Self Tapping Screw Sizes and Specifications for 2014 Models

Understanding Self-Tapping Screw Dimensions The 2014 Buyer's Guide

When it comes to fastening applications, self-tapping screws are a popular solution due to their ability to create their own threads while being driven into materials. This article focuses on the dimensions and specifications that are crucial for selecting the right self-tapping screws, especially those relevant to the year 2014. Whether you are a DIY enthusiast or a professional tradesperson, knowing these dimensions can significantly impact your project's success.

What Are Self-Tapping Screws?

Self-tapping screws are specialized fasteners designed to tap their own threaded holes as they are driven into materials. This makes them ideal for use in various materials, including metal, wood, and plastic. They eliminate the need for pre-drilling, which saves both time and labor costs. Given their efficiency, self-tapping screws are widely used in construction, manufacturing, and home improvement projects.

Key Dimensions of Self-Tapping Screws

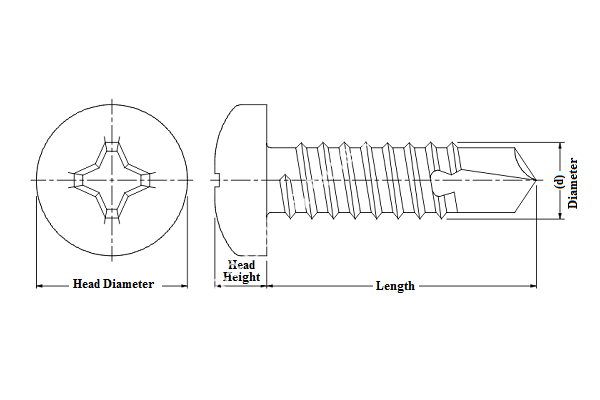

1. Diameter The diameter of a self-tapping screw is one of the most critical dimensions. It typically ranges from 0 (1.1 mm) to 14 (6.35 mm) for smaller screws, and larger sizes may go up to 1/2 inch or more for heavier applications. The diameter affects the screw's strength and load-bearing capacity.

2. Length The length of the screw is another vital consideration. It usually varies from 1/4 inch to several inches depending on the application. When choosing the length, it’s important to account for the thickness of the materials being fastened to ensure adequate penetration and holding power.

3. Thread Type Self-tapping screws come with various thread configurations, including coarse and fine threads. Coarse threads (typically used in softer materials like wood) provide quicker engagement, whereas fine threads (usually for metal applications) offer better strength and resistance to stripping.

buy 14 self tapping screw dimensions

4. Head Style The head style can affect both the aesthetic and functional aspects of a project. Common styles include pan head, flat head, and hex head, each designed for specific applications and offering different drive configurations (like Phillips, slotted, or torx). The choice of head style will depend on the tool available and the intended use.

5. Point Type The point of a self-tapping screw is crucial, as it determines how effectively it can penetrate the material. Common point types include sharp points for wood and drill points for metals. The design of the point can also impact how cleanly a screw penetrates without splitting the material.

6. Material Composition The material of the self-tapping screw varies widely and plays a significant role in its performance. Common materials include stainless steel, carbon steel, and zinc-plated steel. Each material offers different characteristics regarding corrosion resistance, strength, and suitability for specific environments.

Choosing the Right Self-Tapping Screw

When selecting self-tapping screws, it is essential to consider the material of both the screw and the substrate. For instance, if you are fastening steel components, you will want a screw made from a strong, corrosion-resistant material such as stainless steel. Conversely, for wooden applications, a coated carbon steel screw may be sufficient.

Additionally, always pay attention to the manufacturer's specifications for dimensions and weight ratings. Some projects may require screws with specific load-bearing capabilities, so it's crucial to ensure that the screws you select align with those requirements.

Conclusion

In conclusion, understanding the dimensions and specifications of self-tapping screws is vital for achieving optimal results in various fastening applications. The year 2014 saw a variety of advancements in screw design and manufacturing processes, contributing to increased efficiency and versatility. By paying close attention to diameter, length, thread type, head style, point type, and material composition, you can make informed decisions that enhance the quality and durability of your projects. Whether you’re assembling furniture, constructing a deck, or engaging in industrial applications, the right self-tapping screw will ensure the strength and longevity of your work.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024