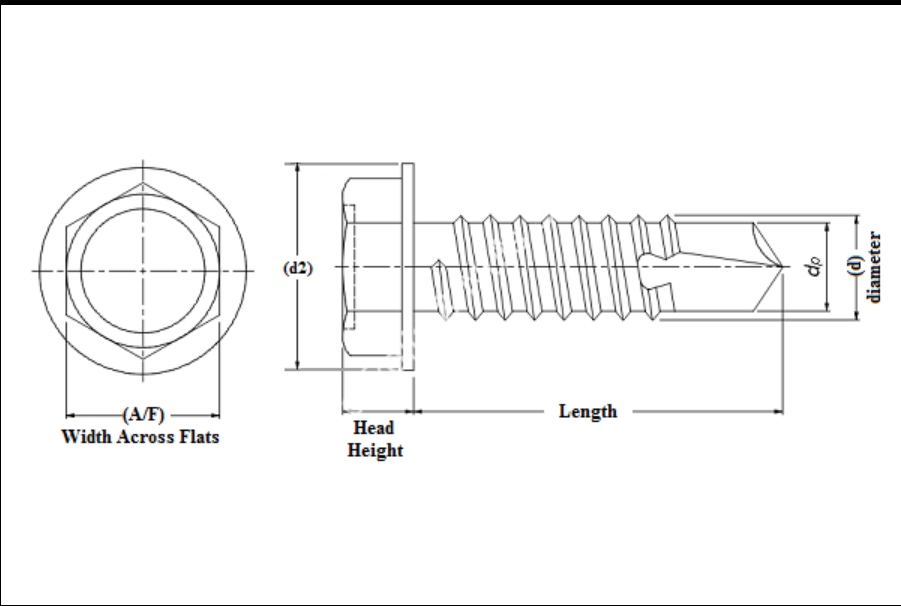

china 10 16x3 4 self drilling screw

The Evolution of Self-Drilling Screws in China 2010-2016

Self-drilling screws have become an essential component in the world of construction and manufacturing, and their development in China from 2010 to 2016 is a testament to both technological advancement and a growing demand in various industries. This period marked significant changes in the production methods, material quality, and applications of self-drilling screws, enabling China to strengthen its position as a global manufacturing powerhouse.

Between 2010 and 2016, China's manufacturing sector witnessed rapid technological advancements. Factories began adopting more automated processes, which increased efficiency and reduced production costs. The advent of computer-aided design (CAD) and computer numerical control (CNC) significantly improved the precision of self-drilling screws. This meant that the threads, tip designs, and overall geometry of screws could be optimized for specific materials and applications, leading to better performance and reliability.

Moreover, manufacturers started to invest in research and development to enhance the properties of the screws. The use of advanced coatings, such as zinc plating and epoxy finishes, not only improved corrosion resistance but also enhanced the aesthetic appeal of the screws. These improvements made self-drilling screws suitable for a wider range of applications, from residential construction to automotive assembly.

2. Increased Demand

The demand for self-drilling screws saw a considerable surge during this period due to the booming construction and manufacturing sectors in China. The rapid urbanization and infrastructure development projects across the country called for reliable fastening solutions. Self-drilling screws gained popularity for their ability to eliminate the need for pre-drilling, significantly speeding up the installation process. This feature was particularly valuable in large-scale projects such as skyscrapers, bridges, and public transportation systems.

china 10 16x3 4 self drilling screw

Internationally, emerging markets also began to recognize the benefits of self-drilling screws, leading to increased exports from China. Chinese manufacturers geared up to meet this global demand by ensuring that their products adhered to international quality standards, such as ISO certifications. As a result, self-drilling screws manufactured in China gained acceptance and trust in various international markets.

3. Competition and Market Dynamics

The period from 2010 to 2016 also saw heightened competition in the self-drilling screw market. Numerous manufacturers emerged, and existing firms expanded their production capacities to capture a larger market share. This competitive landscape encouraged innovation, with companies constantly seeking ways to differentiate their products.

Quality control mechanisms became a focal point for manufacturers looking to establish themselves as reliable suppliers. Enhanced quality checks ensured that every batch of screws met the required specifications, thereby reducing the risks associated with faulty products. Such diligence not only bolstered the reputation of Chinese manufacturers but also contributed to the overall improvement in product quality within the industry.

4. Future Prospects

Looking beyond 2016, the self-drilling screw market in China continues to evolve. The increasing focus on sustainability and environmental considerations is prompting manufacturers to explore eco-friendly materials and production methods. Additionally, the rise of prefabricated building materials and modular construction techniques is likely to further boost the demand for efficient fastening solutions like self-drilling screws.

In conclusion, the years 2010 to 2016 were pivotal for the self-drilling screw industry in China. Technological advancements, increasing demand, competitive dynamics, and a focus on quality propelled the industry forward. As the construction and manufacturing sectors continue to evolve, it is clear that self-drilling screws will remain a fundamental component, driving efficiency and innovation for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024