ফেব্রু. . 18, 2025 07:23

Back to list

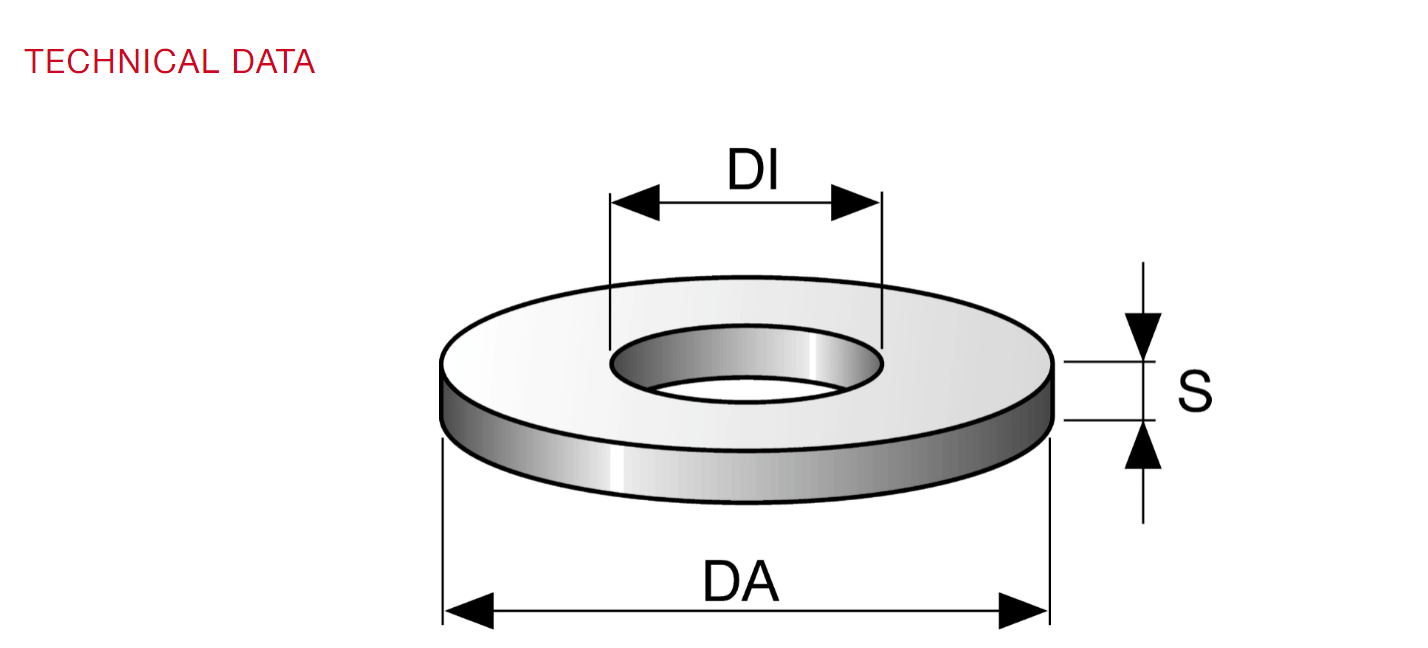

din125 plain washer flat washer

Choosing the right order to assemble washers is crucial in many industries that depend on secure and stable mechanical connections. Since washers come in different types, each serving a specific purpose, sequencing them correctly can significantly affect both the immediate performance and long-term durability of a joint. Two common types that often appear together in assemblies are spring washers and flat washers. Understanding the strategic placement of a spring washer before a flat washer could make a profound difference in various applications.

Springs washers excel in scenarios that demand not only vibration resistance but also temperature fluctuation accommodation. They maintain consistent tension, thus keeping the assembly rigid even when materials expand and contract with temperature changes—a facet crucial in environments exposed to cyclical thermal variations. A common concern in the mechanical assembly world is the potential for damaging the washer-made contact surfaces. By utilizing a flat washer in direct contact with the surface, any rotational forces from tightening the fastener are spread across the surface rather than concentrated in one spot. This effect reduces the likelihood of gouging or distortion, particularly in assemblies that may require periodic disassembly and reassembly for maintenance or inspection. The perceived downside of introducing two washers into one joint may be the slightly increased material cost and additional steps in the assembly process. However, the benefits of enhanced performance integrity, comprehensive load distribution, and resilient vibration dampening far outweigh these concerns in critical applications. In designing reliable mechanical joints, expertise in the correct washer sequence is pivotal. Engineers and technicians knowledgeable about washer roles and practical applications contribute significantly to ensuring joint longevity and operational safety. The use of a spring washer before a flat washer exemplifies efficiency in mechanical design, assuring trust through enhanced durability and reliability. As industries continue to seek out optimizations in performance and cost, such nuanced understandings remain invaluable assets in delivering products that stand up to the rigors of modern use.

Springs washers excel in scenarios that demand not only vibration resistance but also temperature fluctuation accommodation. They maintain consistent tension, thus keeping the assembly rigid even when materials expand and contract with temperature changes—a facet crucial in environments exposed to cyclical thermal variations. A common concern in the mechanical assembly world is the potential for damaging the washer-made contact surfaces. By utilizing a flat washer in direct contact with the surface, any rotational forces from tightening the fastener are spread across the surface rather than concentrated in one spot. This effect reduces the likelihood of gouging or distortion, particularly in assemblies that may require periodic disassembly and reassembly for maintenance or inspection. The perceived downside of introducing two washers into one joint may be the slightly increased material cost and additional steps in the assembly process. However, the benefits of enhanced performance integrity, comprehensive load distribution, and resilient vibration dampening far outweigh these concerns in critical applications. In designing reliable mechanical joints, expertise in the correct washer sequence is pivotal. Engineers and technicians knowledgeable about washer roles and practical applications contribute significantly to ensuring joint longevity and operational safety. The use of a spring washer before a flat washer exemplifies efficiency in mechanical design, assuring trust through enhanced durability and reliability. As industries continue to seek out optimizations in performance and cost, such nuanced understandings remain invaluable assets in delivering products that stand up to the rigors of modern use.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News