Analyzing the Strength Characteristics of Self-Tapping Screws in China’s Manufacturing Sector

Understanding the Strength of China’s Self-Tapping Screws

Self-tapping screws are essential fasteners used in various industries, from construction to electronics. They are uniquely designed to create their own thread in the material they are being driven into, eliminating the need for pre-drilling. Among the global producers of self-tapping screws, China holds a prominent position. This article delves into the various factors that contribute to the strength and reliability of self-tapping screws manufactured in China.

Manufacturing Standards and Techniques

The strength of self-tapping screws is largely influenced by the materials used and the manufacturing techniques employed. Chinese manufacturers have adopted modern manufacturing practices while adhering to international standards. The manufacturing process involves carefully selecting high-quality steel alloys that provide the necessary tensile and shear strength. Common materials include carbon steel, stainless steel, and alloy steel. These materials offer durability and resistance to corrosion, which is crucial for maintaining strength over time, especially in varying environmental conditions.

Additionally, advanced manufacturing processes such as cold forging and heat treatment are routinely utilized to enhance the mechanical properties of the screws. Cold forging improves the grain structure of the metal, resulting in higher yield strength, while heat treatment can further increase hardness and toughness. These methods ensure that the self-tapping screws can withstand significant forces without deforming or breaking.

Thread Design and Geometry

The design of the screw threads plays a critical role in determining the strength and performance of self-tapping screws. Chinese manufacturers invest in research and development to create innovative thread designs that optimize engagement with the base material. The thread pitch, depth, and angle are engineered to provide maximum holding power and resistance to pull-out forces.

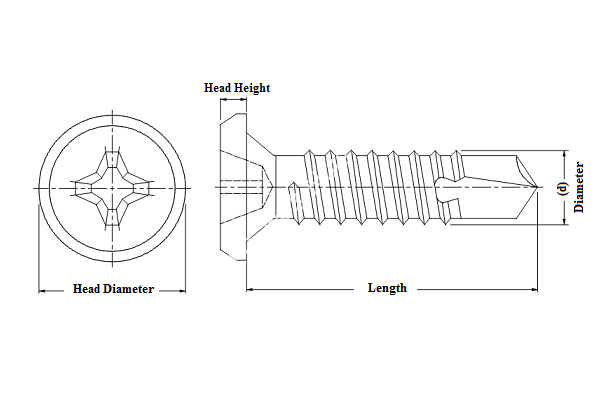

Self-tapping screws typically feature sharp threads and a cutting point that enables easy penetration into the substrate material. The screw's geometry is also designed to distribute stress evenly across the threads, reducing the risk of stripping or failure under load. This thoughtful design process is crucial for applications requiring reliable fastening solutions, such as in the automotive and aerospace industries.

china self tapping screw strength

Testing and Quality Control

Quality control is an indispensable part of the self-tapping screw manufacturing process in China. Rigorous testing is conducted to evaluate the screws' strength and performance characteristics. Manufacturers often perform tensile tests, torque tests, and pull-out tests to ensure that the screws meet the required strength standards.

Furthermore, adherence to international certifications, such as ISO 9001, demonstrates a commitment to maintaining high-quality production practices. Many Chinese manufacturers also engage in third-party testing to validate their products' performance against global benchmarks. This level of scrutiny provides customers with confidence in the reliability and strength of self-tapping screws produced in China.

Applications and Market Reach

The strength of self-tapping screws means they can be used in an array of applications. From HVAC installations to electronic devices, their versatility allows for widespread usage. China’s self-tapping screws are exported globally, finding their way into markets in Europe, North America, and beyond. Their competitive pricing, combined with their reliability, has made Chinese self-tapping screws a popular choice among manufacturers and builders worldwide.

Moreover, as industries evolve, the demand for stronger and more durable fasteners continues to grow. This has prompted Chinese manufacturers to innovate further, developing specialized screws to meet specific industry requirements. For instance, screws designed for marine applications undergo additional treatment to enhance corrosion resistance, reflecting the industry’s diverse needs.

Conclusion

In conclusion, the strength of self-tapping screws manufactured in China is a product of refined manufacturing techniques, advanced thread design, stringent quality control, and adaptability to various applications. As a leading producer, China continues to deliver reliable fastening solutions that satisfy the demands of numerous industries. The ongoing commitment to quality and innovation positions Chinese self-tapping screws favorably in the global market, ensuring they remain a staple in construction and manufacturing practices for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024