Leading Manufacturers of M2 Self Tapping Screws for Various Applications

The Landscape of M2 Self-Tapping Screw Factories An Overview

In today's rapidly evolving manufacturing landscape, the demand for precision and durability in fasteners has given rise to specialized factories producing M2 self-tapping screws. These screws, characterized by their ability to create their own thread as they penetrate materials, are crucial in various applications across industries including electronics, construction, and automotive.

Understanding M2 Self-Tapping Screws

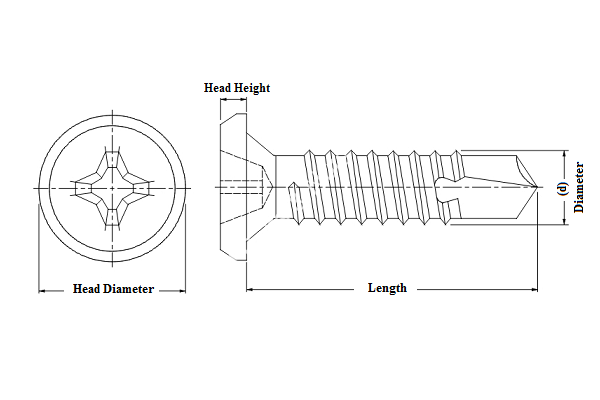

M2 self-tapping screws are a specific category of screws with a nominal diameter of 2 millimeters. They are designed to work with materials that may not always be pre-drilled, allowing for easier and quicker assembly. The innovative design of these screws features sharp threads that enable them to cut through material, forming secure fastening without the need for additional hardware. This is particularly beneficial in applications where space is limited or in environments where pre-drilling isn't feasible.

The Role of Factories in Production

Manufacturing M2 self-tapping screws requires intricate processes that ensure both efficiency and high-quality output. Factories dedicated to the production of these screws must adhere to stringent quality control standards, as even slight deviations can affect performance. High-caliber factories utilize advanced machinery equipped with the latest technology in screw production. Automated processes, such as CNC (Computer Numerical Control) machining, are often employed to achieve precision in the manufacturing process.

The production begins with the selection of appropriate materials, usually carbon steel, stainless steel, or brass, depending on the intended applications of the screws. Heat treatment processes are then applied to enhance the mechanical properties, ensuring that the screws have the strength and longevity needed for their specific applications.

Market Demand and Trends

The market for M2 self-tapping screws has grown in tandem with advancements in technology, particularly in the electronics and automotive sectors, where lightweight and compact designs are crucial. The rapid expansion of these industries, driven by consumer demand for electronics such as smartphones, laptops, and electric vehicles, has increased the necessity for high-quality fasteners like M2 self-tapping screws.

m2 self tapping screw factories

Moreover, sustainability has emerged as a key trend within the manufacturing realm. Factories are increasingly adopting eco-friendly practices, recycling materials, and reducing energy consumption during production. This approach not only benefits the environment but also appeals to consumers who are more conscious about the sustainability of the products they use.

Global Distribution of Manufacturing Facilities

Factories that specialize in M2 self-tapping screws are spread across the globe, with significant concentrations in countries known for their manufacturing prowess, such as China, Germany, and the United States. Each region contributes unique advantages. For example, China is recognized for its cost-effective production, allowing for large-scale manufacturing, while Germany’s factories are noted for their high-quality engineering and innovative designs.

Additionally, advancements in logistics and supply chain management have facilitated the distribution of these screws worldwide, allowing manufacturers to reach international markets more efficiently. This has resulted in increased competitiveness among factories, prompting continuous improvements in production processes and product quality.

Future Outlook

The future of M2 self-tapping screw factories looks promising as industries continue to evolve. With the increasing complexity of products and the need for rapid assembly, the demand for self-tapping solutions will likely grow. Moreover, as more manufacturers recognize the importance of automation and digital technologies, factories will continue to incorporate smart manufacturing practices, further enhancing efficiency and precision.

As environmental awareness rises, factories will also need to adapt to meet sustainability regulations and consumer expectations. This transition not only aids in securing a market position but also contributes positively to the planet.

Conclusion

In conclusion, M2 self-tapping screw factories play a vital role in the global manufacturing landscape. Through advancements in technology, efficient production processes, and an increasing focus on sustainability, these factories are poised to meet the growing demands of various industries. As the market continues to evolve, so too will the capabilities and innovations of M2 self-tapping screw manufacturing, driving the industry forward into a future filled with possibilities.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024