Discounts on Self Tapping Screws 2012 to 2024 for Your Projects and Repairs

Exploring the Benefits and Applications of Discount Self-Tapping Screws 2012 to 2024

Self-tapping screws have become an essential component in various industries, providing durability and efficiency in fastening applications. As we delve into the period from 2012 to 2024, we will explore the evolution of self-tapping screws, focusing on the benefits of discounts and contemporary innovations in this ubiquitous hardware.

Understanding Self-Tapping Screws

Self-tapping screws are designed to create their own hole as they are driven into materials, eliminating the need for pre-drilling. This characteristic makes them incredibly convenient for various applications, particularly in construction, automotive, and electronics. Over the years, they have evolved in terms of design, materials, and ease of use, adapting to the ever-changing needs of industries.

The Financial Advantage of Discounts

The availability of discounted self-tapping screws has significantly impacted purchasing decisions for businesses and DIY enthusiasts alike. Over the past decade, from 2012 to 2024, numerous suppliers have recognized the demand for affordable quality during economic fluctuations. Discounts not only make these essential tools more accessible but also support bulk purchasing, which can lead to substantial savings for contractors and manufacturers.

For example, buying in bulk often unlocks deeper discounts and promotes more efficient project budgeting. As projects grow in scope and complexity, having access to competitively priced self-tapping screws ensures that projects can stay on track without unexpected overages in hardware costs.

Innovations in Self-Tapping Screws

The period from 2012 to 2024 has also seen significant technological advancements that have enhanced the performance of self-tapping screws. Manufacturers have incorporated various materials and coatings, resulting in products that offer improved corrosion resistance, strength, and ease of use.

discount 12 24 self tapping screw

1. Materials Advancement The introduction of stainless steel and specialized alloys has increased the toughness of self-tapping screws, enabling them to withstand harsh environments, such as coastal areas with saltwater exposure or industrial settings with extreme temperatures.

2. Coatings Modern self-tapping screws now feature advanced coatings, such as zinc plating or polymer finishes, which enhance corrosion resistance. These innovations help prolong the life of screws, minimizing replacement costs over time.

3. Design Features Innovative designs, such as bugle heads and sharp, self-drilling tips, have improved the versatility of self-tapping screws. These features allow for a more secure fit in various materials, including metal, wood, and plastic, appealing to a wider range of applications.

Applications Across Industries

The versatility of self-tapping screws has made them suitable for numerous applications. In the construction industry, they are commonly used for framing, securing drywall, and fastening structural elements. In automotive manufacturing, self-tapping screws provide reliability in assembly processes. Additionally, electronic devices increasingly utilize these screws for their lightweight design and ease of integration.

The DIY community has also embraced self-tapping screws for home improvement projects ranging from furniture assembly to outdoor constructions like decks and fences, highlighting the importance of accessibility provided by discount offerings.

Conclusion

From 2012 to 2024, self-tapping screws have seen remarkable progress both in technological advancements and accessibility through discounts. These developments not only enhance the functionality of the screws but also make them more affordable and attractive in various applications. As industries continue to innovate and adapt, self-tapping screws will undoubtedly remain a cornerstone of construction and manufacturing processes, affirming their value in both professional and personal projects. As we look forward to the future, the blend of quality, price, and innovation will continue to shape the landscape of fastening solutions, ensuring that this indispensable component is readily available for all users.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

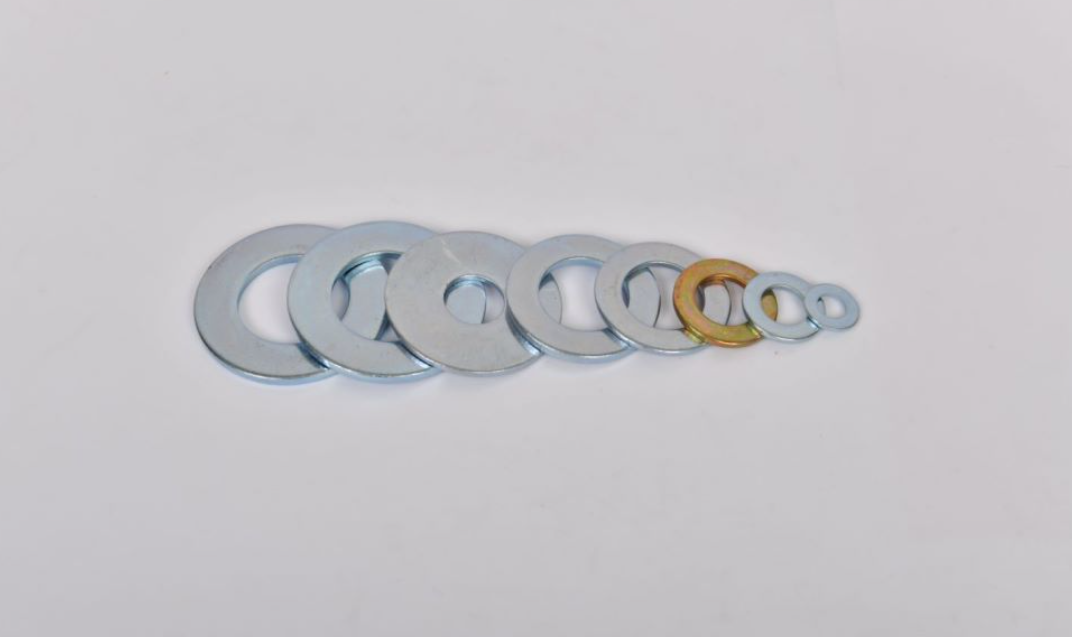

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024