stainless steel flat washer dimensions manufacturer

Understanding Stainless Steel Flat Washer Dimensions and Their Importance

Stainless steel flat washers are essential components in various industrial and construction applications. They serve multiple purposes, including load distribution, prevention of surface damage, and reducing friction between surfaces. Understanding the dimensions of these washers is crucial for ensuring they fit seamlessly into your projects and provide the required support.

What are Flat Washers? Flat washers are thin, flat discs with a hole in the center, designed to be placed under a nut or bolt. When a fastener is tightened, the washer spreads the load over a larger area, which helps prevent damage to the material beneath. Made from stainless steel, these washers are resistant to rust and corrosion, making them suitable for both indoor and outdoor applications.

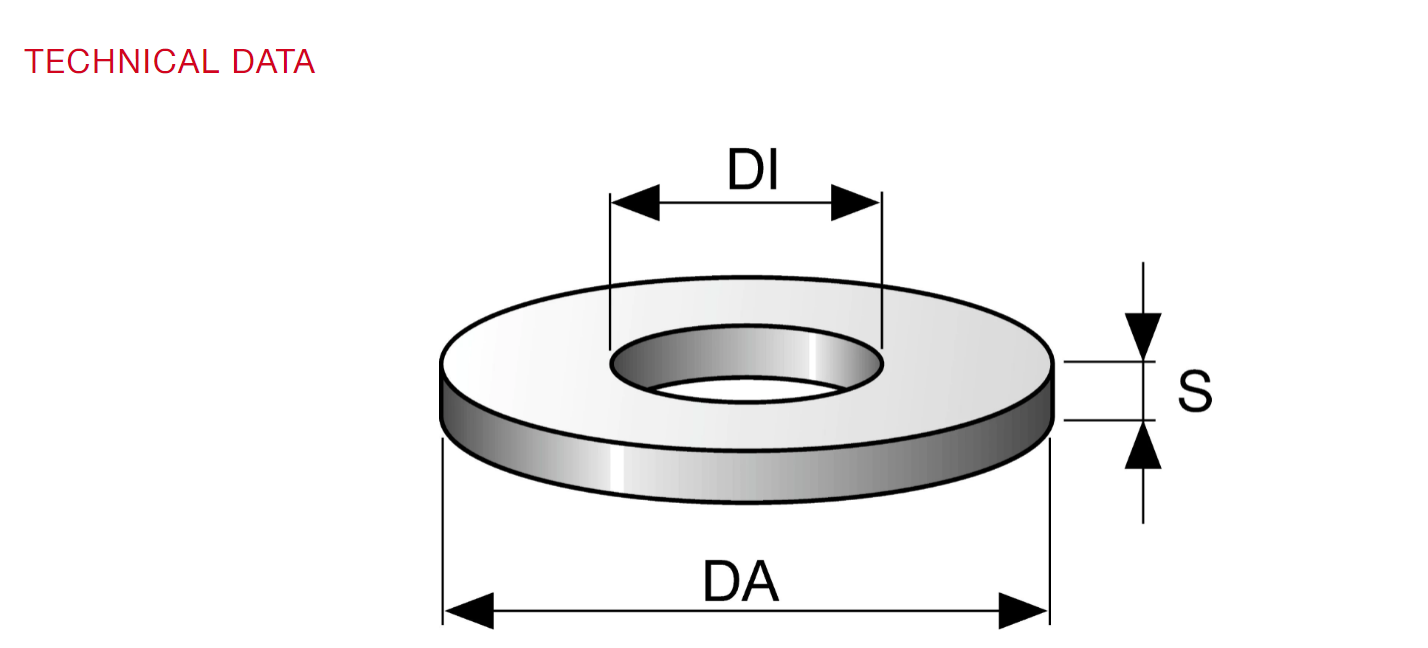

Dimensions that Matter The key dimensions of stainless steel flat washers include their inner diameter, outer diameter, and thickness. These measurements are critical for compatibility with bolts and nuts.

1. Inner Diameter (ID) This is the hole size in the center of the washer. It must match the diameter of the bolt or screw passing through it. Common sizes for inner diameters range from a few millimeters to several centimeters, depending on the application.

stainless steel flat washer dimensions manufacturer

2. Outer Diameter (OD) This dimension is important for the washer’s ability to distribute load. A larger outer diameter generally offers better load distribution, which is particularly vital in applications where pressure and stress are high.

3. Thickness The thickness of the washer affects its strength and load-bearing capacity. Thicker washers can handle greater loads and are less likely to deform under pressure, making them ideal for heavy-duty applications.

Standard Sizes and Variants There are standard sizes for stainless steel flat washers as defined by various engineering standards like ASTM, ANSI, and ISO. The construction and automotive industries often use these standards to ensure parts are interchangeable. Additionally, there are various types of stainless steels, such as 304 and 316, which offer different levels of corrosion resistance. While 304 stainless steel is sufficient for most applications, 316 is preferred in more corrosive environments, such as marine applications.

Choosing the Right Washer Selecting the appropriate stainless steel flat washer involves considering several factors, such as the environment, the types of materials being fastened, and the specific load requirements. Choosing washers that meet or exceed the necessary specifications is crucial for ensuring the durability and longevity of the assembly.

Conclusion In summary, stainless steel flat washers play a crucial role in achieving secure and reliable connections in many applications. By paying close attention to their dimensions—inner diameter, outer diameter, and thickness—manufacturers and builders can ensure that they are using the right components for their projects. As always, when working with materials in demanding environments, opting for high-quality stainless steel washers will yield the best results and enhance the overall integrity of the assembly.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024