flat cut washer manufacturer

Flat Cut Washer Manufacturer Understanding the Importance, Applications, and Manufacturing Process

In the world of engineering and construction, the importance of components that ensure safety and stability cannot be understated. Among these essential components are flat cut washers, which play a vital role in various applications, from automotive to aerospace, and everything in between. A flat cut washer manufacturer specializes in producing these critical components, ensuring high quality and precise dimensions to meet various industrial standards.

What are Flat Cut Washers?

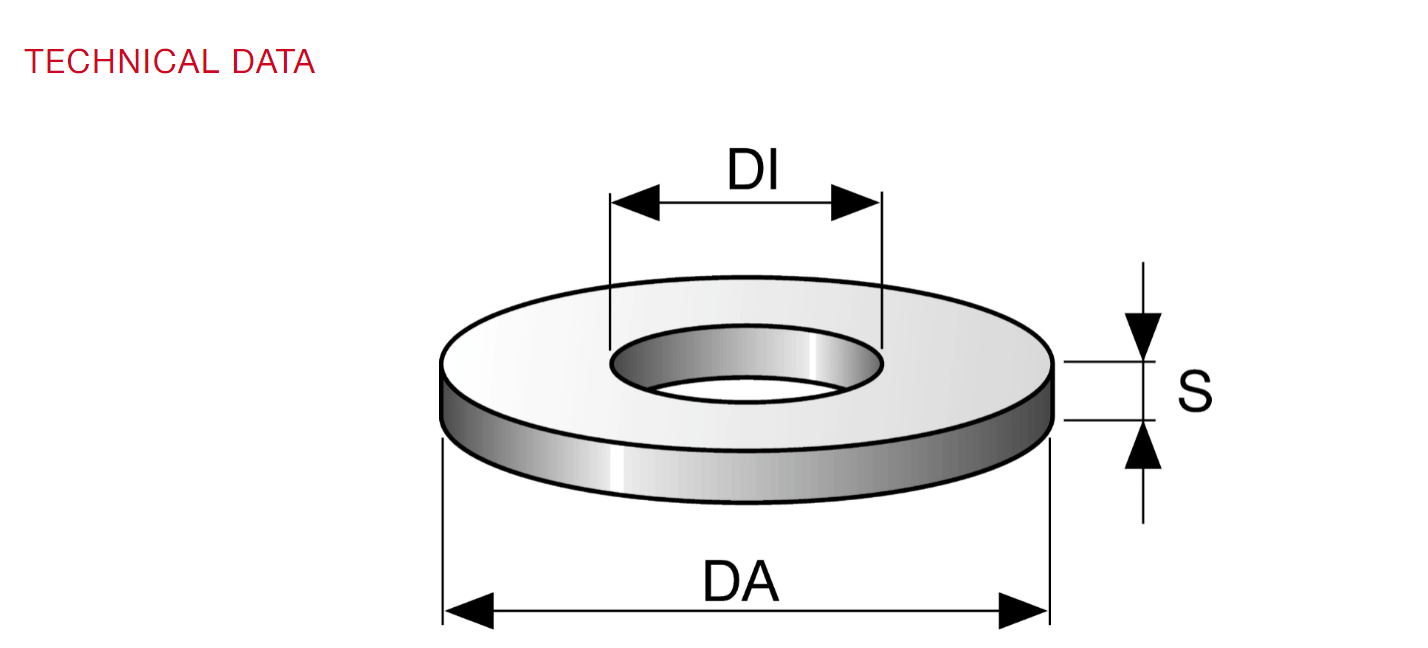

Flat cut washers are thin, flat discs made of various materials, such as metal, plastic, or rubber. They are designed to distribute load, reduce friction, and prevent damage to parts being fastened. Washers help to create a secure fit when bolts or screws are used, offering a larger surface area to bear the load and protect the material being fastened from wear. They can also act as spacers, shims, or seals, which are essential in certain applications to enhance performance and longevity.

Importance in Various Industries

1. Automotive Industry In vehicles, flat washers are critical in various assemblies, such as engine mounts, suspension systems, and exhaust components. They help maintain tight seals, absorb vibrations, and prevent loosening due to dynamic forces. 2. Construction and Structural Engineering Flat cut washers provide stability in construction projects. They are used in securing beams, columns, and other structural elements, ensuring safety and compliance with building codes.

3. Aerospace In the aerospace sector, where precision is paramount, flat washers are used in aircraft assemblies. They must withstand extreme conditions, including high pressure and temperature fluctuations.

4. Electronics In electronics, washers are used to minimize the risk of shorts and enhance the performance of electronic components. They help maintain proper spacing and prevent physical wear over time.

Manufacturing Process

The manufacturing of flat cut washers involves several key steps

flat cut washer manufacturer

1. Material Selection High-quality materials such as stainless steel, brass, aluminum, and various plastics are chosen based on the specific application requirements. Factors such as strength, corrosion resistance, and thermal stability are considered during this phase.

2. Cutting The selected material is cut into flat discs using precision cutting machinery. Laser cutting and stamping are common methods that allow for high accuracy and low tolerances.

3. Finishing After cutting, the washers undergo various finishing processes. This could include deburring to remove sharp edges, surface treatment like anodizing or galvanizing for corrosion resistance, and polishing for aesthetic purposes.

4. Quality Control Each batch of flat cut washers is rigorously tested to ensure they meet stringent quality standards. This includes checking the dimensions, surface finish, and material properties. Manufacturers often employ automated inspection techniques to enhance reliability.

5. Packaging and Distribution Once the washers pass quality checks, they are packaged and prepared for distribution. Many manufacturers offer customization options to meet specific client needs, including varying sizes, materials, and finishes.

Customization and Compliance

One of the significant advantages of working with a flat cut washer manufacturer is the ability to obtain customized products. Depending on the industry’s specific requirements, manufacturers can create washers that meet unique specifications, including size, thickness, and material composition.

Moreover, compliance with industry standards such as ISO, ASTM, and ASME is crucial. A reputable manufacturer will ensure their products meet these standards, which guarantees reliability and safety in their applications.

Conclusion

Flat cut washers may appear to be simple components, but their role in various industries is critical. As we have explored, they contribute significantly to the functionality and safety of countless products and systems. Partnering with a competent flat cut washer manufacturer ensures that you receive high-quality, reliable components tailored to your specific needs. Whether in automotive applications, construction, aerospace, or electronics, flat washers are a small part of a larger puzzle, but one that should never be overlooked. Investing in quality washers now can pay dividends in performance and safety long into the future.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024