Understanding the Diameter of 8% Drywall Screws in Manufacturing and Applications

Understanding the Diameter of 8% Drywall Screws A Factory Perspective

In the world of construction and interior design, the quality of materials used plays a critical role in ensuring the durability and longevity of structures. Among these materials, drywall screws are essential for securing drywall sheets to framing. One specific type is the 8% drywall screw, which is noteworthy not just for its intended application but also for its dimensions and the manufacturing process involved in its production.

What Are 8% Drywall Screws?

The term “8% drywall screw” refers to the percentage of a specific measurement related to the screw’s diameter, usually indicating a certain size range that is optimal for various applications. These screws are typically coated to enhance resistance against corrosion and facilitate easier driving. They are designed to be used with drywall materials of various thicknesses and are an integral part of any drywall installation project.

Importance of Screw Diameter

When it comes to drywall screws, the diameter is a critical factor that influences the screw’s holding power. A screw that is too thin may not provide adequate strength, while a screw that is too thick can split the drywall or other materials. The typical diameter for drywall screws generally ranges from 6 to 10, with the 8 size being a popular choice due to its balanced strength and handling characteristics.

Manufacturing Process in a Factory Setting

The process of manufacturing 8% drywall screws begins with selecting high-quality raw materials, primarily steel, which is then treated for enhanced durability. Here’s a brief overview of how these screws are made

#8 drywall screw diameter factory

2. Forming and Shaping Steel wire is cut and shaped under high pressure to form the head and shank of the screw. This is a key step as it determines the screw’s final dimensions, including its diameter.

3. Threading Next, the screw is threaded, which is crucial for its grip. This process involves precision machinery that ensures the threads are uniform and precise, allowing for better installation and stability.

4. Coating After threading, the screws are coated with a protective material, often zinc or another form of plating. This serves to prevent rust and corrosion, extending the screws’ usability in various environments.

5. Quality Control Finally, rigorous quality control checks are implemented to ensure that each screw meets the specified diameter and overall quality standards. This includes testing for strength, durability, and corrosion resistance.

Applications of 8% Drywall Screws

The versatility of 8% drywall screws allows them to be used in various applications, primarily in drywall installations but also in securing other materials like wood and plastic. Contractors appreciate the reliability of these screws, as they ensure that drywall panels are firmly attached to the frame, which is vital for both structural integrity and the overall finish of the wall.

Conclusion

Understanding the diameter and properties of 8% drywall screws is essential for anyone involved in construction, renovation, or DIY projects. From the manufacturing process in factories to real-world applications, these screws play a pivotal role in ensuring stability and durability. By selecting the right type of screw and comprehending the importance of its specifications, builders and homeowners alike can achieve high-quality installations that stand the test of time. Whether you’re a seasoned contractor or a first-time DIYer, knowledge of tools like drywall screws is invaluable in achieving successful project outcomes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

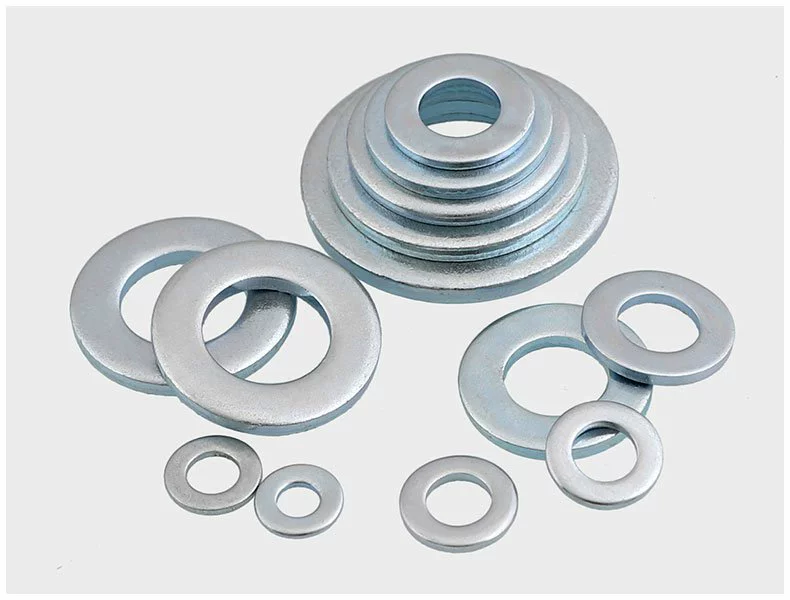

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024