aluminum self tapping screw suppliers

Understanding Aluminum Self-Tapping Screws and Their Suppliers

In the world of fasteners, aluminum self-tapping screws have carved out a vital niche. These specialized screws not only serve as essential components for assembling a wide variety of materials but also bring unique advantages to many applications. As industries continue to evolve and seek more effective fastening solutions, understanding the significance of aluminum self-tapping screws and their suppliers becomes crucial.

The Basics of Aluminum Self-Tapping Screws

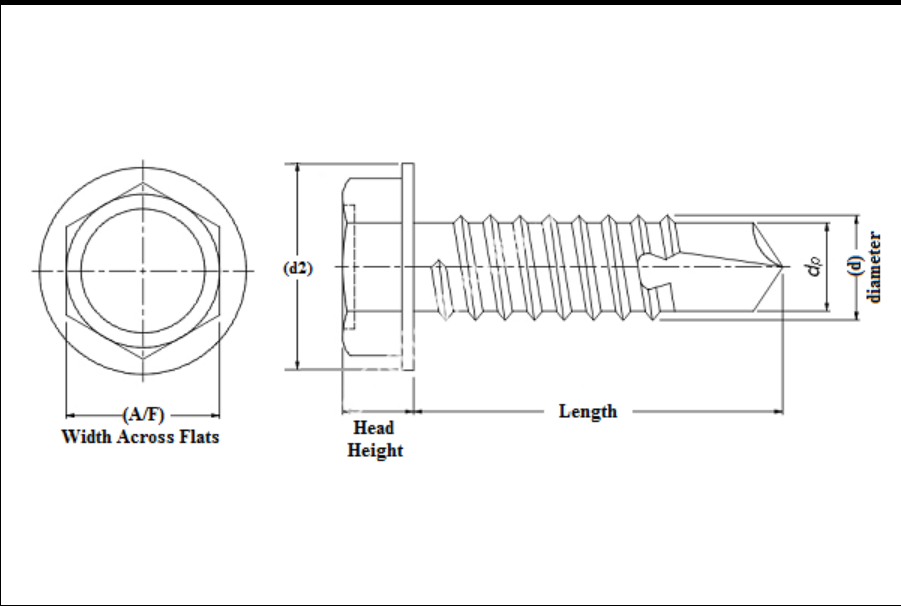

Self-tapping screws are designed to create their own hole as they are driven into materials, eliminating the need for pre-drilling. This feature significantly enhances efficiency during assembly, reducing the time and labor required in construction and manufacturing processes. Aluminum, being lightweight and resistant to corrosion, makes these screws particularly valuable in environments where traditional steel fasteners may succumb to rust or weight issues.

Aluminum self-tapping screws come in various sizes and thread patterns, tailored to meet specific requirements. They are predominantly used in applications involving aluminum, plastics, and thin metal sheets. Their ability to tap into softer materials while maintaining a strong grip is a significant advantage, making them indispensable in automotive, aerospace, electronics, and furniture manufacturing.

Advantages of Aluminum Screws

1. Corrosion Resistance Aluminum naturally forms a protective oxide layer which resists corrosion, making these screws ideal for outdoor applications or environments with high humidity.

2. Lightweight The lightness of aluminum contributes to weight savings in products where every gram counts, such as in aerospace and automotive designs.

4. Electrical Conductivity In certain applications, aluminum screws can serve dual purposes by providing both mechanical fastening and electrical continuity.

Given these advantages, the demand for aluminum self-tapping screws has grown, prompting a surge in suppliers focusing on this specific type of fastener.

aluminum self tapping screw suppliers

Finding Reliable Suppliers

When it comes to sourcing aluminum self-tapping screws, businesses need to partner with reliable suppliers who can offer high-quality products that meet industry standards. Here are several factors to consider when choosing a supplier

1. Reputation and Experience It is essential to select suppliers with a proven track record in the industry. A reputable supplier is likely to provide consistent quality and good customer service.

2. Product Range Suppliers that offer a wide range of sizes, thread patterns, and coatings can provide more versatile solutions and adapt to specific project requirements.

3. Customization Options Some projects may require unique specifications. Suppliers who offer customization options for their fasteners can be particularly beneficial.

4. Quality Assurance Check if the supplier conducts rigorous quality control checks. Certifications such as ISO 9001 can be indicators of high-quality manufacturing practices.

5. Pricing and Availability Competitive pricing without compromising quality is essential for budget-conscious projects. Additionally, quick fulfillment can be crucial in maintaining project timelines.

Conclusion

Aluminum self-tapping screws represent a compelling fastening solution for numerous applications across various industries. Their lightweight, corrosion-resistant properties coupled with the convenience of self-tapping make them invaluable. As demand rises, the role of suppliers becomes even more critical. By understanding the advantages of these screws and knowing which factors to consider when selecting a supplier, businesses can ensure they meet their fastening needs effectively.

Through proper selection of quality suppliers, industries can harness the benefits of aluminum self-tapping screws, promoting efficient and durable assemblies in their operations.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024