china self tapping screw head size

Understanding China Self-Tapping Screw Head Size

In the world of construction, manufacturing, and DIY projects, self-tapping screws have become essential components that facilitate efficient assembly and secure fastening. Among the various factors deciding the appropriateness of a screw for a specific application is the size and type of the screw head. This article aims to provide insight into the self-tapping screw head size, particularly in the context of products manufactured in China.

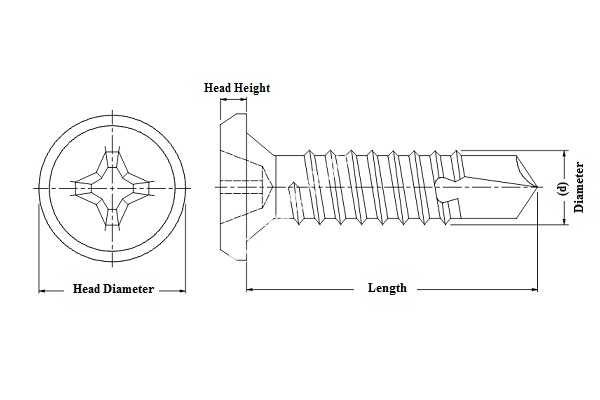

Self-tapping screws are specially designed to tap their own holes while being driven into materials like wood, metal, or plastic. The unique design allows them to create threads in the material, eliminating the need for pre-drilling holes. This feature not only saves time but also enhances the integrity of the connection. However, to fully leverage the benefits of self-tapping screws, one needs to choose the right head size and type.

Understanding China Self-Tapping Screw Head Size

1. Flat Head Screws Flat head screws are designed to sit flush with the material being fastened. This design is particularly useful in applications where a smooth surface is essential, such as automotive or furniture assembly. The screw head’s diameter plays a crucial role in ensuring a secure hold while maintaining a clean finish.

china self tapping screw head size

2. Pan Head Screws These screws have a slightly rounded head that provides a larger bearing surface. They are ideal for applications where a stronger grip is necessary, and they often allow for quicker installation. Choosing the correct pan head size ensures proper torque and reduces the risk of stripping the screw.

3. Hex Head Screws Hex head screws are distinguished by their hexagonal shape, which allows for the application of higher torque using a wrench. This type is widely used in heavy-duty applications such as construction and machinery. When it comes to hex head sizes, one must consider the wrench compatibility to ensure effective fastening without damaging the screw.

4. Truss Head Screws Truss head screws are characterized by their wide, low-profile head that distributes the load over a larger area. This type is particularly beneficial in thin materials where a larger bearing surface can prevent pull-through. Correct selection of truss head size aids in maintaining the integrity of the attachment.

When sourcing self-tapping screws from China, it’s vital to reference precise specifications. Most manufacturers provide detailed product catalogs that outline screw dimensions, including head size, which can help in making informed decisions. Additionally, compliance with international and national standards ensures that the screws meet expected quality and performance criteria.

In conclusion, understanding the head size of self-tapping screws is crucial for selecting the right fastener for your project. The variety of head types available, along with their associated sizes, allows for customization based on the demands of the application. As China continues to be a leading manufacturer of self-tapping screws, ensuring familiarity with their standards and specifications empowers buyers to make informed choices that enhance the efficiency and durability of their projects. Whether you are involved in industrial applications or simple home improvements, the right self-tapping screw can make all the difference.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024