лют . 11, 2025 17:41

Back to list

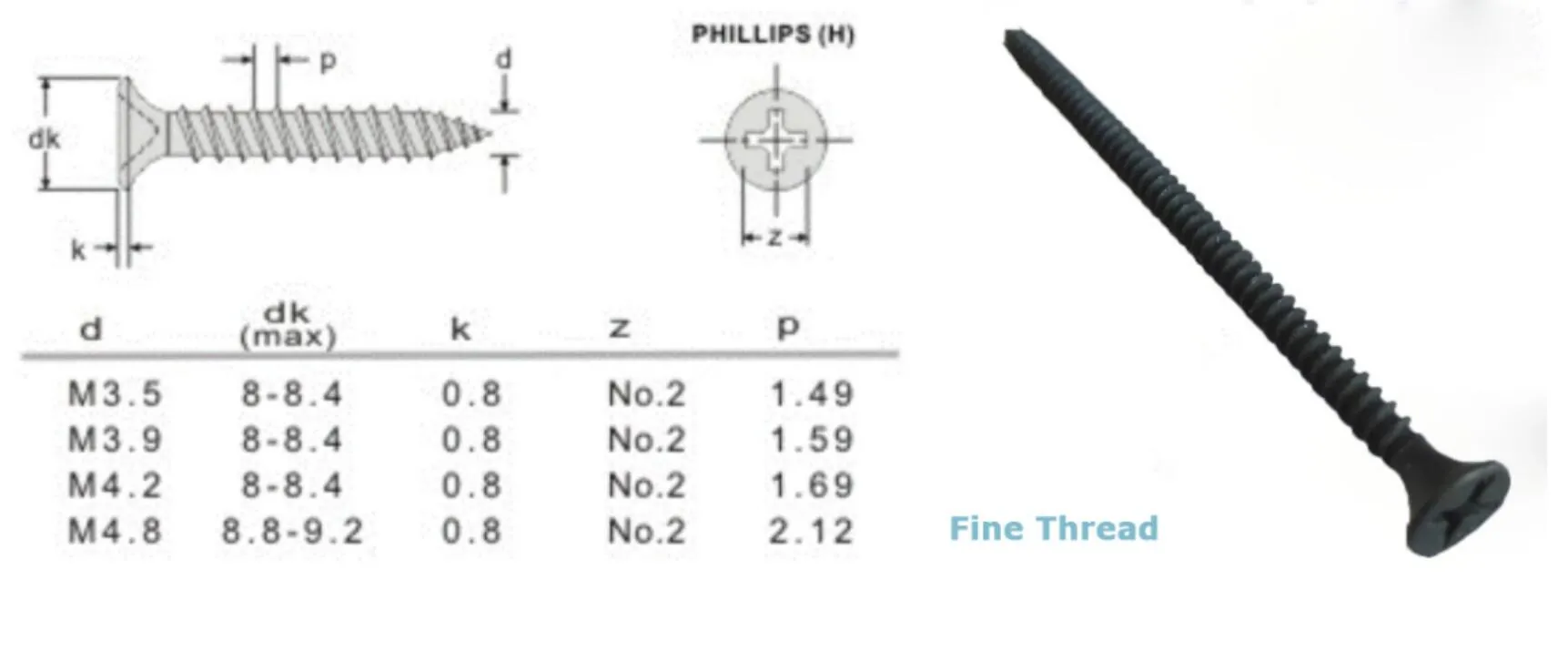

no 8 self tapping screw dimensions

The no. 8 self-tapping screw, a cornerstone in fastening, has continuously proven its worth across various industries—be it construction, automotive, or home DIY projects. The effectiveness of this screw type largely hinges on the precise understanding of its dimensions and application. With the quest for reliable fastening solutions becoming paramount, grasping the layout of these screws becomes indispensable.

Moreover, material composition of the no. 8 screw further dictates its suitability for specific environments. Stainless steel screws are revered for their corrosion resistance and strength, making them ideal for outdoor applications or projects exposed to moisture. Carbon steel screws, often coated with zinc or other treatments, offer a balance of cost-effectiveness and durability unmatched in less demanding environments. In practice, using no. 8 self-tapping screws significantly hinges on optimizing dimensions relative to material and application constraints. Accuracy in selecting the right screw length, thread pitch, and head style maximizes structural integrity and project outcomes. Where precision is paramount, these screws serve a dual purpose of offering robust performance and aesthetic appeal. Further authenticity to their application lies in real-life experiences and expert recommendations. One instance is detailed feedback from a seasoned woodworker recounting the ease with which a 1 1/4 inch no. 8 self-tapping screw allowed for the effortless assembly of a wooden frame—demonstrating effectiveness even without pilot holes due to the intelligent design of the screw's thread and pitch. Similarly, industry experts consistently advocate for the selection of the correct no. 8 self-tapping screw variant with regard to the material and environment. They emphasize that neglecting these factors could lead to potential failures in structural integrity, especially where load-bearing is critical. Comprehensive guides and standards in the sector, such as those from the American Society of Mechanical Engineers (ASME), further detail dimensional criteria aligning with specific applications, offering a blueprint for achieving excellence in construction and assembly processes. In conclusion, the no. 8 self-tapping screw's dimensions serve as a foundation for successful fastening solutions. Equipped with precise knowledge of dimensions and able to draw on expert advice and authoritative guidelines, practitioners from various fields can ensure that their applications thrive, ultimately safeguarding both aesthetic and structural intentions.

Moreover, material composition of the no. 8 screw further dictates its suitability for specific environments. Stainless steel screws are revered for their corrosion resistance and strength, making them ideal for outdoor applications or projects exposed to moisture. Carbon steel screws, often coated with zinc or other treatments, offer a balance of cost-effectiveness and durability unmatched in less demanding environments. In practice, using no. 8 self-tapping screws significantly hinges on optimizing dimensions relative to material and application constraints. Accuracy in selecting the right screw length, thread pitch, and head style maximizes structural integrity and project outcomes. Where precision is paramount, these screws serve a dual purpose of offering robust performance and aesthetic appeal. Further authenticity to their application lies in real-life experiences and expert recommendations. One instance is detailed feedback from a seasoned woodworker recounting the ease with which a 1 1/4 inch no. 8 self-tapping screw allowed for the effortless assembly of a wooden frame—demonstrating effectiveness even without pilot holes due to the intelligent design of the screw's thread and pitch. Similarly, industry experts consistently advocate for the selection of the correct no. 8 self-tapping screw variant with regard to the material and environment. They emphasize that neglecting these factors could lead to potential failures in structural integrity, especially where load-bearing is critical. Comprehensive guides and standards in the sector, such as those from the American Society of Mechanical Engineers (ASME), further detail dimensional criteria aligning with specific applications, offering a blueprint for achieving excellence in construction and assembly processes. In conclusion, the no. 8 self-tapping screw's dimensions serve as a foundation for successful fastening solutions. Equipped with precise knowledge of dimensions and able to draw on expert advice and authoritative guidelines, practitioners from various fields can ensure that their applications thrive, ultimately safeguarding both aesthetic and structural intentions.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News