated a new alloy blend in their screws, enhancing durability without compromising on weight—a game-changer for the heavy machinery sector. The trustworthiness of China screws is inherently linked to this dedication to quality and compliance. While price competitiveness is a well-known advantage, assurances come from verifiable certifications and rigorous testing protocols. During procurement processes, diving into documents like material test reports and quality audit trails can provide substantial peace of mind. My contracts with suppliers invariably include stipulations for such transparency, which they readily accommodate—indicative of their commitment to maintaining trust. In conclusion, the journey from skepticism to appreciation concerning China screws reflects the robust growth in their manufacturing domain. By investing in technology, expertise, and compliance, Chinese manufacturers have positioned themselves as reliable and authoritative participants in the global market. For practitioners seeking dependable and versatile fastening solutions, investigating the offerings of China screws, backed by authentic experiences and expert testimonies, might just offer the quality assurance needed for ambitious engineering projects.

The authoritative presence of China screws in the global market is backed by their compliance with international standards, including ISO, DIN, and JIS. Moreover, Chinese manufacturers are frequently engaged in cooperative developments with international firms, fostering innovation and setting benchmarks in the fastener industry. I remember a vivid illustration of this during a conference where a Chinese manufacturer demonstrated a new alloy blend in their screws, enhancing durability without compromising on weight—a game-changer for the heavy machinery sector. The trustworthiness of China screws is inherently linked to this dedication to quality and compliance. While price competitiveness is a well-known advantage, assurances come from verifiable certifications and rigorous testing protocols. During procurement processes, diving into documents like material test reports and quality audit trails can provide substantial peace of mind. My contracts with suppliers invariably include stipulations for such transparency, which they readily accommodate—indicative of their commitment to maintaining trust. In conclusion, the journey from skepticism to appreciation concerning China screws reflects the robust growth in their manufacturing domain. By investing in technology, expertise, and compliance, Chinese manufacturers have positioned themselves as reliable and authoritative participants in the global market. For practitioners seeking dependable and versatile fastening solutions, investigating the offerings of China screws, backed by authentic experiences and expert testimonies, might just offer the quality assurance needed for ambitious engineering projects.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News