Mar . 05, 2025 07:11

Back to list

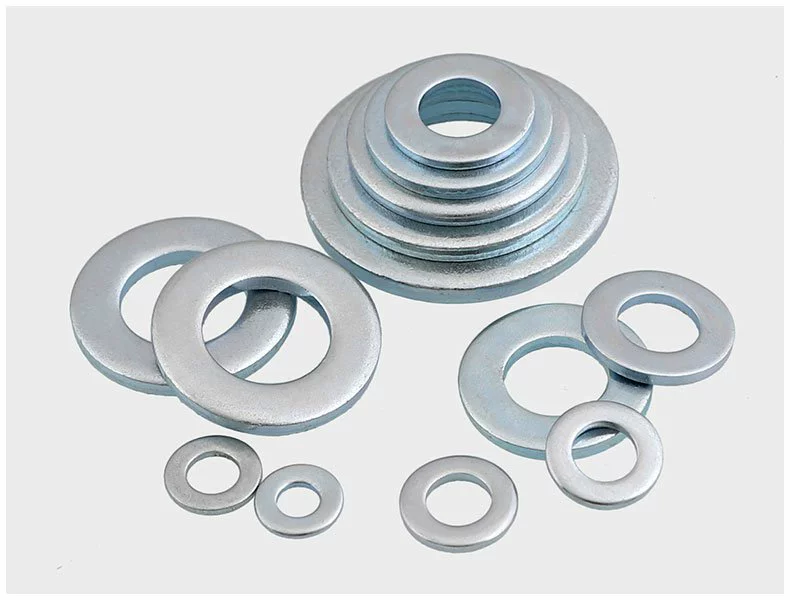

DIN125 Flat Washer ,ZP , YZP, BLACK , PLAIN

Choosing the right washer for bolted connections can significantly impact assembly reliability and longevity. Among the various types of washers, Nord-Lock washers and spring washers stand out due to their unique designs and functionalities. This guide delves into the specifics of these two options, providing insights into their applications, strengths, and limitations, to help users make informed decisions.

Authoritativeness Despite their widespread use, spring washers have garnered mixed reviews over the years due to limitations under extreme vibrations or continuous load cycles. While industrial standards such as DIN (Deutsches Institut für Normung) incorporate spring washers into their specifications, the evolving requirements of modern machinery increasingly demand more sophisticated solutions like the Nord-Lock washer. Trustworthiness For low-vibration applications, users find spring washers sufficient and economical. Nevertheless, for scenarios requiring frequent tightening, there have been reported cases of reduced reliability, leading to a search for more robust alternatives. Comparative Analysis A side-by-side analysis of the Nord-Lock washer and the spring washer reveals a clear differentiation in capability and application 1. Vibration Resistance Nord-Lock washers excel in conditions of high vibration, ensuring bolt security through pre-tensioned joints. Spring washers, although effective for standard applications, may require frequent re-tightening when subjected to dynamic stresses. 2. Material and Durability Nord-Lock washers are manufactured using high-grade materials that withstand corrosion and fatigue, ensuring long-term performance. Spring washers, particularly when made from non-stainless materials, may corrode over time, affecting functionality. 3. Installation and Maintenance Both washers are relatively easy to install, yet Nord-Lock’s edge lies in reduced need for maintenance. Industrial feedback highlights the time savings and reduction in labor costs through using Nord-Lock systems in contrast to the traditional spring washer. Conclusion When determining the appropriate washer solution for your bolting requirements, consider the operational environment and mechanical stresses involved. Nord-Lock washers offer unparalleled vibration resistance and clamp security, making them ideal for high-stakes applications subjected to dynamic forces. Meanwhile, spring washers remain a viable option for less demanding conditions. Ultimately, either option should be aligned with engineering assessments and usage requirements to ensure optimal performance and safety.

Authoritativeness Despite their widespread use, spring washers have garnered mixed reviews over the years due to limitations under extreme vibrations or continuous load cycles. While industrial standards such as DIN (Deutsches Institut für Normung) incorporate spring washers into their specifications, the evolving requirements of modern machinery increasingly demand more sophisticated solutions like the Nord-Lock washer. Trustworthiness For low-vibration applications, users find spring washers sufficient and economical. Nevertheless, for scenarios requiring frequent tightening, there have been reported cases of reduced reliability, leading to a search for more robust alternatives. Comparative Analysis A side-by-side analysis of the Nord-Lock washer and the spring washer reveals a clear differentiation in capability and application 1. Vibration Resistance Nord-Lock washers excel in conditions of high vibration, ensuring bolt security through pre-tensioned joints. Spring washers, although effective for standard applications, may require frequent re-tightening when subjected to dynamic stresses. 2. Material and Durability Nord-Lock washers are manufactured using high-grade materials that withstand corrosion and fatigue, ensuring long-term performance. Spring washers, particularly when made from non-stainless materials, may corrode over time, affecting functionality. 3. Installation and Maintenance Both washers are relatively easy to install, yet Nord-Lock’s edge lies in reduced need for maintenance. Industrial feedback highlights the time savings and reduction in labor costs through using Nord-Lock systems in contrast to the traditional spring washer. Conclusion When determining the appropriate washer solution for your bolting requirements, consider the operational environment and mechanical stresses involved. Nord-Lock washers offer unparalleled vibration resistance and clamp security, making them ideal for high-stakes applications subjected to dynamic forces. Meanwhile, spring washers remain a viable option for less demanding conditions. Ultimately, either option should be aligned with engineering assessments and usage requirements to ensure optimal performance and safety.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News