3 8 head self tapping screw manufacturer

Understanding the Importance of 3% 208% Head Self-Tapping Screws

In the realm of fasteners, self-tapping screws have established themselves as crucial components in various industries, ranging from construction to electronics. Among the myriad options available, the 3% 208% head self-tapping screw has garnered significant attention due to its unique design and optimal performance. This article delves into what makes these screws stand out, their applications, and the significance of selecting the right manufacturer.

What are Self-Tapping Screws?

Self-tapping screws are specialized fasteners designed to create their own thread in the material they are driven into. This unique capability eliminates the need for pre-drilled holes, making the assembly process faster and more efficient. The 3% 208% head variant refers to a specific type of head design that offers enhanced gripping power and improved aesthetics. The head's features may include a flat design, making it suitable for flush applications or a rounded shape for a more finished look.

Advantages of 3% 208% Head Self-Tapping Screws

1. Efficient Installation These screws are engineered to penetrate various materials such as metal, wood, and plastic without the necessity of drilling pilot holes. As a result, they ensure a quicker installation process, thereby saving time and labor costs.

2. Strong Grip The 3% 208% head design allows for a superior grip on the material, reducing the likelihood of slippage during installation. This is particularly important in high-stress applications where the integrity of the assembly is paramount.

3 8 head self tapping screw manufacturer

3. Versatility These screws can be used in a wide range of applications, including furniture assembly, metal fabrication, and automotive manufacturing. Their adaptability makes them a go-to choice for manufacturers and builders alike.

4. Cost-Effectiveness By combining the drilling and fastening processes, self-tapping screws, particularly the 3% 208% head type, can lower overall production costs. Fewer tools and reduced labor translate to savings without compromising quality.

The Choice of Manufacturer

Selecting the right manufacturer for self-tapping screws is critical to ensure reliability and performance. A reputable manufacturer will implement stringent quality control measures and use high-grade materials to produce their fasteners. This commitment to quality translates to screws that can withstand varying environmental conditions, resist corrosion, and maintain structural integrity.

When searching for a manufacturer, it is essential to consider their experience in the industry, customer reviews, and capacity to customize products according to specific needs. A good manufacturer will also provide technical support and timely delivery, further contributing to a successful project execution.

Conclusion

The 3% 208% head self-tapping screw represents a blend of efficiency, strength, and design versatility. Understanding their advantages and selecting a reliable manufacturer can lead to improved productivity and quality in a wide array of applications. As industries continue to evolve, these screws will undoubtedly remain a vital component in modern assembly processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

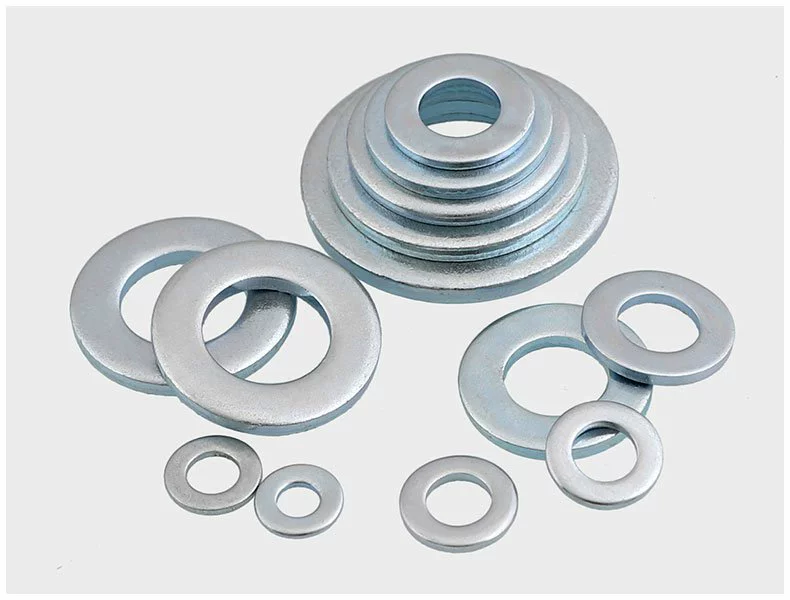

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024