cheap spring washer types

Understanding Cheap Spring Washer Types

When it comes to securing various mechanical assemblies, spring washers are an essential component that provides vital tension and vibration resistance. Among the different types available on the market, cheap spring washers are particularly popular among DIY enthusiasts and cost-conscious professionals. This article explores the various types of cheap spring washers, their applications, and how to choose the right one for your needs.

Types of Spring Washers

1. Flat Spring Washers Flat spring washers are the most straightforward type. They are made from a flat strip of flexible material that can compress and expand under load. Their primary function is to provide a flexible cushion between the bolt head or nut and the surface underneath. This helps distribute the load and reduces the risk of crushing or deformation of other components. They are widely used in furniture assembly, automotive applications, and electrical appliances.

2. Conical Spring Washers Conical or Belleville washers are designed in a cone shape and can be stacked to create a desired spring force. They are particularly effective in applications that require a higher load capacity. When used in pairs, they can handle both tension and compression loads, making them great for heavy machinery, aerospace, and automotive industries. Despite being slightly more expensive than flat washers, they still offer a cost-effective solution for heavy-duty applications.

3. Lock Washers Lock washers, including split and toothed designs, feature sharp edges or protrusions that grip the bolt or nut and prevent them from loosening due to vibration. Although they fall into the category of lock devices rather than traditional spring washers, they are often paired with spring washers to enhance stability. These are particularly useful in automotive applications, where vibrations are common, helping to keep components securely in place.

4. Wave Washers Wave washers, which have a wavy shape, provide a unique spring action. The multiple waves in the washer compress under load, creating a non-flat surface that maintains clamping force even when subjected to vibration. These types are often used in applications requiring flexibility and resilience, such as electrical connectors and valve assemblies.

5. Disc Spring Washers Similar to conical washers, disc spring washers are flat yet have a designed curvature that provides excellent load-bearing capacity. They can be used in high-performance applications where precise tension and deflection are required. Their affordability makes them a popular choice in both industrial and consumer goods.

cheap spring washer types

Choosing the Right Spring Washer

When selecting a cheap spring washer, specific factors should be considered

- Material Common materials include stainless steel, zinc-plated steel, and plastic. Stainless steel is corrosion-resistant and suitable for outdoor conditions, while zinc-plated options provide a balance of cost and rust resistance.

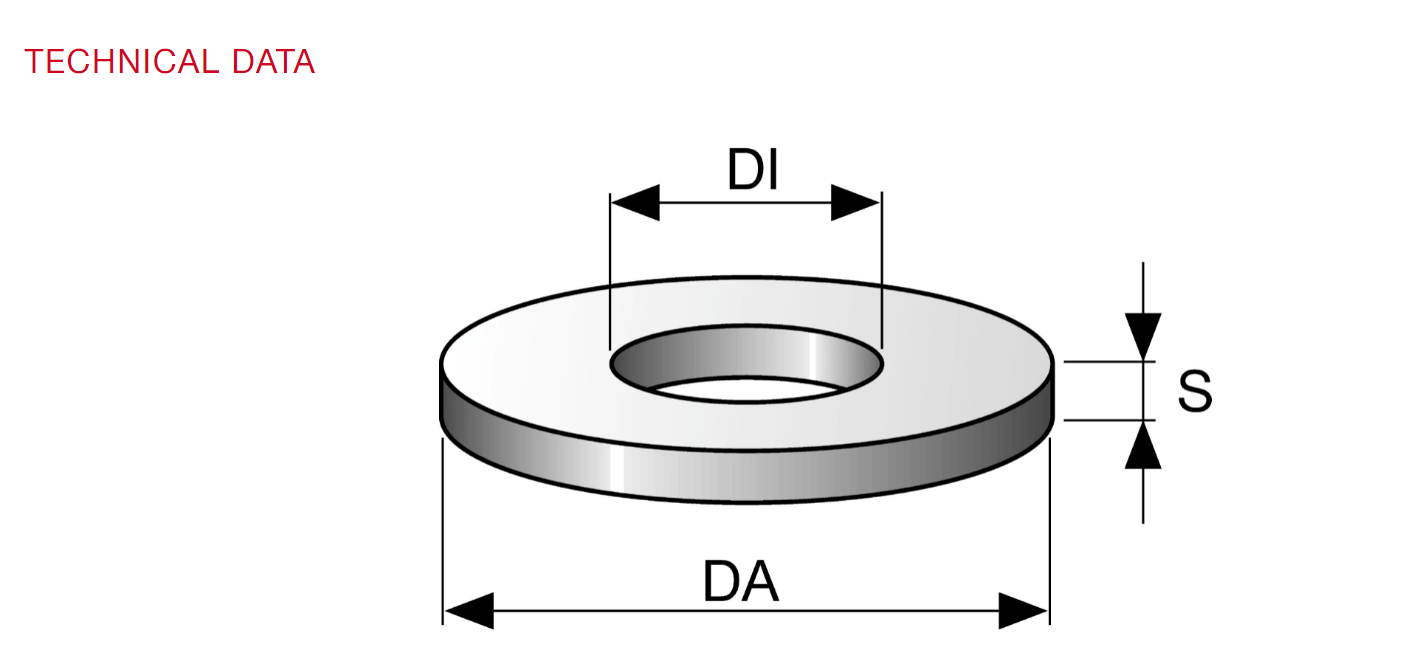

- Size The inner diameter of the washer should match the bolt size, while the outer diameter should accommodate the intended load.

- Load Requirements Understand the mechanical forces the washer must endure. For light, non-critical applications, flat washers may suffice. For more robust mechanisms, consider conical or wave washers.

- Environmental Conditions In humid or corrosive environments, opt for materials that can withstand such conditions to ensure longevity.

Conclusion

Cheap spring washers play a crucial role in various mechanical applications, from securing bolts in furniture to stabilizing components in machinery. By understanding the different types and their specific uses, one can make informed decisions that balance cost and performance. Whether you need a simple flat washer or a more complex disc spring washer, the right choice will enhance the durability and reliability of your projects. Always consider the material, size, load requirements, and environment to select the most suitable spring washer for your application.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024