Feb . 11, 2025 12:38

Back to list

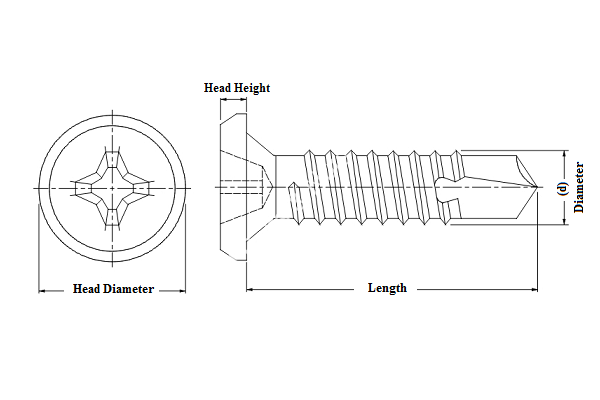

metric self tapping screw size chart

Navigating the intricate world of metric self-tapping screw sizes involves much more than just selecting a screw off the shelf. It requires an understanding of the complexities associated with different dimensions, applications, and the profound impact these might have on the success of your project. A comprehensive metric self-tapping screw size chart serves as an indispensable tool for professionals and DIY enthusiasts alike. This guide aims to provide authoritative insights and expertise to empower users to make well-informed choices when it comes to selecting the right screw for their needs.

The material from which the screw is crafted is equally significant. Common options include stainless steel, carbon steel, and various alloys, each offering distinct advantages and trade-offs. Stainless steel is prized for its resistance to corrosion, making it ideal for outdoor or marine applications. Carbon steel, typically less expensive, provides robust mechanical strength, suitable for medium to heavy-duty applications. Meanwhile, alloyed screws often provide a balanced approach, combining the strengths of multiple metals to meet specific environmental or mechanical challenges. Expert-level insight also underscores the importance of considering the screw's head design. Self-tapping screws are available with diverse head types, each designed for specific applications. For instance, a pan head offers a larger surface area for increased holding power, while a countersunk head lays flush with the material's surface, providing an aesthetic finish alongside its practical sealing capability. Reliability and trustworthiness in screw performance are validated through standards and certifications from recognized bodies like the International Organization for Standardization (ISO) and the Deutsches Institut für Normung (DIN). These standards ensure consistency and quality, reassuring professionals that the screws will perform as expected under specified conditions. Finally, real-world experience highlights the importance of pairing the appropriate screwdriver or bit size with your chosen screw to prevent cam-out, where the screw head is damaged due to a mismatch. This damage is not only frustrating but can also undermine the screw's functionality. To conclude, effectively utilizing a metric self-tapping screw size chart demands a synthesis of knowledge about the screw's dimensions, material compatibility, and application-specific requirements. By considering these factors, professionals can enhance their projects' structural integrity and longevity, establishing a foundation of trust and expertise in their craft.

The material from which the screw is crafted is equally significant. Common options include stainless steel, carbon steel, and various alloys, each offering distinct advantages and trade-offs. Stainless steel is prized for its resistance to corrosion, making it ideal for outdoor or marine applications. Carbon steel, typically less expensive, provides robust mechanical strength, suitable for medium to heavy-duty applications. Meanwhile, alloyed screws often provide a balanced approach, combining the strengths of multiple metals to meet specific environmental or mechanical challenges. Expert-level insight also underscores the importance of considering the screw's head design. Self-tapping screws are available with diverse head types, each designed for specific applications. For instance, a pan head offers a larger surface area for increased holding power, while a countersunk head lays flush with the material's surface, providing an aesthetic finish alongside its practical sealing capability. Reliability and trustworthiness in screw performance are validated through standards and certifications from recognized bodies like the International Organization for Standardization (ISO) and the Deutsches Institut für Normung (DIN). These standards ensure consistency and quality, reassuring professionals that the screws will perform as expected under specified conditions. Finally, real-world experience highlights the importance of pairing the appropriate screwdriver or bit size with your chosen screw to prevent cam-out, where the screw head is damaged due to a mismatch. This damage is not only frustrating but can also undermine the screw's functionality. To conclude, effectively utilizing a metric self-tapping screw size chart demands a synthesis of knowledge about the screw's dimensions, material compatibility, and application-specific requirements. By considering these factors, professionals can enhance their projects' structural integrity and longevity, establishing a foundation of trust and expertise in their craft.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News