Exporter of Lock Washers Prior to Flat Washers

The Importance of Lock Washers Before Flat Washers in Fastening Systems

In the world of fastening technology, the choice of washers plays a critical role in ensuring the integrity and reliability of assembled components. Among various types of washers, lock washers and flat washers serve distinct but complementary purposes in mechanical assemblies. Understanding when and why to use lock washers before flat washers can significantly enhance the performance of a bolted joint.

What are Lock Washers?

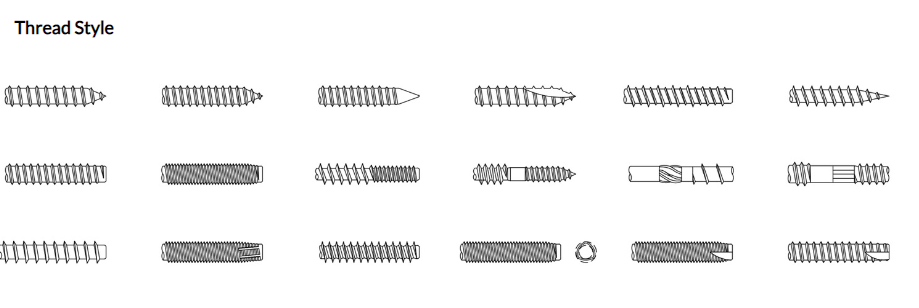

Lock washers are specially designed to prevent loosening of nuts and bolts due to vibration or torque. These washers are characterized by their curved or split shapes which create inherent friction when compressed. Numerous varieties of lock washers, such as split, toothed, and wave washers, offer unique benefits depending on the application. When properly used, lock washers maintain tension in the joint by preventing movement, effectively enhancing the overall stability of the assembly.

What are Flat Washers?

Flat washers are simple, circular discs made from various materials including metal, plastic, and rubber. Their primary function is to distribute the load of a threaded fastener evenly over the component surface, thereby preventing damage or deformation. Flat washers also serve as spacers, isolators, and seals, and are often used in conjunction with lock washers to create a more secure fastening solution.

The Role of Lock Washers Before Flat Washers

Using lock washers before flat washers can be particularly advantageous in numerous settings. First and foremost, the primary function of a lock washer is to provide locking capabilities. This proactive approach tackles the problem of spontaneous loosening in dynamic environments where components are subjected to vibrations or frequent motion.

When a lock washer is placed directly under the nut (or bolt head), it engages with the surface material and exerts additional tension that helps secure the fastener in place. The flat washer, positioned underneath the lock washer in this assembly, further assists in maintaining this tension by distributing the compressive force across a larger area. This layered strategy minimizes the risk of damaging the underlying component while maximizing the effectiveness of the lock washer.

lock washer before flat washer exporter

Advantages of This Configuration

1. Enhanced Stability By employing a lock washer first, one establishes a reliable base to hold the bolt securely. The flat washer's role afterward ensures even load distribution, leading to a more stable fastening assembly overall.

2. Minimized Wear and Tear Using these two washers together reduces the wear on the bolt and the surface material. The flat washer absorbs some of the load, helping to prevent galling or deformation of the surfaces connected by the fastening assembly.

3. Increased Longevity This combination allows for an extended lifespan of bolt joints, especially in applications exposed to extreme conditions, as the lock washer's locking action helps maintain tension over time, significantly reducing the risk of joint failure.

4. Flexibility in Design Different combinations of lock washers and flat washers can be employed to meet specific design requirements. This versatility allows engineers to develop custom fastening solutions tailored for unique operational environments.

Considerations for Use

While the combination of lock washers and flat washers can bring numerous benefits, it is essential to consider the specific application's needs before implementation. Factors such as load type, environmental conditions, and material properties should be taken into account. Moreover, it is crucial to ensure that both washers fit appropriately to the size and specifications of the fasteners being used to maximize their effectiveness.

Conclusion

Incorporating lock washers before flat washers in fastening systems is a practical strategy to enhance the performance and durability of mechanical assemblies. As industry technology advances, understanding these fundamental components will remain vital for engineers, designers, and manufacturers alike. By adopting this approach, they can ensure that the fastening solutions they implement are resilient, reliable, and capable of withstanding the rigors of modern engineering challenges. Whether in automotive, aerospace, construction, or any other industry, the significance of this combination cannot be overlooked, ultimately contributing to safer and more efficient mechanical systems.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024