custom drywall screw length for 5/8

Understanding Custom Drywall Screw Lengths for 5/8 Drywall

When it comes to drywall installation, selecting the right materials and tools is crucial for a successful and long-lasting finish. One of the most important components in this process is the drywall screw. Among the various factors to consider, screw length is of utmost importance, especially when working with 5/8 drywall. This article will delve into the significance of custom drywall screw lengths for 5/8 drywall, examining their applications, benefits, and best practices.

The Basics of Drywall Thickness

Drywall comes in various thicknesses, with 1/2 and 5/8 being the most common. The choice of thickness typically depends on the intended application. Walls and ceilings that require more durability, sound resistance, or fire resistance often use 5/8 drywall. This thicker material necessitates the use of appropriately sized screws to ensure a secure installation.

The Importance of Screw Length

When installing drywall, the length of the screw is vital for several reasons

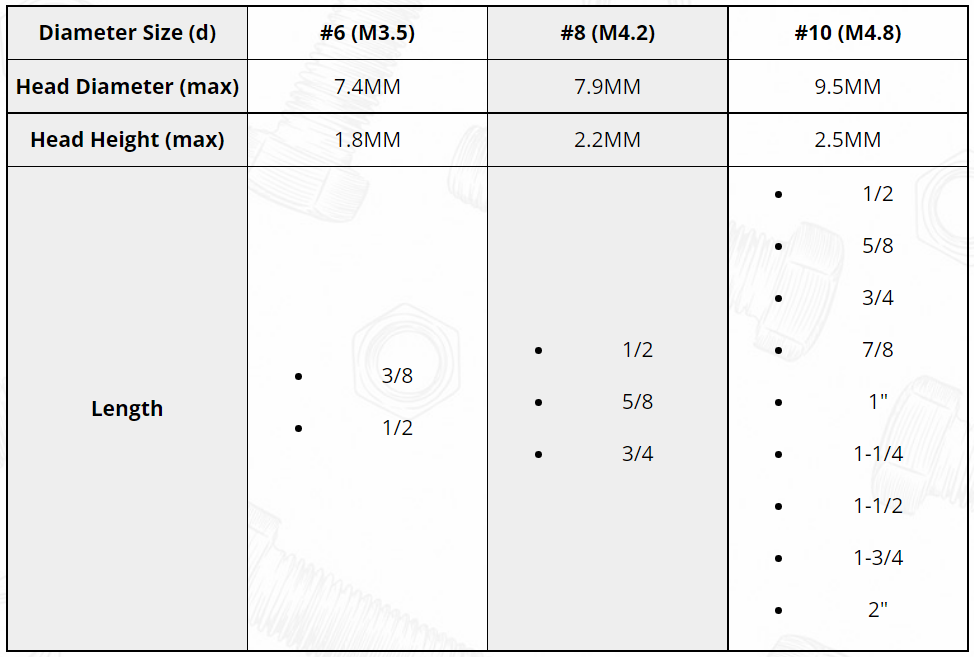

1. Holding Power The screw needs to penetrate deeply enough into the underlying stud or framework. For 5/8 drywall, a standard screw length is typically around 1 1/4 to 1 5/8. These lengths provide enough penetration to hold the drywall securely while minimizing the risk of the screw coming loose over time.

2. Avoiding Damage If a screw is too long, it can protrude through the back of the drywall, potentially causing damage to electrical wiring or plumbing that may be installed behind the walls. Custom lengths can help mitigate this risk, ensuring that screws perform effectively without any unintended consequences.

3. Surface Finish Using the correct screw length contributes to a better surface finish. Screws that are set too deep can create dimples that require extensive filling and sanding, while screws that are not deep enough may not hold the drywall securely, leading to future issues.

Custom Screw Lengths Why Personalization Matters

While there are standard screw lengths available, sometimes custom lengths are necessary. Here are some scenarios where custom drywall screws come into play

custom drywall screw length for 5/8

1. Unique Applications In some construction projects, there may be specific requirements based on the design or materials used. For example, if additional layers of drywall are needed for soundproofing or fire resistance, custom lengths can ensure that all layers are secured correctly.

2. Variable Wall or Ceiling Height In cases where walls or ceilings are higher than average, or if the type of framing is non-standard, custom screw lengths can be tailored to fit perfectly, holding the drywall without compromising structural integrity.

3. Compatibility with Other Materials If you're working with different materials, such as plywood or metal studs, the length and type of screw may vary. Custom screws can be designed to ensure compatibility with various substrates.

Best Practices for Installing 5/8 Drywall

To ensure the best results when installing 5/8 drywall with the appropriate screw lengths

1. Choose the Right Screw Use screws specifically designed for drywall. These screws typically feature a bugle head and sharp tips to make installation easier.

2. Measure Carefully Before installation, measure the thickness of the drywall and the framing material to determine the ideal screw length.

3. Use a Screw Gun An automatic screw gun can help achieve consistent screw depths, ensuring that all screws are driven to the correct level and improving overall efficiency.

4. Check Local Codes Be aware of any local building codes or regulations regarding drywall installation, as these may dictate specific requirements for screw lengths and spacing.

In conclusion, choosing the right length of drywall screws is a critical step in the successful installation of 5/8 drywall. While standard lengths are often adequate, custom lengths can provide a tailored solution to meet specific project needs. By considering factors such as holding power, surface finish, and compatibility with different materials, professionals and DIY enthusiasts alike can ensure a durable, high-quality result that stands the test of time.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024