3/16 Inch Lock Washer Manufacturers and Suppliers for Reliable Hardware Solutions

Exploring the World of 3/16 Inch Lock Washer Factories

In the intricate realm of industrial manufacturing, the lock washer stands out as an essential component that ensures the integrity and stability of various products. Particularly, the 3/16 inch lock washer has gained significant popularity due to its versatile application across numerous industries, ranging from automotive to electronics. This article delves into the fascinating world of 3/16 inch lock washer factories, highlighting their manufacturing processes, quality standards, and global significance.

Understanding Lock Washers

Lock washers are specialized fasteners designed to prevent loosening under vibration or movement. The 3/16 inch lock washer, specifically, is characterized by its diameter, which is perfect for a multitude of fastening applications. These washers are typically made from materials such as steel, stainless steel, or even plastic, depending on the specific requirements of the application. Their design often features ridges or teeth that grip the surface of the fastened material, providing enhanced friction and stability.

The Manufacturing Process

The production of 3/16 inch lock washers involves several intricate steps that ensure uniformity and reliability. It begins with the selection of raw materials, which must adhere to specific industry standards for strength and corrosion resistance. The raw materials are then processed through various stages, including cutting, forming, and heat treatment.

1. Material Selection Factories typically utilize materials like carbon steel and stainless steel, which provide the necessary strength and durability. The choice of material directly affects the performance and longevity of the final product.

2. Pressing Using precision stamping machines, manufacturers cut out circular disks that will eventually become washers. This step requires careful calibration to ensure that each washer meets the specified 3/16 inch measurement.

3. Forming The disks are then subjected to a forming process, which involves creating the distinctive ridges or teeth that characterize lock washers. This process is critical as it impacts the washer's ability to lock in place.

4. Heat Treatment To enhance strength and durability, lock washers often undergo heat treatment. This process increases their resistance to wear and tear, ensuring they can withstand the rigors of various applications.

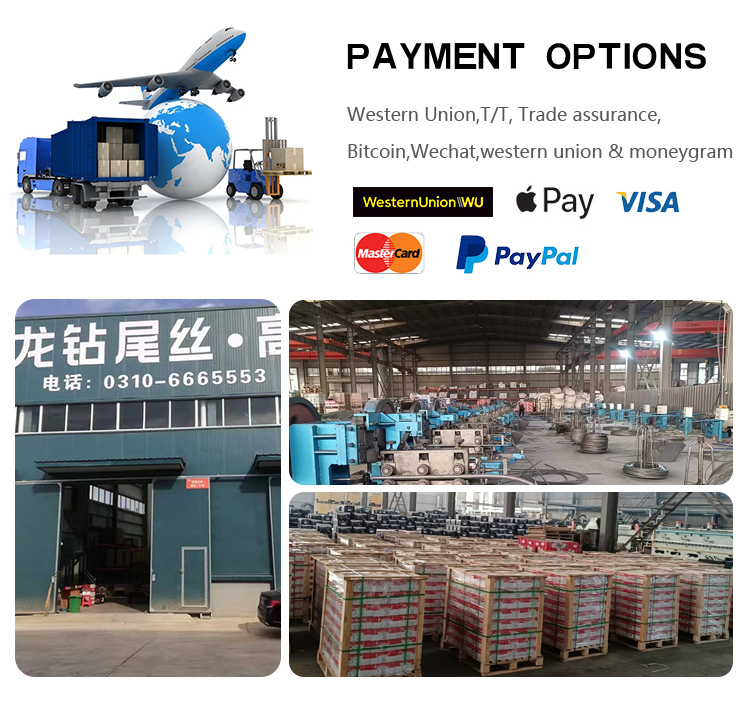

3/16 lock washer factories

5. Finishing The final stage involves surface treatments, such as galvanization or coating, to prevent corrosion. A protective finish enhances the washer’s longevity, especially in harsh environments.

Quality Control

Quality control is of utmost importance in the production of lock washers. Factories implement rigorous testing procedures to ensure each washer meets industry standards such as ASTM (American Society for Testing and Materials) specifications. Testing typically includes

- Dimensional Inspections Ensuring that each washer accurately measures 3/16 inch. - Tensile Strength Testing Assessing the ability of the washer to withstand applied loads without failure. - Corrosion Resistance Testing Evaluating the effectiveness of surface treatments against various corrosive elements.

These quality measures ensure that the end product is reliable and safe for use in critical applications.

Global Significance

The demand for 3/16 inch lock washers is not limited to any single industry or region. Their application spans across automotive manufacturing, aerospace engineering, construction, and electrical equipment. As industries continue to expand globally, the need for high-quality fasteners, including lock washers, grows exponentially.

Countries like China and the United States are home to numerous lock washer factories, producing vast quantities to cater to both domestic and international markets. The competitive landscape encourages constant innovation, with manufacturers striving to improve designs, materials, and production techniques.

Conclusion

The role of 3/16 inch lock washer factories is indispensable in today’s manufacturing ecosystem. These factories not only produce essential components that uphold the integrity of various structures and machines but also contribute to the economic growth and development of industries worldwide. As technology advances and industries evolve, the importance of reliable fastening solutions will only continue to grow, solidifying the lock washer's place in the manufacturing hall of fame.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024