лют . 01, 2025 03:37

Back to list

5/8 drywall screw length

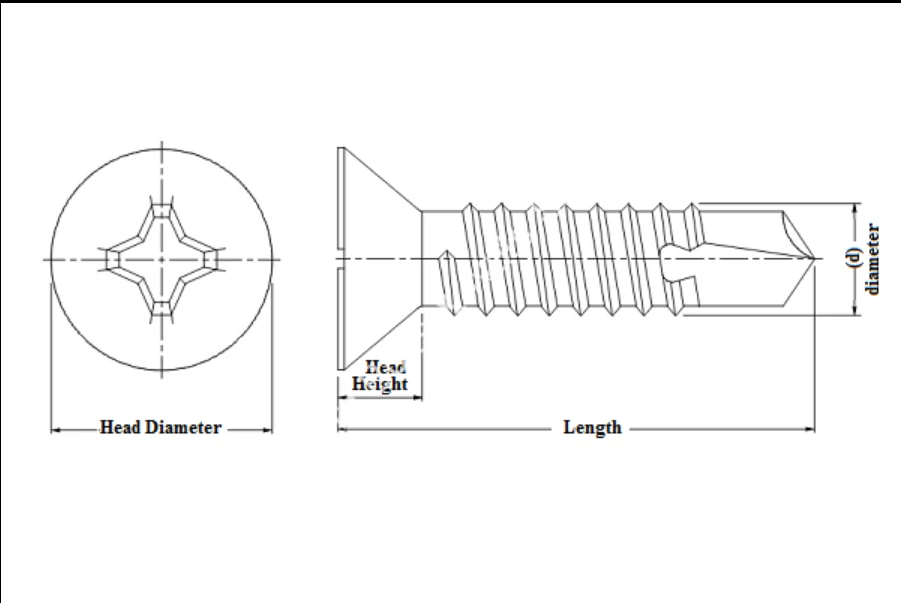

Understanding the optimal drywall screw head diameter is essential for both professional builders and DIY enthusiasts. Choosing the correct size not only influences the structural integrity of the project but also impacts the aesthetic finish and the ease of installation. In this guide, we delve into the nuances of drywall screw head diameter, drawing from professional insights and authoritative practices to provide a comprehensive understanding.

Trustworthiness in drywall installation not only comes from using the correct materials but also from adhering to industry recommendations and expert-backed practices. The National Building Codes provide guidance on appropriate material specifications, including screw dimensions, that ensure safety and durability without compromising on aesthetics. As the construction industry evolves, technological advancements continually refine our understanding of materials science. Professionals increasingly utilize tools like drywall screw guns with adjustable depth settings to maintain consistency in screw placement and depth, simultaneously preserving the integrity of the drywall and the underlying structure. In terms of authoritativeness, manufacturers and industry leaders often provide specific recommendations for screw head sizes tailored to their own products. Consulting these resources ensures compatibility and optimal results. Furthermore, authoritative bodies often conduct and publish test results that confirm the efficacy of varying screw head diameters under different conditions, providing evidence-based recommendations for best practices. For first-time users or less experienced DIY enthusiasts, establishing trust in your materials begins with understanding the fundamental components, such as screw head diameter. Consider reaching out to professional contractors or engaging with community forums dedicated to construction for real-world advice and anecdotal experiences. Doing so can provide invaluable insights into potential pitfalls and recommended solutions, encouraging successful outcomes for both novice and seasoned builders alike. In conclusion, the drywall screw head diameter is more than just a measurement; it embodies structural wisdom and aesthetic consideration. Selection should be guided by the specific needs of your project, keeping in mind environmental conditions, drywall type, and finishing requirements. By leveraging expert insights and adhering to authoritative guidelines, builders can achieve durable, visually appealing results that stand the test of time.

Trustworthiness in drywall installation not only comes from using the correct materials but also from adhering to industry recommendations and expert-backed practices. The National Building Codes provide guidance on appropriate material specifications, including screw dimensions, that ensure safety and durability without compromising on aesthetics. As the construction industry evolves, technological advancements continually refine our understanding of materials science. Professionals increasingly utilize tools like drywall screw guns with adjustable depth settings to maintain consistency in screw placement and depth, simultaneously preserving the integrity of the drywall and the underlying structure. In terms of authoritativeness, manufacturers and industry leaders often provide specific recommendations for screw head sizes tailored to their own products. Consulting these resources ensures compatibility and optimal results. Furthermore, authoritative bodies often conduct and publish test results that confirm the efficacy of varying screw head diameters under different conditions, providing evidence-based recommendations for best practices. For first-time users or less experienced DIY enthusiasts, establishing trust in your materials begins with understanding the fundamental components, such as screw head diameter. Consider reaching out to professional contractors or engaging with community forums dedicated to construction for real-world advice and anecdotal experiences. Doing so can provide invaluable insights into potential pitfalls and recommended solutions, encouraging successful outcomes for both novice and seasoned builders alike. In conclusion, the drywall screw head diameter is more than just a measurement; it embodies structural wisdom and aesthetic consideration. Selection should be guided by the specific needs of your project, keeping in mind environmental conditions, drywall type, and finishing requirements. By leveraging expert insights and adhering to authoritative guidelines, builders can achieve durable, visually appealing results that stand the test of time.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News