জানু. . 23, 2025 04:12

Back to list

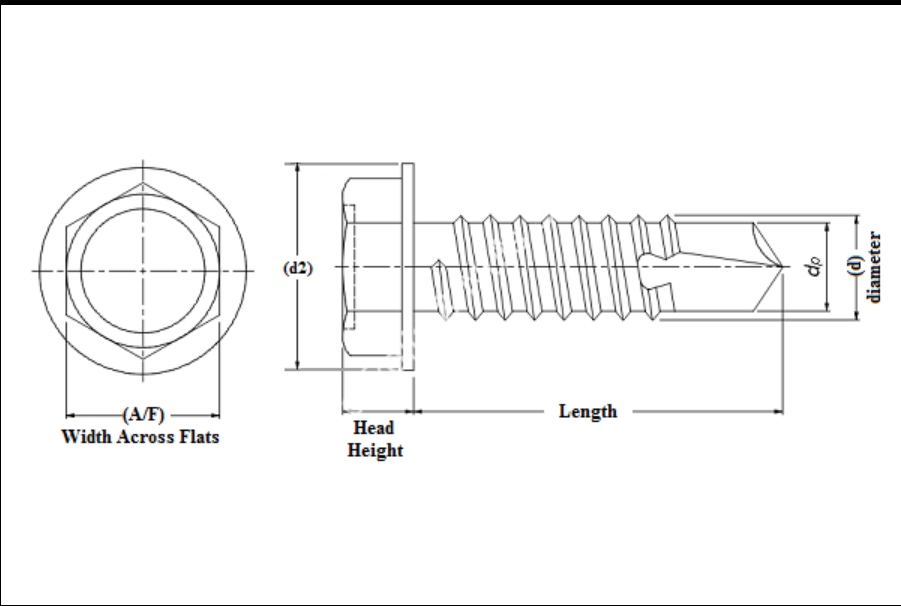

galvanized pan head self tapping screw

Pan head self-tapping screws are an indispensable component in many construction and DIY projects, known for their unique design and versatility. Their distinct pan-shaped head provides a flat bearing surface, making them ideal for fastening materials securely without the risk of over-tightening or material damage. The self-tapping nature of these screws allows them to create their own threads as they are driven into the material, which not only simplifies the assembly process but also ensures a tighter, more durable fit.

Authoritativeness in the use of these screws is demonstrated by adherence to industry standards and best practices. Knowledgeable practitioners will refer to guidelines such as those set by the International Organization for Standardization (ISO) or the American National Standards Institute (ANSI) to ensure the screws meet necessary performance criteria. Such adherence not only guarantees the quality and durability of the project but also enhances the credibility of the work completed. Trustworthiness is further emphasized by acknowledging the feedback from users who have employed these screws in various projects. Testimonials from both consumers and industry professionals highlight the reliability of pan head self-tapping screws in maintaining structural integrity over time. For instance, aerospace engineers often praise their application in aircraft assembly, where even the smallest component must meet rigorous quality standards to ensure passenger safety. In conclusion, pan head self-tapping screws represent a marriage of practical utility and technical precision. Their capacity to adapt to multiple materials without requiring auxiliary processes signifies an evolution in fastening technology that professionals across sectors appreciate. Choosing the right screw for the task involves understanding not only the physical demands of the project but also the nuanced capabilities and limitations of the screw design itself. Through expert selection and application, these screws continue to reinforce their position as a fundamental element in achieving both structurally sound and aesthetically pleasing results.

Authoritativeness in the use of these screws is demonstrated by adherence to industry standards and best practices. Knowledgeable practitioners will refer to guidelines such as those set by the International Organization for Standardization (ISO) or the American National Standards Institute (ANSI) to ensure the screws meet necessary performance criteria. Such adherence not only guarantees the quality and durability of the project but also enhances the credibility of the work completed. Trustworthiness is further emphasized by acknowledging the feedback from users who have employed these screws in various projects. Testimonials from both consumers and industry professionals highlight the reliability of pan head self-tapping screws in maintaining structural integrity over time. For instance, aerospace engineers often praise their application in aircraft assembly, where even the smallest component must meet rigorous quality standards to ensure passenger safety. In conclusion, pan head self-tapping screws represent a marriage of practical utility and technical precision. Their capacity to adapt to multiple materials without requiring auxiliary processes signifies an evolution in fastening technology that professionals across sectors appreciate. Choosing the right screw for the task involves understanding not only the physical demands of the project but also the nuanced capabilities and limitations of the screw design itself. Through expert selection and application, these screws continue to reinforce their position as a fundamental element in achieving both structurally sound and aesthetically pleasing results.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News