студ . 20, 2025 07:14

Back to list

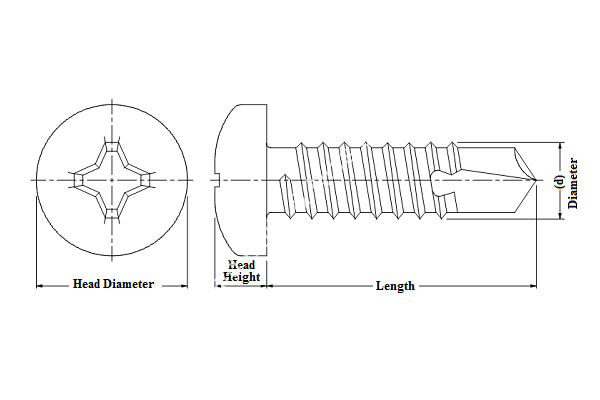

self tapping screw sizes chart

Self-tapping screws are pivotal in both DIY and professional construction projects. Selecting the right size is crucial for ensuring the durability and strength of your assembly, as well as for maintaining the integrity of the materials involved. Understanding the nuances among different self-tapping screw sizes is essential for anyone aiming to perform high-quality workmanship.

However, experiencing the process of matching screw size with application comes from hands-on practice. Having worked on numerous projects, professionals quickly learn the importance of trial and error. Starting with a general size chart, one can make adjustments based on material behavior, application specifics, and environmental conditions. For instance, when working with softer woods, selecting a larger coarse-thread screw can counteract the reduced holding power of the material. Conversely, for dense metals, one might opt for a smaller, fine-thread screw to ensure precision and reduce the likelihood of damaging the surface. Professional expertise also involves understanding that self-tapping screws differ from self-drilling screws. The latter goes a step further by featuring a drill point, allowing them to carve their insertion path into harder materials without pre-drilling. Recognizing this distinction aids in choosing the right tool for the job and ensuring efficiency. In terms of building trust and demonstrating authority, it's crucial to reflect on past projects. Sharing insights from diverse experiences, such as construction of outdoor structures or metal framing, lends credibility. Discussing challenges faced and how selecting the correct screw sizes helped overcome these obstacles adds depth to any conversation about these essential fasteners. Furthermore, consistently updating your knowledge based on industry standards, new technologies, and emerging trends strengthens one’s expertise. As materials evolve, so do fastener technologies. Staying informed about new coatings, designs, and materials for self-tapping screws helps in making informed decisions that enhance structural integrity. In summary, selecting the right self-tapping screw size requires a blend of theoretical knowledge and practical experience. Considering factors such as diameter, thread type, and material compatibility are requisite for optimum results. By continuing to engage with new challenges and sharing insights, knowledge about self-tapping screws' sizes and applications becomes not only comprehensive but also authoritative. This ensures projects not only meet but exceed expected standards of safety and durability.

However, experiencing the process of matching screw size with application comes from hands-on practice. Having worked on numerous projects, professionals quickly learn the importance of trial and error. Starting with a general size chart, one can make adjustments based on material behavior, application specifics, and environmental conditions. For instance, when working with softer woods, selecting a larger coarse-thread screw can counteract the reduced holding power of the material. Conversely, for dense metals, one might opt for a smaller, fine-thread screw to ensure precision and reduce the likelihood of damaging the surface. Professional expertise also involves understanding that self-tapping screws differ from self-drilling screws. The latter goes a step further by featuring a drill point, allowing them to carve their insertion path into harder materials without pre-drilling. Recognizing this distinction aids in choosing the right tool for the job and ensuring efficiency. In terms of building trust and demonstrating authority, it's crucial to reflect on past projects. Sharing insights from diverse experiences, such as construction of outdoor structures or metal framing, lends credibility. Discussing challenges faced and how selecting the correct screw sizes helped overcome these obstacles adds depth to any conversation about these essential fasteners. Furthermore, consistently updating your knowledge based on industry standards, new technologies, and emerging trends strengthens one’s expertise. As materials evolve, so do fastener technologies. Staying informed about new coatings, designs, and materials for self-tapping screws helps in making informed decisions that enhance structural integrity. In summary, selecting the right self-tapping screw size requires a blend of theoretical knowledge and practical experience. Considering factors such as diameter, thread type, and material compatibility are requisite for optimum results. By continuing to engage with new challenges and sharing insights, knowledge about self-tapping screws' sizes and applications becomes not only comprehensive but also authoritative. This ensures projects not only meet but exceed expected standards of safety and durability.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News