drill size for 14 self tapping screw factory

Understanding Drill Sizes for 14 Self-Tapping Screws

Self-tapping screws are a versatile fastening solution employed in various industries, including construction, automotive, and electronics. They are designed to drill their own hole as they are driven into material, eliminating the need for a pre-drilled pilot hole in many cases. However, selecting the appropriate drill size is crucial to ensure optimal performance and avoid stripping, breaking, or damaging the material being fastened. This article will explore the specific drill sizes recommended for 14 self-tapping screws and offer insights into their selection criteria.

What are Self-Tapping Screws?

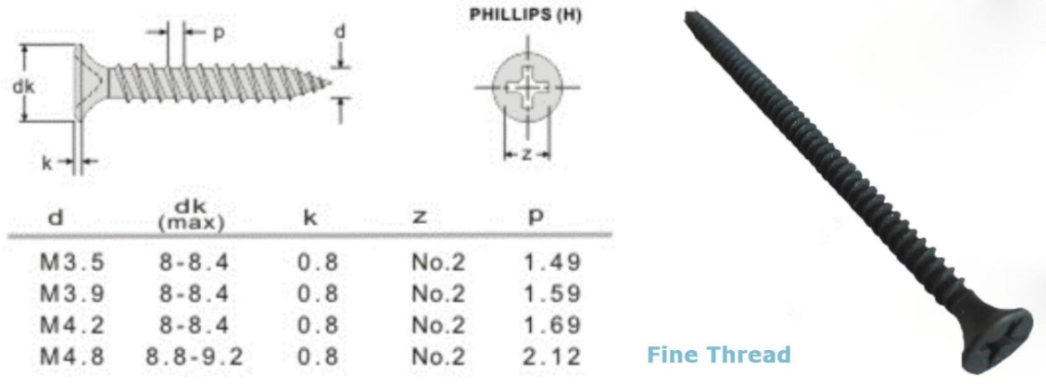

Self-tapping screws are distinctive in that they have sharp threads and points designed to cut into the material. These screws can tap their own threads, allowing for quick and easy installation. They are typically used in materials like wood, metal, and plastics. The design of self-tapping screws makes them an efficient choice for a variety of applications, but the correct drill size is essential to achieving the desired hold and stability.

Importance of Drill Size

Using an appropriate drill size when working with self-tapping screws is vital for several reasons

1. Grip Strength An overly large hole may cause the screw to loosen over time, while a hole that is too small can lead to screw breakage or material damage during installation.

2. Ease of Installation The correct drill size allows the screw to drive in smoothly without excessive force, making the installation process more straightforward.

drill size for 14 self tapping screw factory

Recommended Drill Sizes for 14 Self-Tapping Screws

When referring to self-tapping screws, the size can vary significantly based on the screw's diameter, length, and intended application. For a common 14 self-tapping screw, the following drill sizes can be used

1. Softwood For softwood applications, a drill bit size of approximately 7/64 inches (about 2.78 mm) is often recommended. This size allows the screw to create the necessary threads while maintaining a solid grip.

2. Hardwood In hardwood scenarios, a slightly larger drill bit of around 1/8 inches (about 3.2 mm) may be necessary. Utilizing this size helps prevent splitting by allowing the screw to cut its own path smoothly.

3. Sheet Metal For self-tapping screws in sheet metal, a drill size of 5/32 inches (approximately 3.97 mm) can be beneficial. This size helps the screw penetrate the material effectively while still providing a robust hold.

4. Plastic When working with plastics, a drill bit size of 3/32 inches (about 2.38 mm) is generally suitable. This ensures that the screw can bite into the material without causing damage.

Conclusion

Choosing the correct drill size for 14 self-tapping screws ensures not only the efficacy of the fastening but also the longevity and durability of the materials involved. With various applications ranging from woodworking to automotive assembly, understanding the specific drill sizes for self-tapping screws is critical. Always refer to the screw manufacturer’s guidelines and consider the material being worked on to determine the most suitable drill size. By paying attention to these details, you can achieve a secure and reliable fastening that meets the demands of your specific project.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024