conical disc spring washer company

Understanding Conical Disc Spring Washers A Solution for Enhanced Load Distribution

In the vast world of mechanical components, the conical disc spring washer stands out for its unique design and effective performance. Often used in various applications, these washers provide exceptional load distribution and flexibility, making them a preferred choice in numerous industries ranging from automotive to aerospace.

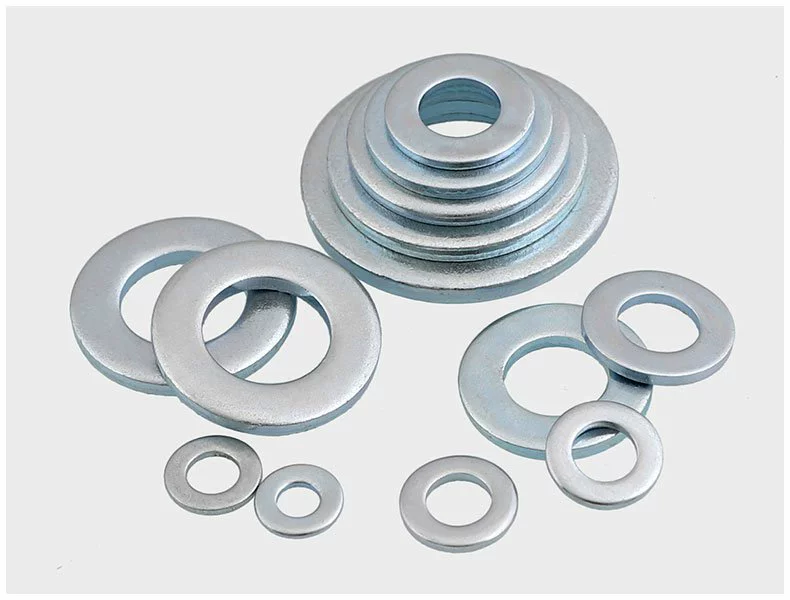

What Is a Conical Disc Spring Washer?

A conical disc spring washer is a type of spring washer characterized by its conical shape. This design allows the washer to act like a spring, providing not only load support but also the ability to absorb shocks and vibrations. The washer is typically made from high-strength materials such as stainless steel or carbon steel, ensuring durability and long-lasting performance under various loads and environmental conditions.

Advantages of Using Conical Disc Spring Washers

1. Load Distribution The conical shape of the washer enables it to distribute loads evenly across a surface, reducing the risk of deformation or failure of the bolted joint. This is particularly important in applications where maintaining parallelism and uniform distribution of force is crucial.

2. Shock Absorption One of the standout features of conical disc spring washers is their ability to absorb shocks and vibrations. When installed under fasteners, these washers can adjust to changes in load, helping protect both the fasteners and the components they secure.

3. Compensation for Wear Over time, materials can wear down, leading to gaps between attached components. Conical disc spring washers can compensate for these gaps by maintaining tension, consequently prolonging the lifespan of the assembly.

4. Versatile Applications Due to their unique properties, conical disc spring washers are utilized in a broad range of applications—from automotive engines to machinery, electronic devices, and structural systems. Their versatility allows them to adapt to various operational environments, including high-stress and high-temperature situations.

conical disc spring washer company

Key Considerations When Choosing Conical Disc Spring Washers

When selecting conical disc spring washers for a specific application, there are several factors to consider

- Material Selection The choice of material greatly impacts the washer's performance. Stainless steel offers excellent corrosion resistance, making it ideal for outdoor or humid environments, while carbon steel may be suitable for indoor applications.

- Load Requirements Understanding the specific load requirements for the application is crucial. The selected washer must be able to handle both static and dynamic loads effectively.

- Compatibility with Fasteners Ensure that the washer is compatible with the fasteners being used, including bolt diameter and thread pitch. This compatibility ensures that the washer can perform its intended function without causing damage or loosening.

Conclusion

Conical disc spring washers are a remarkable innovation in the realm of mechanical components, providing a robust solution for load distribution and flexibility. Their ability to absorb shocks and maintain tension over time makes them invaluable in various industries. Whether you are involved in manufacturing, construction, or maintenance, understanding and utilizing these spring washers can enhance the performance and longevity of your assemblies.

As with any component, proper selection and installation are critical to achieving optimal performance. With the right conical disc spring washer, you can significantly improve the reliability and effectiveness of your mechanical systems, ensuring that they withstand the rigors of everyday use. The future of engineering lies in understanding and harnessing the potential of such innovative components, and conical disc spring washers are certainly at the forefront of that evolution.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024