Custom Washer and Spring Washer Manufacturing and Ordering Solutions

The Importance of Custom Washers and Spring Washers in Mechanical Design

In the realm of mechanical design and engineering, the components we often take for granted play a crucial role in the functionality and durability of machines. Among these components, washers—specifically custom washers and spring washers—are fundamental elements that serve diverse purposes. Understanding their significance can lead to improved design solutions and enhanced performance in various applications.

What Are Custom Washers?

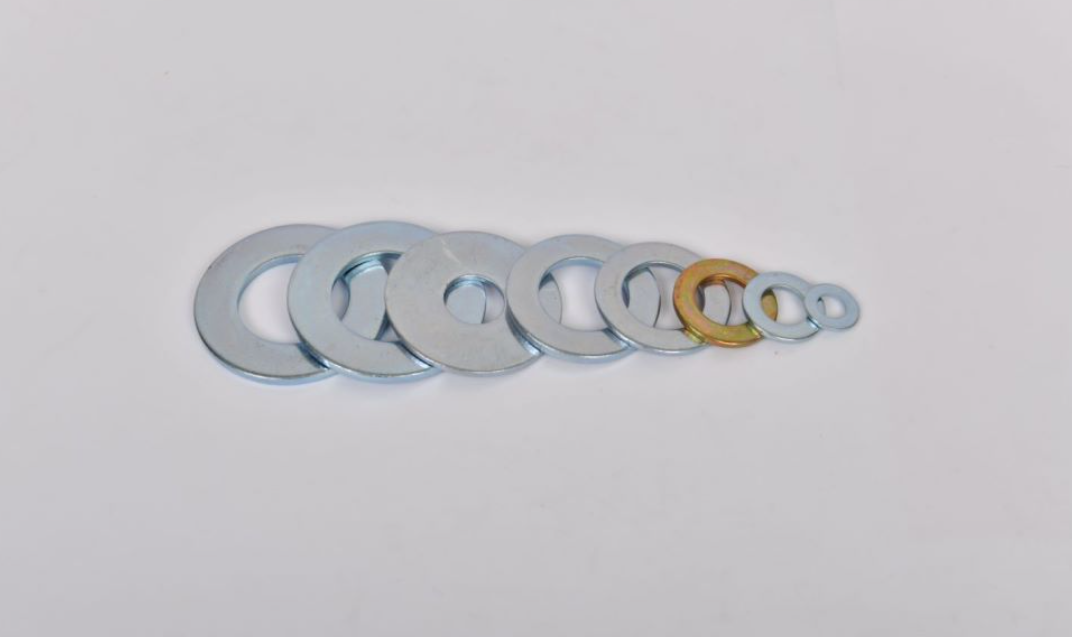

Custom washers are tailored specifically to meet the unique requirements of a particular application. Unlike standard washers that come in predefined sizes and materials, custom washers are designed based on factors such as the dimensions of the bolts or screws they accompany, the load they will bear, and the operational conditions they will face, including temperature, pressure, and exposure to chemicals.

Custom washers can be made from various materials, including steel, stainless steel, plastic, and rubber. Each material offers distinct advantages. For instance, stainless steel is ideal for high-corrosion environments, while rubber washers provide excellent vibration dampening and sealing capabilities. This versatility allows engineers to develop solutions optimized for their specific use cases, enhancing reliability and performance.

The Role of Spring Washers

Spring washers, often referred to as toothed washers or lock washers, are designed to prevent loosening due to vibrations and dynamic loads. They work by exerting a spring force that keeps the bolt or nut tight. The unique shape of spring washers allows them to compress and expand, absorbing shock and reducing the likelihood of fasteners becoming loose over time.

These washers are commonly used in applications where regular mechanical stress occurs, such as in machinery, automotive components, and construction equipment. Their effectiveness at maintaining tension in screwed joints makes them vital for ensuring the integrity of assemblies subjected to movement and vibration.

Benefits of Custom Washers and Spring Washers

custom washer and spring washer order

1. Enhanced Performance Custom washers are tailored for specific applications, which ensures optimal load distribution and improves overall performance. This customization can prevent failures and prolong the lifespan of components.

2. Improved Efficiency By utilizing spring washers in dynamic applications, designers can reduce maintenance costs associated with loosening fasteners. This efficiency translates to less downtime and greater productivity in operations.

3. Cost-Effectiveness While custom components may appear more expensive upfront, their long-term benefits often outweigh initial costs. Custom washers can mitigate the risks of catastrophic failures, reducing the need for expensive repairs and replacements.

4. Customization Engineers can specify the exact diameter, thickness, and material of custom washers to fit their requirements precisely. This level of customization is especially important in specialized industries, such as aerospace and automotive.

5. Safety Assurance In critical applications, ensuring that parts remain securely fastened can be a matter of safety. Custom and spring washers provide the necessary confidence that bolted joints will remain intact under stress.

Conclusion

The significance of custom washers and spring washers in mechanical design cannot be overstated. As the complexity of engineering solutions increases, the importance of these small yet mighty components becomes even more pronounced. By investing in tailored solutions, engineers can not only enhance the functionality and reliability of their designs but also ensure safety and efficiency in countless applications.

In a world where precision and performance are paramount, understanding the role of custom washers and spring washers is essential. Whether in automotive assembly lines, heavy machinery, or delicate electronic devices, these seemingly simple components are integral to the successful operation of modern technology. By prioritizing quality and customization in washer orders, designers and manufacturers can pave the way for better products and systems that stand the test of time.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024