Understanding Sizes and Specifications of Self-Drilling Sheet Metal Screws for Various Applications

Understanding Self-Drilling Sheet Metal Screw Sizes A Comprehensive Guide

When it comes to construction and manufacturing, self-drilling sheet metal screws are essential components. They provide a reliable means of fastening materials together without the need for pre-drilling holes, significantly saving time and increasing efficiency. However, selecting the right size is crucial for ensuring the structural integrity of your project. This article will discuss the various sizes of self-drilling sheet metal screws, their specifications, and considerations you should keep in mind when choosing the right one for your application.

What Are Self-Drilling Sheet Metal Screws?

Self-drilling screws, also known as Tek screws, are designed with a drill bit-like point that allows them to bore into sheet metal without needing any additional preparation. This characteristic makes them incredibly popular for applications involving metal-to-metal or metal-to-wood connections, such as in roofing, HVAC installations, and various construction projects.

Key Specifications

When evaluating self-drilling sheet metal screws, there are several key specifications to consider

1. Diameter The diameter of a screw is typically given in inches or millimeters. Common sizes for self-drilling screws range from 6 to 14, with each number representing a specific diameter. For example, a 6 screw has a diameter of approximately 0.138 inches, while a 14 screw has a diameter of about 0.197 inches.

2. Length Self-drilling screws come in various lengths, usually from 1/2 inch to 4 inches. The appropriate length will depend on the thickness of the material being fastened. As a general rule, the screw should penetrate at least one thread’s worth into the underlying material to ensure a strong hold.

3. Thread Type There are various thread configurations available, including fine and coarse threads. Fine threads are generally better for thinner materials, while coarse threads provide better grip in thicker materials or when fastening into softer substrates.

4. Point Type The point style of the screw can also affect its performance. Common point types include Type 2 (for use in sheet metal) and Type 3 (for thicker materials). The right point type will depend on the material and the thickness involved.

self drilling sheet metal screw sizes quotes

5. Material and Coating The materials used in manufacturing self-drilling screws can vary, often including stainless steel, carbon steel, and other alloys. Protective coatings, such as zinc plating, are also available to enhance corrosion resistance, making them suitable for outdoor applications.

Choosing the Right Size

When selecting the appropriate size of self-drilling sheet metal screws, consider the following factors

- Material Thickness Choose a screw that is approximately 1.5 times the thickness of the material you are fastening. For example, if you are working with a sheet metal that is 0.05 inches thick, a screw length of approximately 0.075 inches (1.5 times the thickness) would be appropriate.

- Load Requirements For applications that will bear significant weight or stress, opt for larger diameter screws that can provide additional strength.

- Installation Environment If your project is exposed to harsh weather conditions, consider using stainless steel screws or those with anti-corrosion coatings.

- Type of Material When fastening to different materials, such as wood or composite products, ensure that the screw’s thread design and point type are appropriate for the base material.

Conclusion

When choosing self-drilling sheet metal screws, understanding their sizes and specifications is fundamental to ensuring a successful fastening solution. By taking into account the material thickness, load requirements, and installation environment, you can select the appropriate screws that will not only securely hold your materials together but also enhance the durability and longevity of your project. Taking the time to choose the right screw size pays off in the long run, providing peace of mind that your construction will stand the test of time.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

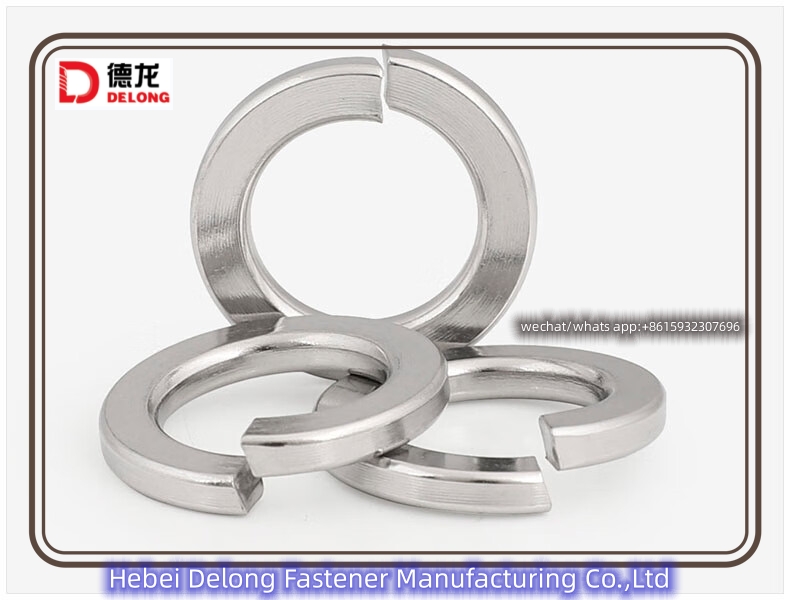

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024