Dimensions and Specifications for 6% Self-Tapping Screws from Leading Manufacturers

Understanding 6% Self Tapping Screw Dimensions A Comprehensive Overview

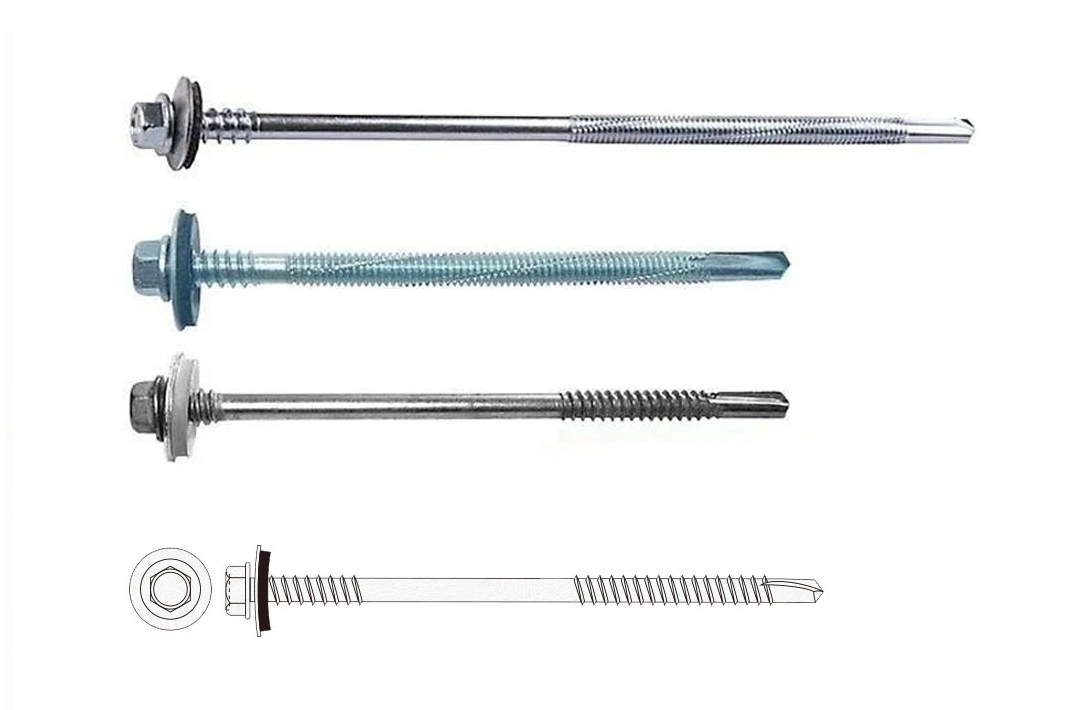

Self-tapping screws are an essential fastener in various construction and manufacturing applications. Among the myriad options available, the 6% self-tapping screw stands out due to its unique design and versatility. In this article, we will delve into the dimensions and features of 6% self-tapping screws, exploring their applications and advantages in various industries.

What Are Self-Tapping Screws?

Self-tapping screws are designed to create their own threads as they are driven into material. This eliminates the need for pre-drilled holes, allowing for quicker and more efficient assembly. The 6% designation refers to the specific geometry and design features of the screw, which significantly enhance its performance in specific applications.

Common Dimensions of 6% Self Tapping Screws

The dimensions of self-tapping screws can vary based on their intended use, but they typically encompass the following key parameters

1. Diameter The diameter of a 6% self-tapping screw is commonly between 8 and 10, which corresponds to approximately 4 mm to 5 mm. The diameter is a crucial factor, as it determines the screw's strength and its ability to handle various materials.

2. Length The length of self-tapping screws usually ranges from 0.5 inches to 2 inches (approximately 12 mm to 50 mm). Shorter screws are ideal for thinner materials, while longer screws are required for thicker materials or applications where a stronger grip is needed.

3. Thread Count Tightening and gripping performance significantly depend on the thread count. A 6% self-tapping screw typically features finer threads that allow for better engagement with the substrate, enhancing its overall performance.

4. Head Shape The head shape can vary, with common types being flat, pan, and hex heads. Each shape serves different purposes, with flat heads being suitable for flush applications and hex heads providing a stronger grip for higher torque applications.

5. Material and Coating The screw material (commonly zinc-plated steel, stainless steel, or plastic) and the type of coating (such as galvanization) also play significant roles in determining the best fit for specific projects. Coated screws are used to increase corrosion resistance, particularly in outdoor or high-moisture environments.

6 self tapping screw dimensions company

Applications of 6% Self-Tapping Screws

Due to their versatile nature, 6% self-tapping screws are widely used in various applications

- Construction Ideal for securing metal and wood frames, drywall installation, and roofing applications. - Automotive Used for fastening components within vehicles, including panels and mechanical parts. - Electronics Perfect for assembling electronic devices where lightweight and secure connections are essential. - Furniture Manufacturing Commonly found in ready-to-assemble furniture, where quick assembly times are critical.

Advantages of Using 6% Self-Tapping Screws

1. Efficiency The ability to create their own threads eliminates labor-intensive pre-drilling, making assembly quicker and more efficient. 2. Cost-Effectiveness The reduction in assembly time translates into lower labor costs, making self-tapping screws a cost-effective solution for many projects.

3. Versatility Suitable for a wide range of materials, different head styles, and finishes, these screws provide flexibility in design and application.

4. Strength Due to their design, 6% self-tapping screws can achieve sufficient grip without compromising the integrity of the materials being fastened.

5. Availability With the high demand for self-tapping screws, suppliers typically stock a range of dimensions, making it easier for manufacturers and builders to find suitable options for their specific needs.

Conclusion

In summary, 6% self-tapping screws are a vital component in many construction and manufacturing sectors. Understanding their dimensions, applications, and advantages can help professionals make informed decisions that enhance efficiency and effectiveness in their projects. Whether for simple tasks at home or complex industrial applications, these fasteners continue to play a crucial role in connecting and securing various materials.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024