Spring Tool Manufacturing for Washer Gaskets in Various Factories

The Role of Washer Gaskets and Springs in Industrial Applications

In the world of manufacturing and mechanical engineering, the significance of components like washer gaskets and springs cannot be understated. These seemingly simple parts play a critical role in ensuring the efficiency and longevity of machinery. This article explores the importance of washer gaskets and springs, the various types available, and the innovations in this field, particularly focusing on industrial factories that specialize in these components.

Understanding Washer Gaskets and Springs

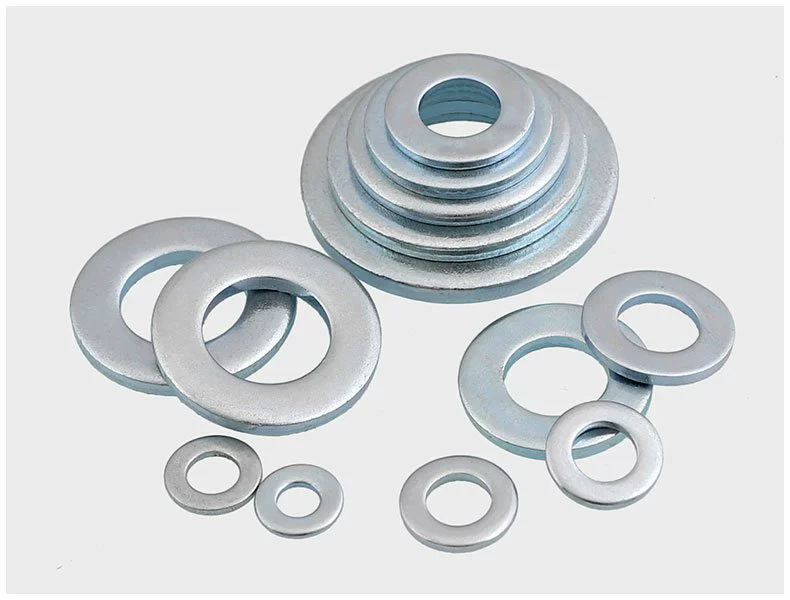

Washer gaskets are crucial sealing components used to prevent leaks in various applications, including plumbing, automotive, and manufacturing processes. These gaskets create a tight seal between different surfaces and are designed to withstand various pressures, temperatures, and environmental conditions.

Springs, on the other hand, are mechanical devices used to store energy and release it when needed. They can be found in virtually every machine, from simple devices to complex industrial systems. Springs maintain tension, absorb shock, and provide necessary resistance in numerous applications.

Types of Washer Gaskets

There are numerous types of washer gaskets available, each designed for specific applications

1. Flat Gaskets These are the most common type, made from materials such as rubber, silicone, or metal. They are used in non-moving applications where a flat surface seals against another flat surface.

2. O-Rings These circular gaskets are used in dynamic applications and provide an effective seal in a variety of equipment, including pumps and hydraulic systems.

3. Metal Gaskets Ideal for high-pressure environments, metal gaskets can withstand extreme temperatures and are commonly used in automotive and aerospace industries.

4. Spiral Wound Gaskets These gaskets are particularly suitable for high-temperature and high-pressure applications. They are made up of alternating layers of metal and soft material, ensuring a reliable seal.

Types of Springs

washer gasket spring tool factories

Springs are classified into several categories based on their application and design

1. Compression Springs Designed to resist compressive forces, these springs are commonly used in automotive and industrial applications to absorb shocks.

2. Tension Springs These springs are designed to operate under tension, pulling components together. They are widely used in applications such as appliances and industrial machinery.

3. Torsion Springs Effective for providing rotational force, torsion springs are used in mechanisms like clothespins and various locking devices.

4. Leaf Springs Typically used in vehicles, leaf springs provide support and absorb shock, contributing significantly to ride comfort and stability.

Innovations in Washer Gasket and Spring Manufacturing

As industries evolve, so do the technologies and processes that fabricate these essential components. Factory innovations in washer gasket and spring manufacturing include the use of advanced materials, such as composites and alloys, to enhance durability and performance.

3D printing technologies are also gaining traction in the production of custom gaskets and springs, allowing for rapid prototyping and efficient production cycles. This technology enables manufacturers to create complex shapes and designs that were previously challenging to produce.

Furthermore, automation in factories has led to increased production efficiency. Automated assembly lines can produce these components with high precision, ensuring consistent quality and reduced lead times.

Conclusion

In conclusion, washer gaskets and springs are indispensable components in various industries, providing the reliability and efficiency necessary for modern machinery. The ongoing innovations in manufacturing techniques and materials are paving the way for even more advanced and efficient solutions. As industries continue to grow, the importance of these components will only increase, underscoring the need for specialized factories dedicated to their production. Understanding the different types and applications of washer gaskets and springs not only aids engineers and manufacturers in making informed decisions but also contributes to the overall performance and sustainability of industrial processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024