high quality 10-32 self tapping machine screw

The Importance of High-Quality Self-Tapping Machine Screws

In the realm of fasteners and hardware, self-tapping machine screws play a pivotal role in construction, manufacturing, and DIY projects. These screws are designed to create their own mating thread when driven into a material, eliminating the need for a pre-drilled hole. However, not all self-tapping screws are created equal. The importance of high-quality self-tapping machine screws cannot be overstated, especially when it comes to ensuring structural integrity, ease of use, and long-term reliability.

Understanding Self-Tapping Screws

Self-tapping screws are available in various types, materials, and sizes, each suited for specific applications. They can be used with a vast array of materials, including metal, wood, and plastic. The unique design of these screws allows them to cut through the substrate, forming a tight and secure joint. This feature is particularly advantageous in situations where traditional screws would require additional threading or pre-drilling, thus saving time and effort during assembly or installation.

Quality Matters

When considering self-tapping screws for a project, quality should be a primary concern. High-quality screws typically feature superior materials, such as carbon steel or stainless steel, which provide enhanced strength and corrosion resistance. These materials ensure that the screws can withstand environmental factors and mechanical stress over time. In contrast, low-quality screws may be prone to bending, breaking, or stripping, leading to potential failures in the structures they are used to secure.

high quality 10-32 self tapping machine screw

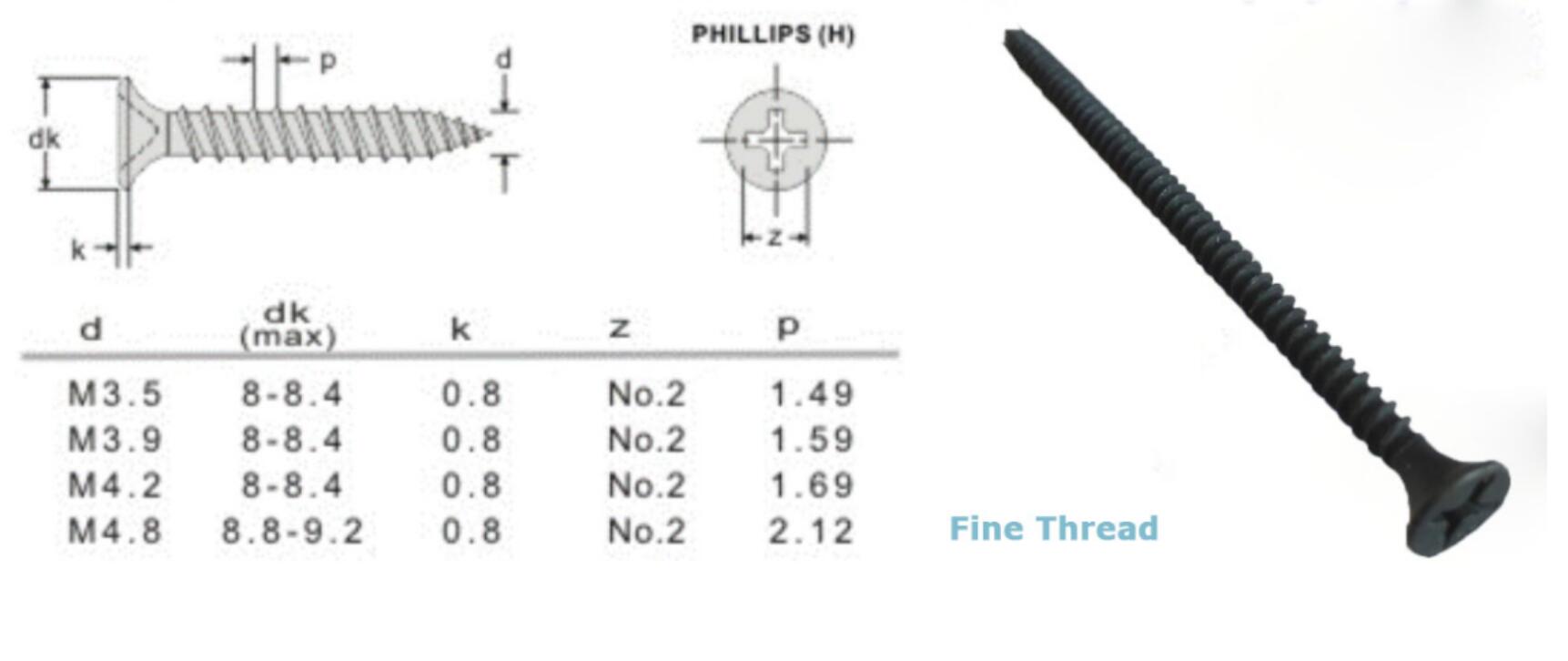

Another critical aspect of high-quality self-tapping screws is their precise manufacturing standards. High-quality screws undergo rigorous quality control processes to ensure consistent sizing, threading accuracy, and proper surface treatment. This precision not only improves the ease of driving the screw but also enhances the overall performance of the fastened joint. Screws that are poorly manufactured can cause issues such as partial threading, which compromises the strength of the connection.

Applications and Advantages

High-quality self-tapping machine screws are versatile and can be utilized in various applications, ranging from construction and automotive to electronics and furniture manufacturing. Their ability to create a secure connection without pre-drilling makes them a favored choice among professionals and hobbyists alike. The efficiency gained from using self-tapping screws can significantly reduce labor costs and project timelines, making them an economical choice in many cases.

Moreover, the use of high-quality screws can yield additional benefits, such as reducing the risk of damage to the materials being fastened. When inferior screws are driven into materials, there is an increased likelihood of splitting or cracking, particularly in fragile substrates like hardwood or thin metal sheets. High-quality screws minimize this risk, providing peace of mind and a more aesthetically pleasing finish to the project.

Conclusion

In conclusion, the significance of high-quality self-tapping machine screws cannot be overlooked. Their ability to provide strong, dependable connections in a variety of materials, coupled with their ease of use, makes them indispensable in many fields. By opting for high-quality screws, users can enhance the overall durability and safety of their projects, ensuring that they stand the test of time. Whether you are a professional tradesperson or a DIY enthusiast, investing in top-tier self-tapping screws is a decision that will pay dividends in performance and reliability.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024