Drywall Screw Spacing Guidelines for Optimal Installation and Support

When it comes to drywall installation, understanding the correct screw spacing is crucial for achieving a sturdy and professional finish. The OEM drywall screw spacing chart serves as a vital reference for contractors and DIY enthusiasts alike, ensuring that drywall sheets are properly secured to the underlying structure.

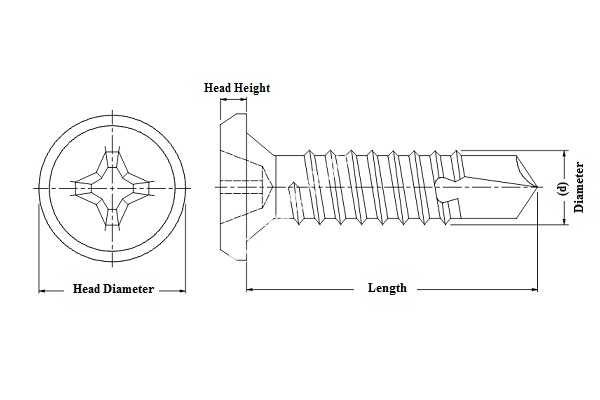

Typically, drywall is attached to wooden or metal studs using drywall screws, which are specifically designed to penetrate the material without causing splitting

. The spacing of these screws depends on several factors, including the type of drywall being used and the configuration of the wall structure.For standard 1/2-inch drywall, which is commonly used in residential applications, the general rule of thumb is to place screws every 16 inches on center along the edges of the drywall and every 24 inches on center in the field. This spacing helps to distribute the load evenly and provides adequate support to prevent sagging over time. When working with thicker drywall, such as 5/8-inch, it is recommended to maintain the same spacing for edge screws while potentially increasing the field screw spacing. This adjustment is particularly important in applications requiring additional fire resistance or soundproofing, such as in media rooms or shared walls in apartment buildings.

In addition to horizontal spacing, vertical spacing is equally important. For ceilings or overhead installations, screws should be placed at 12 inches on center to accommodate the additional weight and gravity. Given that ceiling installations have less structural support compared to walls, this tighter screw spacing minimizes the risk of sagging and ensures a solid installation.

oem drywall screw spacing chart

Moreover, attention should be paid to the type of material the screws will be driven into. For instance, if you are fastening drywall to metal studs, it's recommended to use screws designed specifically for that purpose. Metal studs require self-tapping screws to ensure that the joint is secure, while standard screws are adequate for wood framing.

The OEM drywall screw spacing chart also takes into account other factors, such as type of finish desired. For a level 5 finish, which requires a smooth wall surface ideal for high-gloss paint and textures, screws should be spaced more closely, often at 12 inches apart. This dense spacing provides a stronger base for finishing and minimizes the chances of detecting fasteners through the surface.

Ultimately, consistently following the OEM drywall screw spacing chart will lead to an improved and durable drywall installation. It is essential to be knowledgeable about the appropriate techniques and standards, as they not only affect the aesthetics of the finished wall but also its overall integrity and performance over time. Whether you're a seasoned contractor or a first-time DIYer, adhering to these spacing guidelines will ensure your project stands the test of time.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024