Self-Drilling ODM Screws for Efficient and Reliable Construction Applications

Understanding ODM Screw Self-Drilling Technology

In modern construction and manufacturing, the need for efficient fastening methods is paramount. Among the various fastening technologies available, ODM screw self-drilling screws have emerged as a vital tool for builders, engineers, and DIY enthusiasts alike. These screws are specifically designed to provide a reliable and fast solution for joining materials without the necessity of pre-drilling, streamlining the construction process and ensuring optimal performance. This article delves into the characteristics, applications, and benefits of ODM screw self-drilling technology.

What is an ODM Screw Self-Drilling Screw?

ODM (Original Design Manufacturer) screw self-drilling screws are specially designed fasteners characterized by their unique tip design that allows them to drill their own hole as they are installed. Unlike traditional screws, which require a pre-drilled hole for insertion, self-drilling screws feature a sharp point that can pierce through various materials, including metal, wood, and plastic, making them highly versatile.

The design typically includes a drill bit tip, which enables the screw to penetrate the material efficiently. This feature not only enhances the speed of installation but also reduces the risk of material damage, as there is no need for an additional drilling operation.

Key Features of ODM Screw Self-Drilling Screws

1. Material Options ODM screws are available in a variety of materials, including stainless steel, carbon steel, and various coatings to enhance corrosion resistance. This versatility allows them to be used in different environments, from outdoor structural applications to indoor fixtures.

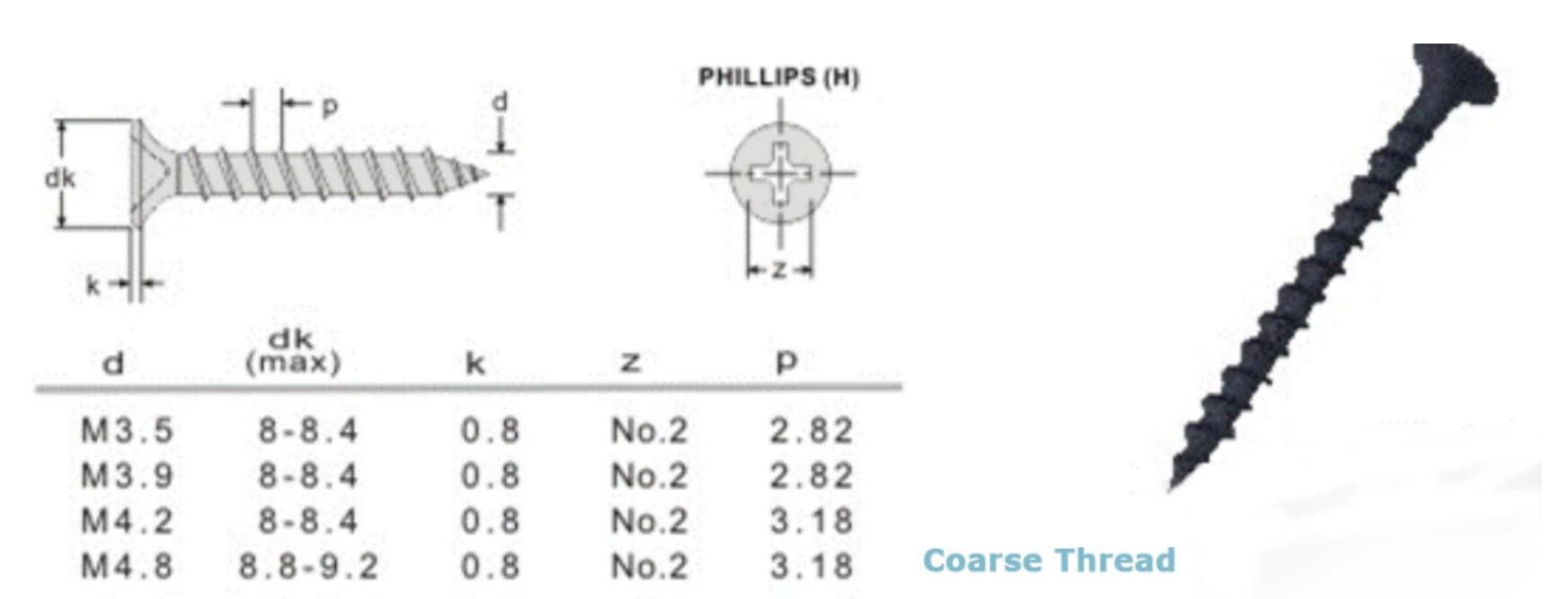

2. Variety of Heads and Threads Self-drilling screws come in multiple head types (such as pan head, flat head, or hex head) and thread designs (fine or coarse). This diversity ensures that there is an ODM screw suitable for any application, whether it’s securing metal sheets or fastening wood materials.

3. Ease of Use The self-drilling nature of these screws eliminates the need for separate drilling tools or additional steps, which greatly speeds up the installation process. This ease of use is particularly beneficial in large-scale construction projects where time efficiency is crucial.

4. Strong Holding Power The thread design and drilling capability provide excellent hold and stability in the materials being joined. This feature makes self-drilling screws suitable for structural components where strength is necessary.

Applications of ODM Screw Self-Drilling Technology

Self-drilling screws are widely used in various applications across different industries. Some common applications include

odm screw self drilling

- Metal Fabrication Self-drilling screws are extensively used in the metalworking industry for joining metal sheets, roofing, and cladding. Their ability to penetrate metal without pre-drilling saves time and enhances overall efficiency.

- Woodworking In woodworking, ODM screws can fasten wooden beams, furniture, and fixtures effectively. Their sharp tips allow for clean entry into wood, preventing splitting and misalignment.

- Construction In general construction, self-drilling screws are used for assembling frameworks, installing drywall, and securing insulation materials. Their adaptability makes them suitable for both residential and commercial projects.

- Automotive and Machinery These screws are also employed in the automotive sector, where they are used in assembling various vehicle components, owing to their reliability and strength

.Benefits of Using ODM Screw Self-Drilling Technology

1. Time-Saving The reduction of the drilling process significantly speeds up installation times, allowing for quicker project completion and reduced labor costs.

2. Versatility With the ability to work on multiple materials, ODM screws eliminate the need for specialized fasteners for different applications.

3. Cost-Effective The durability and efficiency of these screws can lead to overall cost savings in both materials and labor.

4. Enhanced Performance The design of these screws ensures a strong and stable connection between materials, minimizing the chances of failure over time.

Conclusion

ODM screw self-drilling technology stands out as an essential advancement in fastening solutions, offering efficiency and versatility across various industries. Their unique design facilitates faster installation without sacrificing strength, making them a preferred choice for modern construction projects. As the industry continues to evolve, the adoption of innovative fastening techniques like self-drilling screws will likely play a critical role in enhancing productivity and performance in construction and manufacturing.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024