Guide to ODM Self Tapping Screw Hole Sizes and Specifications

Understanding ODM Self-Tapping Screw Hole Size Chart

In the world of construction, manufacturing, and DIY projects, the significance of details cannot be overstated. One area where precision is critical is in fastening components together, specifically through the use of self-tapping screws. To ensure optimal fastening, it's essential to understand the appropriate hole sizes for these screws. This is where the ODM self-tapping screw hole size chart comes into play.

What Are Self-Tapping Screws?

Self-tapping screws are specialized fasteners designed to cut their own holes as they are driven into materials. This eliminates the need for pre-drilled holes in many applications, making the assembly process quicker and more efficient. These screws have a sharp tip and unique thread designs that allow them to tap into various materials, including metal, wood, and plastic. While this versatility is a significant advantage, using the correct hole size is crucial to achieve maximum holding power and prevent damage.

The ODM Self-Tapping Screw Hole Size Chart

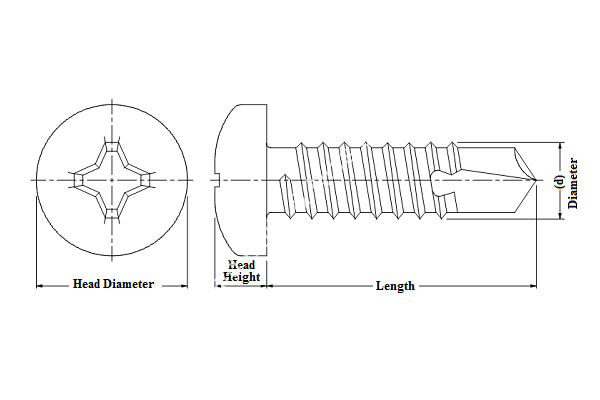

The ODM self-tapping screw hole size chart provides a quick reference for determining the optimal drill bit size for pre-drilling holes that match the specifications of specific self-tapping screws. The chart typically includes

1. Screw Diameter The size of the screw, which is critical because it determines the appropriate hole diameter. 2. Hole Diameter The recommended diameter for pre-drilling, which is slightly smaller than the screw diameter to ensure a tight fit. 3. Material Type Different materials may require different hole sizes due to variances in density and compressibility. 4. Thread Type Self-tapping screws can have various thread configurations, impacting the size of the hole required.

Using the chart correctly prevents issues like stripping the screw hole, damaging the material, and compromising the overall integrity of the fastening

.odm self tapping screw hole size chart

Important Considerations When Using the Chart

1. Material Composition Different materials react uniquely to self-tapping screws. For instance, if you are working with softwood, a smaller hole diameter may be acceptable. Conversely, harder materials like metals may necessitate a larger hole for the screw to tap effectively. 2. Screw Type The various types of self-tapping screws available, such as sheet metal screws, wood screws, and plastic screws, each have specific requirements that must be considered. Always refer to the chart to match the screw type to the appropriate hole size.

3. Environmental Factors Consider the environment in which the screws will be used. For outdoor applications or in high-stress environments, using a screw with a more robust thread design may require adjusting the hole size accordingly.

Applications of Self-Tapping Screws

Self-tapping screws are widely used in multiple applications, including

- Construction Fastening wooden frames, roofing materials, and drywall. - Automotive Assembling metal components and fixtures. - Electronics Securing circuit boards and enclosures where precision is paramount. Their ability to eliminate the need for pre-drilled holes streamlines the assembly process, saving time and labor costs.

Conclusion

Understanding the ODM self-tapping screw hole size chart is essential for anyone involved in fastening applications, whether in construction, manufacturing, or maintenance. Choosing the correct hole size not only enhances the performance of the screws but also ensures the longevity and safety of the assembled structures. When in doubt, always refer to the chart and consider the specific requirements of the materials and screws you are using. With the right knowledge and tools, achieving durable and reliable fastenings becomes a straightforward task.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024