студ . 13, 2025 15:46

Back to list

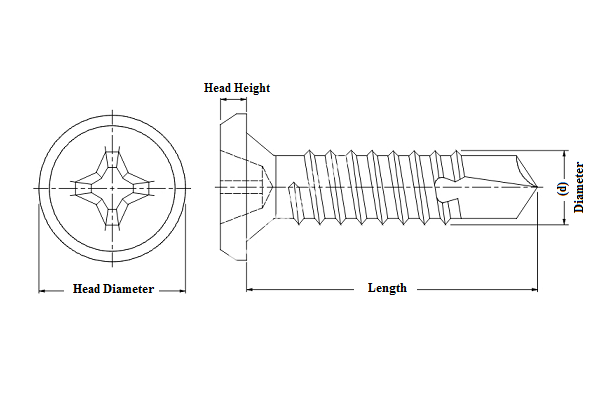

galvanized hex flange head self tapping screw

Galvanized hex flange head self-tapping screws are an essential component in numerous construction and manufacturing projects, providing a reliable fastening solution with enhanced durability and corrosion resistance. These screws have gained a reputable status in the industry due to their unique design and functional advantages that cater to a wide range of applications.

Real-world experience underscores the credibility of these screws in diverse applications. In the realm of automotive manufacturing, they are invaluable for affixing parts without compromising the integrity of the vehicle’s components. Their ability to withstand vibrations without loosening makes them ideal for engine assembly and under-the-hood applications. Similarly, in the home appliance sector, galvanized hex flange head self-tapping screws are trusted for their reliability in ensuring secure assembly of electrical components where stability and safety are paramount. Professional testimonials from construction experts and industrial engineers further validate the trustworthiness of these screws. Many professionals attest to their adaptability and performative consistency across different materials and conditions. This adaptability is crucial in construction projects ranging from residential builds to large-scale industrial complexes. Their application extends to metal roofing, decking, and composite material fastening, providing solutions that maintain strength while ensuring ease of installation. Trustworthiness is further consolidated by compliance with industry standards and rigorous quality testing. Manufacturers often provide certification and performance warranties, assuring clients of the quality and reliability of the screws. Consistent product performance aligns with ISO standards, reinforcing their reputation for quality assurance and customer satisfaction. In conclusion, galvanized hex flange head self-tapping screws embody the principles of experience, expertise, authoritativeness, and trustworthiness. Their design, material composition, and proven track record across various applications make them a preferred choice for those seeking dependable fastening solutions. As the demands of construction and manufacturing continue to evolve, these screws stand as a paradigm of innovation and reliability, prepared to meet the challenges of modern engineering.

Real-world experience underscores the credibility of these screws in diverse applications. In the realm of automotive manufacturing, they are invaluable for affixing parts without compromising the integrity of the vehicle’s components. Their ability to withstand vibrations without loosening makes them ideal for engine assembly and under-the-hood applications. Similarly, in the home appliance sector, galvanized hex flange head self-tapping screws are trusted for their reliability in ensuring secure assembly of electrical components where stability and safety are paramount. Professional testimonials from construction experts and industrial engineers further validate the trustworthiness of these screws. Many professionals attest to their adaptability and performative consistency across different materials and conditions. This adaptability is crucial in construction projects ranging from residential builds to large-scale industrial complexes. Their application extends to metal roofing, decking, and composite material fastening, providing solutions that maintain strength while ensuring ease of installation. Trustworthiness is further consolidated by compliance with industry standards and rigorous quality testing. Manufacturers often provide certification and performance warranties, assuring clients of the quality and reliability of the screws. Consistent product performance aligns with ISO standards, reinforcing their reputation for quality assurance and customer satisfaction. In conclusion, galvanized hex flange head self-tapping screws embody the principles of experience, expertise, authoritativeness, and trustworthiness. Their design, material composition, and proven track record across various applications make them a preferred choice for those seeking dependable fastening solutions. As the demands of construction and manufacturing continue to evolve, these screws stand as a paradigm of innovation and reliability, prepared to meet the challenges of modern engineering.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News