студ . 13, 2025 16:32

Back to list

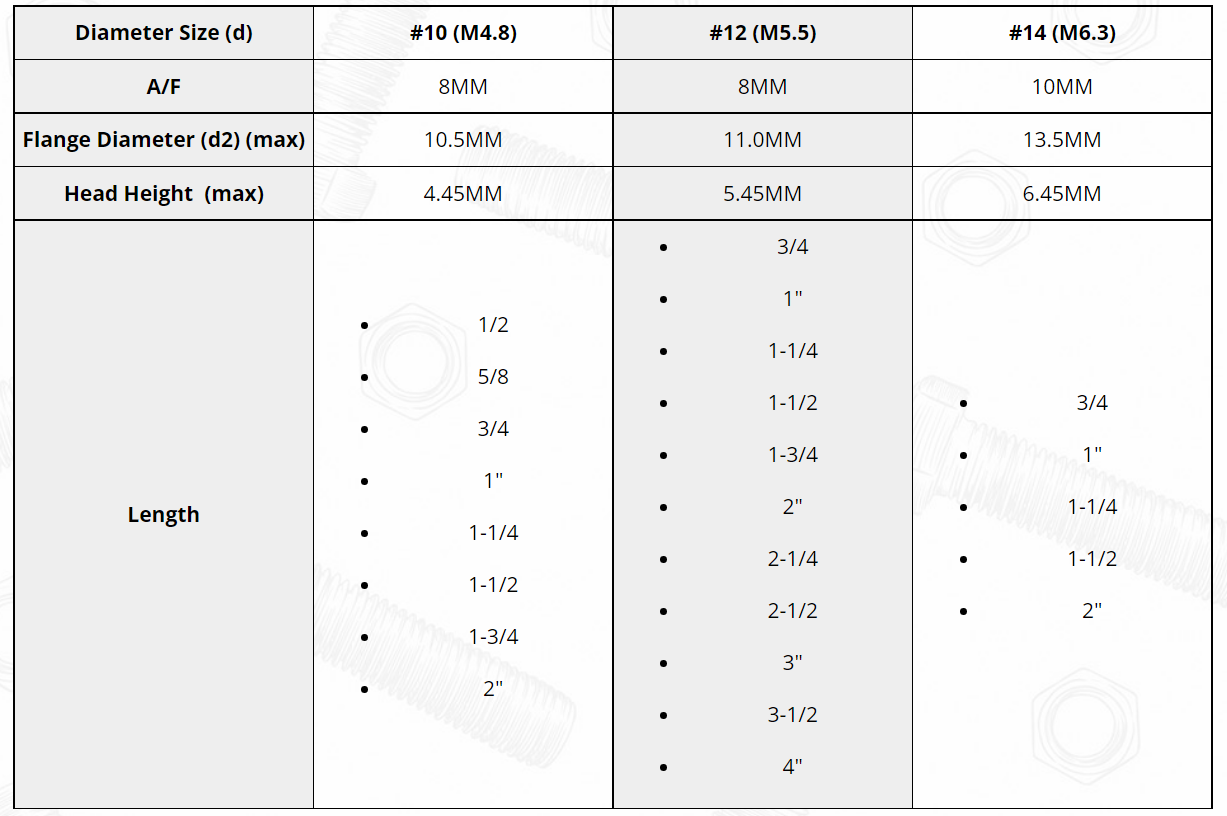

Double flat head with Nibs under head self drilling screws

The galvanized truss head self-tapping screw plays an indispensable role in construction and manufacturing due to its robust design and exceptional functionality. With the increasing demand for durable and efficient fastening solutions, understanding the characteristics, applications, and advantages of these screws is essential for professionals in the field.

When it comes to performance, the galvanized truss head self-tapping screws excel in various applications. They are widely used in construction, automotive industries, home improvement projects, and in the assembly of electronic devices. Their reliability in holding components together makes them a preferred choice for professionals seeking durability and peace of mind. In construction, they are often used in metal and wood framing, roofing, and cladding applications. Their corrosion resistance makes them ideal for exterior projects exposed to the elements, maintaining structural integrity over time. Expert advice emphasizes the importance of selecting the right size and type of screw for specific applications. Professionals recommend assessing the thickness and type of material, environmental factors, and the mechanical load the fastening will bear. This ensures the screws are not only appropriate for the job but also perform at their optimal capacity, reducing the risk of failure and subsequent repair needs. For those who prioritize credibility, sourcing these screws from reputable manufacturers is crucial. Companies with a track record of producing high-quality fasteners guarantee products that meet industry standards. Certifications and adherence to quality control measures further enhance trust, ensuring that the screws deliver as promised and provide durability in even the most demanding applications. In conclusion, galvanized truss head self-tapping screws represent a fusion of innovation and practicality in the world of fasteners. Their corrosion resistance, combined with the effective truss head design and self-tapping capabilities, makes them indispensable for professionals seeking reliable and efficient fastening methods. As industries continue to evolve, the demand for such high-performance solutions will undoubtedly grow, underscoring the importance of understanding their benefits and applications. By adhering to best practices and relying on expert recommendations, users can maximize the potential of these remarkable screws, ensuring their projects are built to last.

When it comes to performance, the galvanized truss head self-tapping screws excel in various applications. They are widely used in construction, automotive industries, home improvement projects, and in the assembly of electronic devices. Their reliability in holding components together makes them a preferred choice for professionals seeking durability and peace of mind. In construction, they are often used in metal and wood framing, roofing, and cladding applications. Their corrosion resistance makes them ideal for exterior projects exposed to the elements, maintaining structural integrity over time. Expert advice emphasizes the importance of selecting the right size and type of screw for specific applications. Professionals recommend assessing the thickness and type of material, environmental factors, and the mechanical load the fastening will bear. This ensures the screws are not only appropriate for the job but also perform at their optimal capacity, reducing the risk of failure and subsequent repair needs. For those who prioritize credibility, sourcing these screws from reputable manufacturers is crucial. Companies with a track record of producing high-quality fasteners guarantee products that meet industry standards. Certifications and adherence to quality control measures further enhance trust, ensuring that the screws deliver as promised and provide durability in even the most demanding applications. In conclusion, galvanized truss head self-tapping screws represent a fusion of innovation and practicality in the world of fasteners. Their corrosion resistance, combined with the effective truss head design and self-tapping capabilities, makes them indispensable for professionals seeking reliable and efficient fastening methods. As industries continue to evolve, the demand for such high-performance solutions will undoubtedly grow, underscoring the importance of understanding their benefits and applications. By adhering to best practices and relying on expert recommendations, users can maximize the potential of these remarkable screws, ensuring their projects are built to last.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News