Wafer Head Self-Drilling Screws Data Sheet with 201% Discount Offer

The Advantages and Applications of Wafer Head Self-Drilling Screws

In the world of construction and manufacturing, the importance of choosing the right fasteners cannot be overstated. Fasteners are essential components that hold materials together, and their reliability can significantly affect the integrity of a structure. Among the various types of fasteners available, wafer head self-drilling screws have gained substantial popularity due to their unique design and functional capabilities. This article delves into the characteristics, advantages, and applications of wafer head self-drilling screws, highlighting their significance in various industries.

What Are Wafer Head Self-Drilling Screws?

Wafer head self-drilling screws are specialized fasteners designed to penetrate and secure materials without the need for a pre-drilled hole. The head of these screws is wide and flat, allowing for a larger bearing surface that distributes the load more evenly. This design not only improves the holding power but also reduces the risk of stripping. The drill point on these screws enables them to create their own holes as they are driven into the material, which is particularly beneficial in applications involving metal and wood.

Key Advantages

1. Time Efficiency One of the primary advantages of wafer head self-drilling screws is the time saved during installation. The self-drilling feature eliminates the need for pre-drilling, allowing for quicker fastening. This is especially advantageous in large-scale construction projects where time is a critical factor.

2. Reduced Labor Costs By significantly decreasing the time required for installation, these screws can ultimately lead to reduced labor costs. Fewer labor hours translate into cost savings for contractors and project managers.

3. Versatility Wafer head self-drilling screws can be utilized in a variety of applications, including sheet metal, wood, and plastic. They are commonly used in the assembly of metal roofing, siding, and various other structures. Their adaptability makes them an appealing choice for contractors working on diverse projects.

4. Enhanced Holding Power Thanks to their wide head design, these screws provide excellent grip and minimize the chance of loosening over time. This is particularly important in applications that experience vibrations or dynamic loads.

discount 1 1 4 wafer head self drilling screw data sheet

5. Corrosion Resistance Many wafer head self-drilling screws are coated or manufactured with corrosion-resistant materials, making them suitable for outdoor use or in environments exposed to moisture. This characteristic extends the lifespan of the fastener and enhances the durability of the structure.

Applications

1. Metal Construction Wafer head self-drilling screws are widely used in metal construction, particularly in the installation of metal roofing and siding. Their ability to drill directly into metal without pre-drilling makes them ideal for these applications.

2. HVAC Systems These screws are often used to assemble components in HVAC systems, where a tight and secure fit is crucial to prevent leaks and ensure efficiency.

3. Garage Doors The installation of garage doors often requires durable fasteners that can withstand the mechanical stress. Wafer head self-drilling screws provide the necessary strength and stability.

4. Commercial Signage In the signage industry, the need for a strong bond between materials and supports is critical. Wafer head self-drilling screws are frequently employed to secure signs to metal structures.

5. Wood Applications While primarily used for metal, these screws can also be effective when working with wood, particularly in cases where a quick assembly is needed without the hassle of pre-drilling.

Conclusion

Wafer head self-drilling screws represent a remarkable advancement in fastening technology. Their efficiency, strength, and versatility make them invaluable in a wide range of industries, especially where speed and reliability are paramount. As construction methods continue to evolve, the demand for innovative fastening solutions like wafer head self-drilling screws is likely to grow. For contractors, builders, and manufacturers, investing in quality fasteners is essential to ensure the longevity and safety of their projects. Understanding the benefits and applications of wafer head self-drilling screws is a vital step towards making informed choices in materials and methods, ultimately leading to successful outcomes in construction and manufacturing endeavors.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

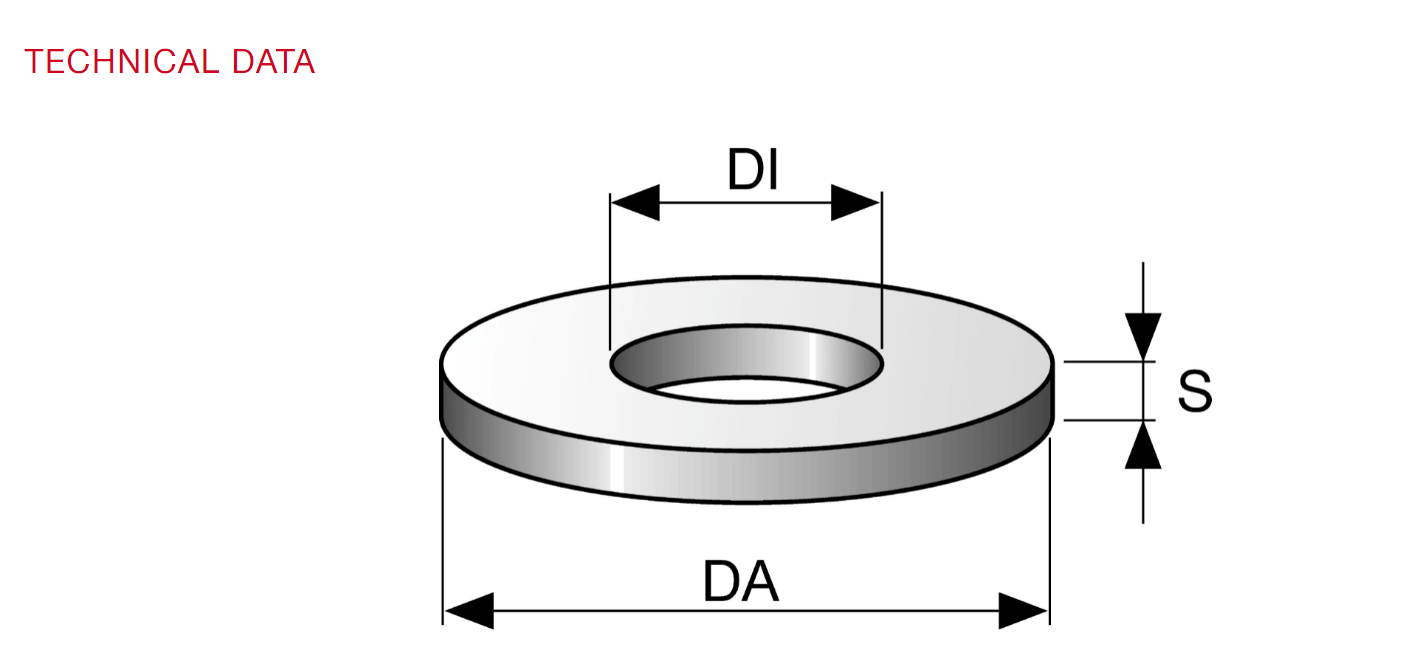

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024